Biological slime stripping agent for water treatment, and preparation method thereof

A biological slime and stripping agent technology, applied in the directions of botanical equipment and methods, chemicals for biological control, biocides, etc., can solve the problems of high cost and high price, and achieve safe use, efficient sterilization, Enhanced effect of sterilization and slime peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 10

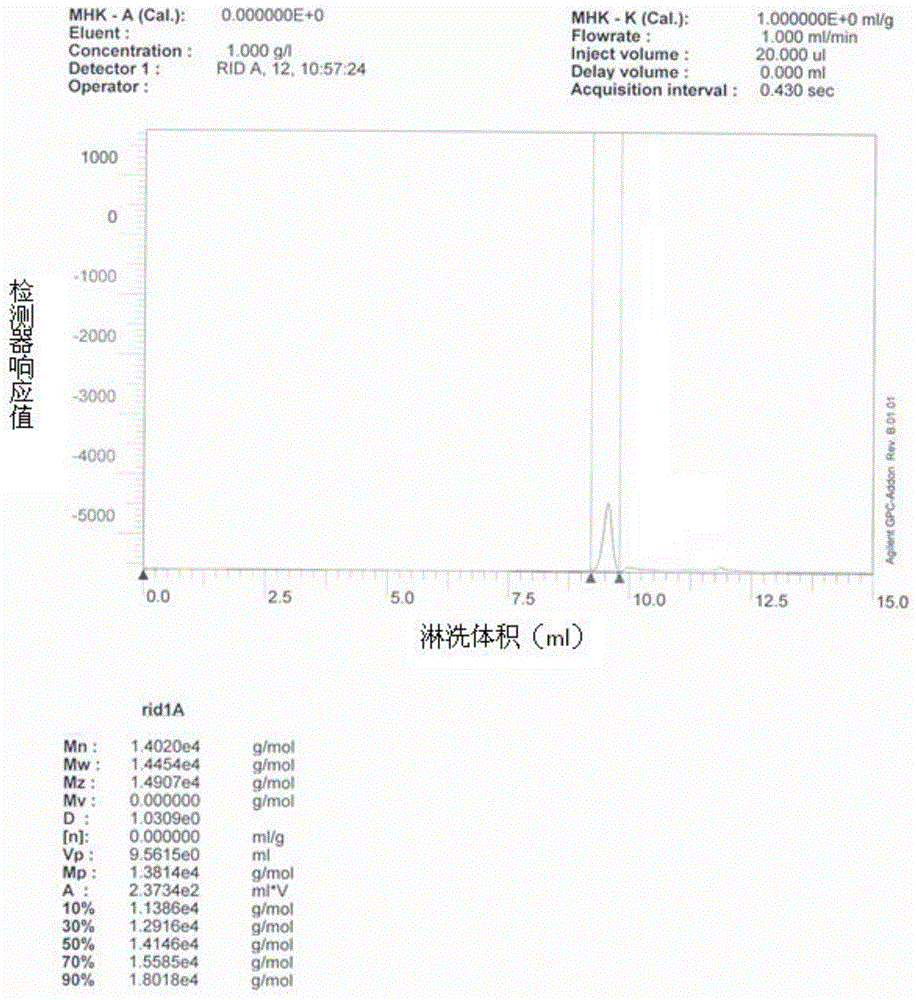

[0032] The preparation of embodiment 1 dodecyl polyhexamethylene guanidine hydrochloride

[0033] In a 1000ml four-necked flask equipped with mechanical stirring, reflux condenser, thermometer and ammonia absorbing device, add 117.2g (99%, 1.0mol) of hexamethylenediamine and 60g of ethylene glycol. Then 20.68 g of 1-chlorododecane (99%, 0.10 mol) was added dropwise at room temperature. After the addition, the temperature was raised to 55 ° C, and the reaction was kept for 3 hours. Then 96.50 g of guanidine hydrochloride (99%, 1.0 mol) was added, and the temperature was raised to 80°C, react for 2h; then raise the temperature to 160°C, continue to react for 6h. Finally, 140 g of water was added and stirred evenly to obtain a dodecyl polyhexamethylene guanidine hydrochloride product (APHG) with a content of 50%.

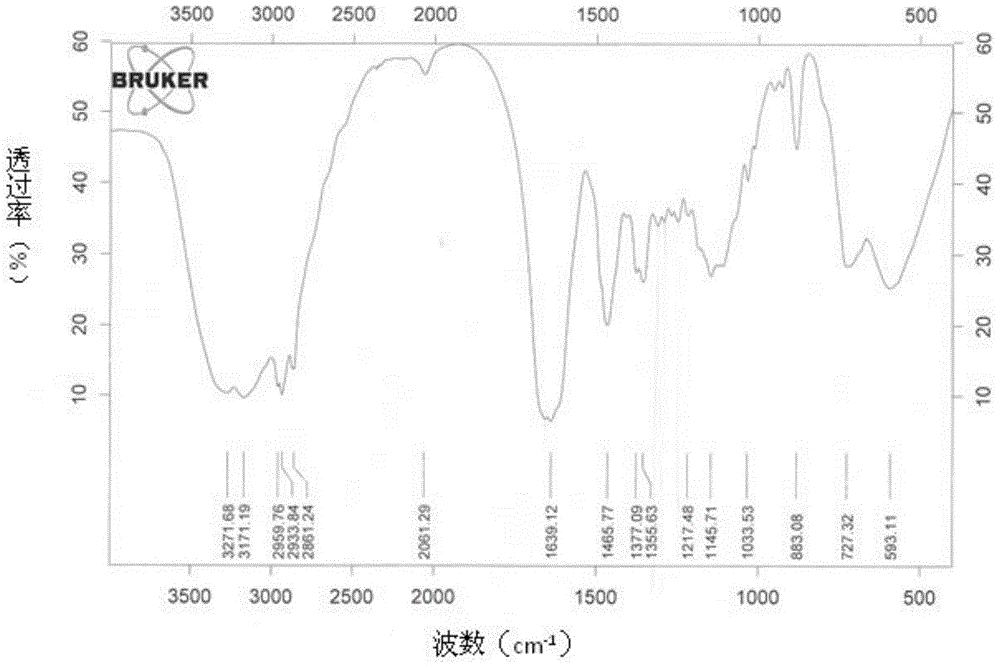

[0034] From its infrared spectrum (attached figure 2 ) analysis shows: 3271.68cm -1 and 3171.19cm -1 It is the out-of-plane deformation vibration absorption peak ...

Embodiment 2

[0035] The preparation of embodiment 2 biological slime stripping agent

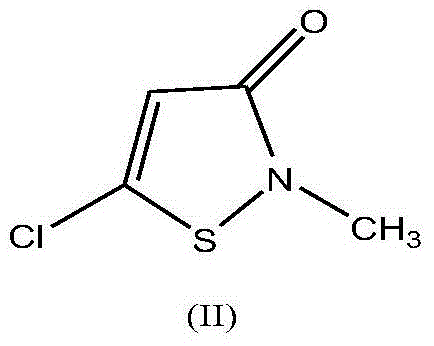

[0036] At room temperature, add alkyl polyhexamethylene guanidine hydrochloride and water to the reaction flask in turn, adjust the pH to ≤6 with hydrochloric acid, then add solvent, stir evenly, add isothiazolinone and organic bromide, stir to completely dissolve Finally, the water treatment biological slime stripping agent of the present invention is obtained. According to the different components and composition ratios (mass percentage) shown in Table 1 below, the preparation method is used to prepare, and the product numbers of the prepared biological slime stripping agents are A1-A6 respectively:

[0037] Table 1 The composition ratio of different biological slime stripping agents

[0038]

[0039]Note: APHG——the alkyl polyhexamethylene guanidine hydrochloride product (50%) synthesized in Example 1; CIT / MIT——isothiazolinone, 14% industrial product; DBNPA——2,2-dibromo -3-Nitropropionamide; DBNE—...

Embodiment 4

[0047] Embodiment 4 Biological slime stripping performance test

[0048] The biological slime stripping performance test of the present invention adopts the following operation method: (1) Add bacteria and nutrients to the culture tank to cultivate the bacteria and algae; (2) After the cultivation is completed, connect the stainless steel test tube (the length of the tube is 25cm), Dynamic circulation, so that the stainless steel test tube breeds slime to the specified requirements, take out the test tube, dry at 40°C for 2 hours, and weigh; (3) Reconnect the weighed test tube to the test box, add the reagent, run for 24 hours, and then Take out the test tube, dry it at 40°C for 2h, and weigh it. The whole dynamic control parameters are: pH value=8.0~8.5, temperature 32±1℃, flow rate 1.0m / h. The test results are shown in Table 3:

[0049] It can be seen from the test data in Table 3 that under the experimental concentration conditions (the use cost of each agent is close at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com