Durable polyurethane finish capable of resisting marine-atmosphere environment, and preparation method thereof

A polyurethane topcoat, marine atmosphere technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of easy aging, short validity period, loss of gloss, etc., to reduce shrinkage cavities and surface defects of coatings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

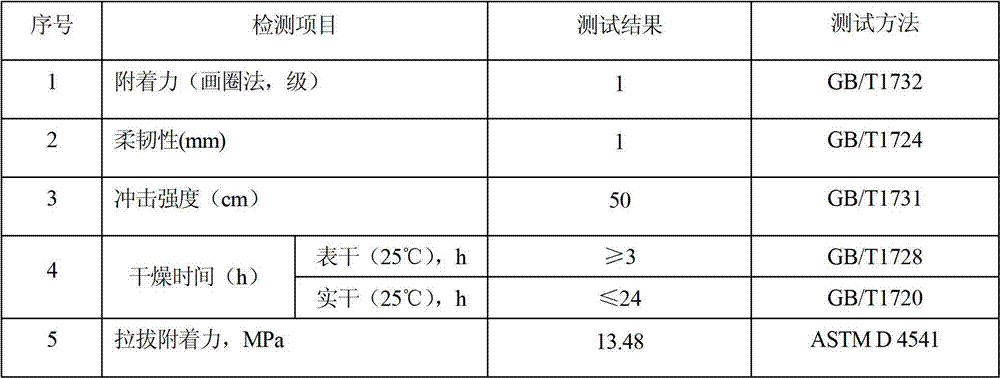

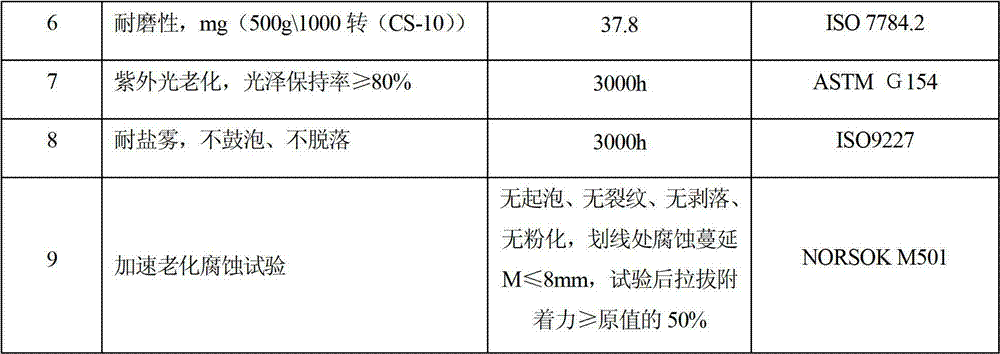

Examples

Embodiment 1

[0106] A long-lasting polyurethane topcoat resistant to marine and atmospheric environments: the weight percentage of component A is:

[0107] HDI trimer isocyanate: 94.5%;

[0108] Corrosion inhibitor: 0.5%;

[0109] Urethane grade butyl acetate: 5%;

[0110] The weight percentage of liquid B is:

[0111] Polyurethane resin hydroxyl component: 40%;

[0112] Xylene: 9.09%;

[0113] Polymethacrylate solution: 0.1%;

[0114] Fluorine-containing organic silicon solution: 0.1%;

[0115] No silicone acrylic polymer: 0.1%;

[0116] Polysiloxane-polyether copolymer: 0.01%;

[0117] Alkaline and acidic fatty acid surfactant mixture: 1.4%;

[0118] Ultraviolet light absorber: 0.2%;

[0119] Light stabilizer: 1%;

[0120] Polyurethane curing accelerator: 0.5%

[0121] Polyethylene micronized wax: 0.3%

[0122] PTFE micronized wax: 0.2%

[0123] Precipitated barium sulfate: 10%;

[0125] Sericite powder: 10%;

[0126] Rutile titanium dioxide: 17%;

[0127] The ingredients in use consi...

Embodiment 2

[0134] A long-lasting polyurethane topcoat resistant to marine and atmospheric environments, the weight percentage of component A is:

[0135] HDI trimer isocyanate: 92.4%;

[0136] Corrosion inhibitor: 0.6%;

[0137] Urethane grade butyl acetate: 7%;

[0138] The weight percentage of liquid B is:

[0139] Polyurethane resin hydroxyl component: 45%;

[0140] Xylene: 7%;

[0141] Polymethacrylate solution: 0.15%;

[0142] Fluorine-containing organic silicon solution: 0.15%;

[0143] Silicone-free acrylic polymer: 0.15%;

[0144] Polysiloxane-polyether copolymer: 0.05%;

[0145] Alkaline and acidic fatty acid surfactant mixture: 1.3%;

[0146] Ultraviolet light absorber: 0.4%;

[0147] Light stabilizer: 1.1%;

[0148] Polyurethane curing accelerator: 1%

[0149] Polyethylene micronized wax: 0.4%

[0150] PTFE micronized wax: 0.3%

[0151] Precipitated barium sulfate: 8%;

[0152] Quartz powder: 10%;

[0153] Sericite powder: 10%;

[0154] Rutile titanium dioxide: 15%;

[0155] The ingredient composition ...

Embodiment 3

[0158] A long-lasting polyurethane topcoat resistant to marine and atmospheric environments, the weight percentage of component A is:

[0159] HDI trimer isocyanate: 91.3%;

[0160] Corrosion inhibitor: 0.7%;

[0161] Urethane grade butyl acetate: 8%;

[0162] The weight percentage of liquid B is:

[0163] Polyurethane resin hydroxyl component: 50%;

[0164] Xylene: 8.12%;

[0165] Polymethacrylate solution: 0.2%;

[0166] Fluorine-containing organic silicon solution: 0.2%;

[0167] No silicone acrylic polymer: 0.2%;

[0168] Polysiloxane-polyether copolymer: 0.08%;

[0169] Alkaline and acidic fatty acid surfactant mixture: 0.9%;

[0170] Ultraviolet light absorber: 0.6%;

[0171] Light stabilizer: 1.3%;

[0172] Polyurethane curing accelerator: 1.5%

[0173] Polyethylene micronized wax: 0.5%

[0174] PTFE micronized wax: 0.4%

[0175] Precipitated barium sulfate: 9%;

[0176] Quartz powder: 8%;

[0177] Sericite powder: 7%;

[0178] Rutile titanium dioxide: 12%;

[0179] The ingredients in use consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com