A method for producing oxygen by electrolysis of carbon dioxide

A carbon dioxide and oxygen technology, applied in the field of electrochemistry, can solve the problems of low photoelectric catalytic conversion efficiency, low reaction rate, hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

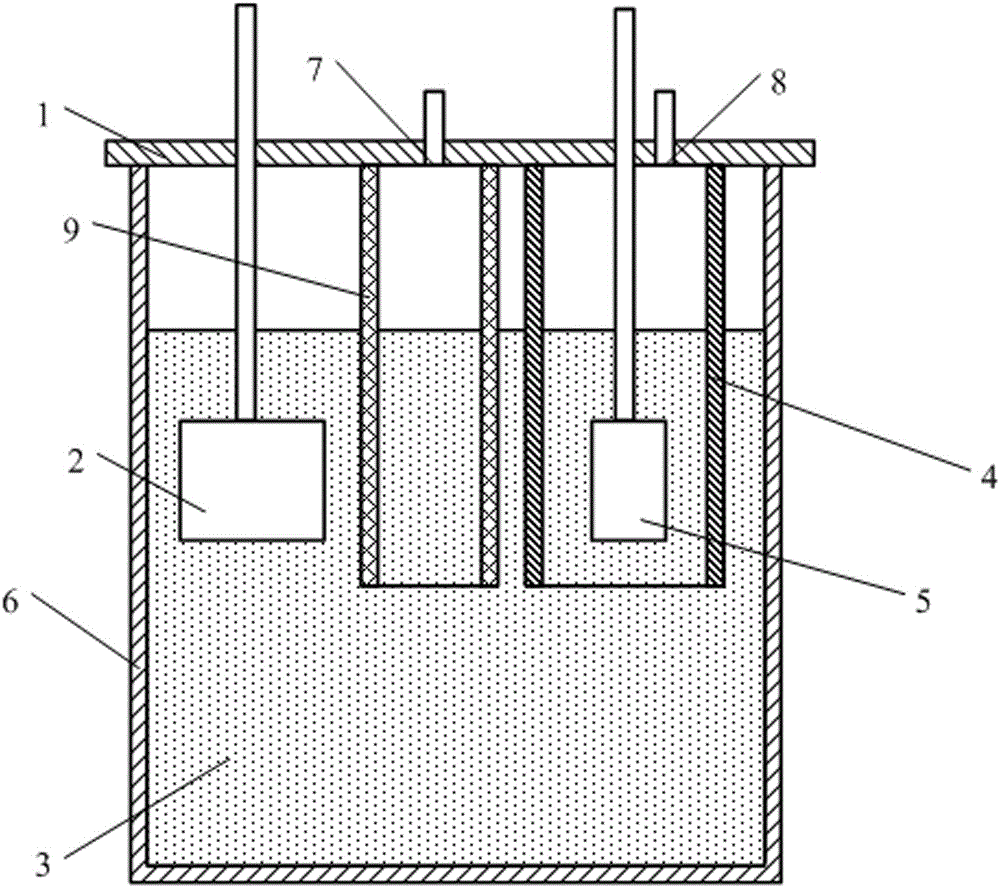

[0024] A device that electrolyzes carbon dioxide to produce oxygen, such as figure 1 As shown, the graphite crucible 6 is included, the top of the graphite crucible 6 is provided with a nickel crucible cover 1, and the nickel crucible 1 cover is provided with CO 2 Inlet 7 and oxygen outlet 8, also be provided with CO on the bottom surface of nickel crucible lid 1 2 Channel 9 and anode cover 4, CO 2 Import 7 with CO 2 Channel 9 communicates, oxygen outlet 8 communicates with anode cover 4; anode 5 and cathode 2 are inserted in graphite crucible 6 and anode 5 is inserted in anode cover 4;

[0025] Combine anhydrous LiF and Li 2 CO 3 Mix evenly at a molar ratio of 0.5:1 to obtain a mixed material;

[0026] Add additives to the mixed material and mix uniformly to make electrolyte molten salt; the additive accounts for 2% of the total weight of the electrolyte molten salt; the additive is LiCl;

[0027] Using the above device, the graphite crucible is used as the electrolytic...

Embodiment 2

[0030] The device for preparing oxygen by electrolysis of carbon dioxide is the same as in Example 1;

[0031] Combine anhydrous LiF and Li 2 CO 3 Mix evenly at a molar ratio of 1.5:1 to obtain a mixed material;

[0032] Add additives to the mixed material and mix uniformly to make electrolyte molten salt; the additive accounts for 15% of the total weight of the electrolyte molten salt; the additive is NaF;

[0033] Using the above device, the graphite crucible is used as the electrolytic cell, the electrolyte molten salt is placed in the electrolytic cell, heated to 690~700°C, and the CO 2 Cylinders and CO 2 Inlet connectivity, then through the CO 2 The channel feeds CO into the electrolyte molten salt 2 gas, and Ni electrode is used as cathode, Fe-Ni alloy electrode is used as anode, and the electrolyte molten salt is energized for electrolysis; the current density is controlled at 0.1A / cm during electrolysis 2 , the incoming CO 2 The pressure of the gas is 0.1~0.12MP...

Embodiment 3

[0036] The device for preparing oxygen by electrolysis of carbon dioxide is the same as in Example 1;

[0037] Combine anhydrous LiF and Li 2 CO 3 Mix evenly at a molar ratio of 1:1 to obtain a mixed material;

[0038] Add additives to the mixed material and mix uniformly to make electrolyte molten salt; the additive accounts for 3% of the total weight of the electrolyte molten salt; the additive is KF;

[0039] Using the above device, the graphite crucible is used as the electrolytic cell, the electrolyte molten salt is placed in the electrolytic cell, heated to 690~700°C, and the CO 2 Cylinders and CO 2 Inlet connectivity, then through the CO 2 The channel feeds CO into the electrolyte molten salt 2 Gas, and use Ni electrode as cathode, using Fe-Ni-Al 2 o 3 The alloy electrode is the anode, and the electrolyte molten salt is energized for electrolysis; the current density is controlled at 0.2A / cm during electrolysis 2 , the incoming CO 2 The pressure of the gas is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com