Top-emitting organic electroluminescent device and preparation method thereof

A technology of electroluminescence and top emission, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc. It can solve the problems of unfavorable carrier injection and insufficient transmittance, maintain stability and improve injection efficiency , the effect of high light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

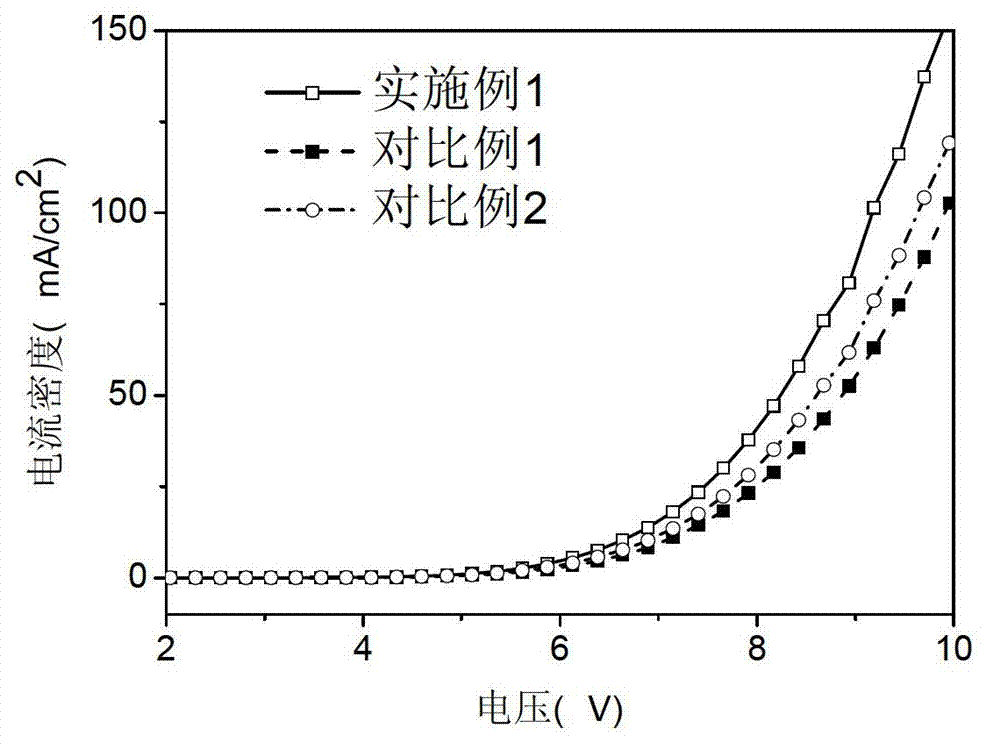

Embodiment 1

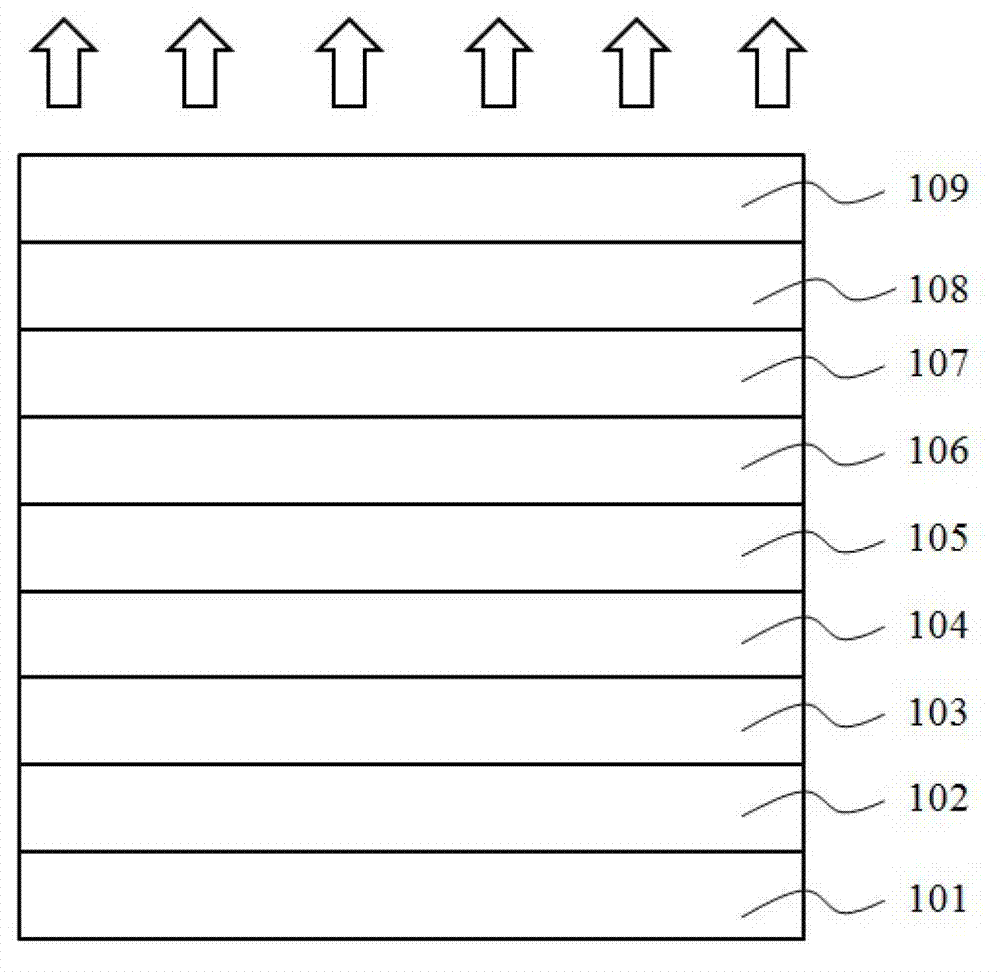

[0050] The structure of the top emission organic electroluminescent device of this embodiment is: glass / Al / LiN 3 :Alq 3 / BAlq / NPB:Ir(MDQ) 2 (acac) / NPB / F4-TCNQ:m-MTDATA / ReO 3 / ITO

[0051] The fabrication method of the top emission organic electroluminescent device is as follows:

[0052] 1. Use detergent, deionized water, isopropanol, and acetone to ultrasonically clean the glass substrate for 20 minutes, and then dry it with nitrogen;

[0053] 2. After the glass is cleaned, it is placed in a vacuum thermal sputtering system, and the cathode layer (the material is Al, the thickness is 70nm), the electron transport layer (the material is LiN 3 Doped to Alq at a mass ratio of 5% 3 , expressed as LiN 3 :Alq 3 ; thickness is 30nm), hole blocking layer (material is BAlq; thickness is 10nm), light-emitting layer (material is Ir(MDQ) 2 (acac) is doped into the NPB host material as a dopant material, expressed as NPB:Ir(MDQ) 2 (acac), Ir(MDQ) 2 (acac) doping mass ratio is 5%...

Embodiment 2

[0056] The top-emitting organic electroluminescent device of this embodiment has a structure of: glass / Ag / CsN 3 :Bphen / BPhen / CBP:FIrPic / TPD / F4-TCNQ:MeO-TPD / WO 3 / IZO

[0057] The fabrication method of the top emission organic electroluminescent device is as follows:

[0058] 1. Use detergent, deionized water, isopropanol, and acetone to ultrasonically clean the glass substrate for 20 minutes, and then dry it with nitrogen;

[0059] 2. After the glass is cleaned, it is placed in a vacuum thermal sputtering system, and the cathode layer (the material is Ag with a thickness of 100nm) and the electron transport layer (the material is CsN) are sequentially evaporated on the glass surface. 3 Doped into Bphen at a mass ratio of 30%, expressed as CsN 3 : Bphen; the thickness is 60nm), the hole blocking layer (the material is BPhen; the thickness is 10nm), the light-emitting layer (the material is FIrPic is doped into the CBP host material as the doping material, expressed as CBP: F...

Embodiment 3

[0062] The top emission organic electroluminescent device of the present embodiment has a structure of: glass / Ag-Mg / Li 2 CO 3 :TPBi / TPBi / NPB:Ir(MDQ) 2 (acac) / TPD / F4-TCNQ:2-TNATA / MoO 3 / AZO

[0063] The fabrication method of the top emission organic electroluminescent device is as follows:

[0064] 1. Use detergent, deionized water, isopropanol, and acetone to ultrasonically clean the glass substrate for 20 minutes, and then dry it with nitrogen;

[0065] 2. After the glass is cleaned, it is placed in a vacuum thermal sputtering system, and the cathode layer (the material is Ag-Mg, the thickness is 200nm), the electron transport layer (the material is Li 2 CO 3 Doped into TPBi according to the mass ratio of 20%, expressed as Li 2 CO 3 :TPBi; thickness is 10nm), hole blocking layer (material is TPBi; thickness is 40nm), light emitting layer (material is Ir(MDQ) 2 (acac) is doped into the NPB host material as a dopant material, expressed as NPB:Ir(MDQ) 2 (acac), Ir(MDQ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com