Magnetic nano material with carbon shell layer and preparation method thereof

A magnetic and carbon shell technology is applied in the field of magnetic nanosphere materials and their rapid preparation, which can solve the problems of complex preparation process and long preparation time, and achieve the effects of increasing specific surface area, reducing separation cost and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

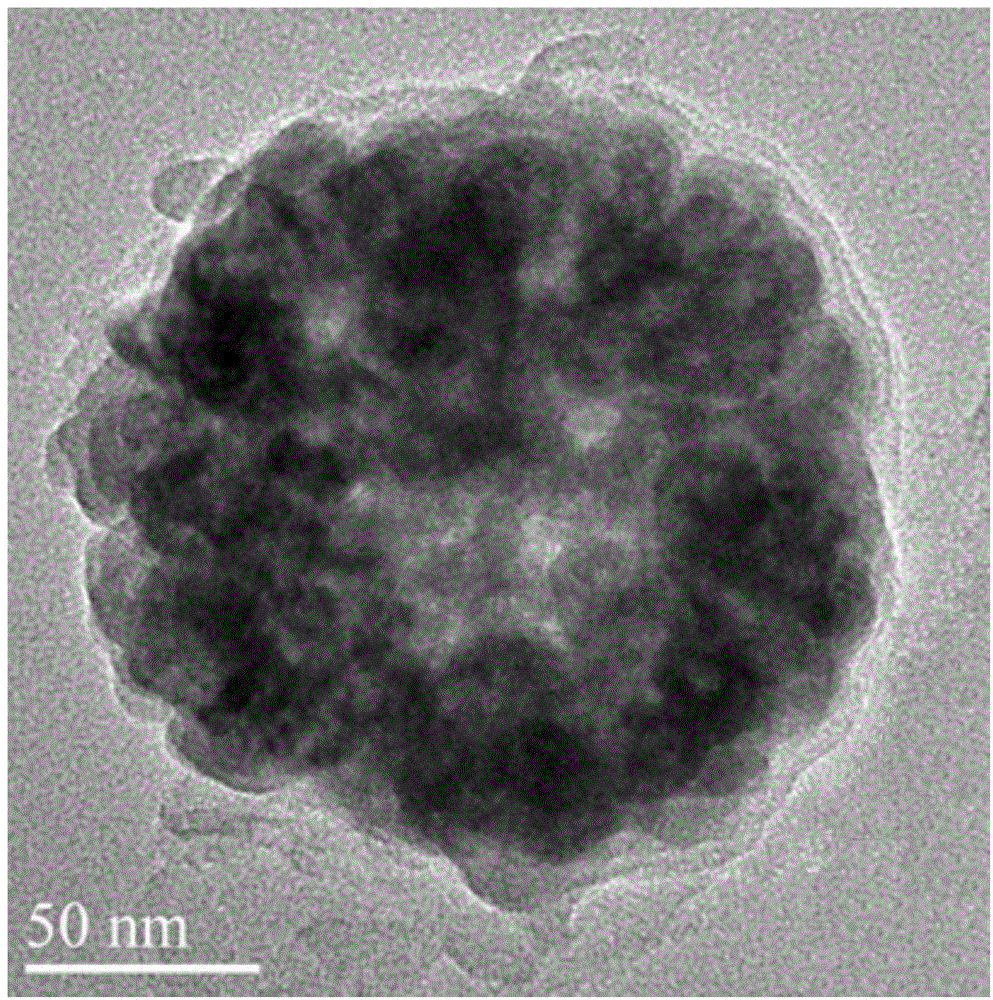

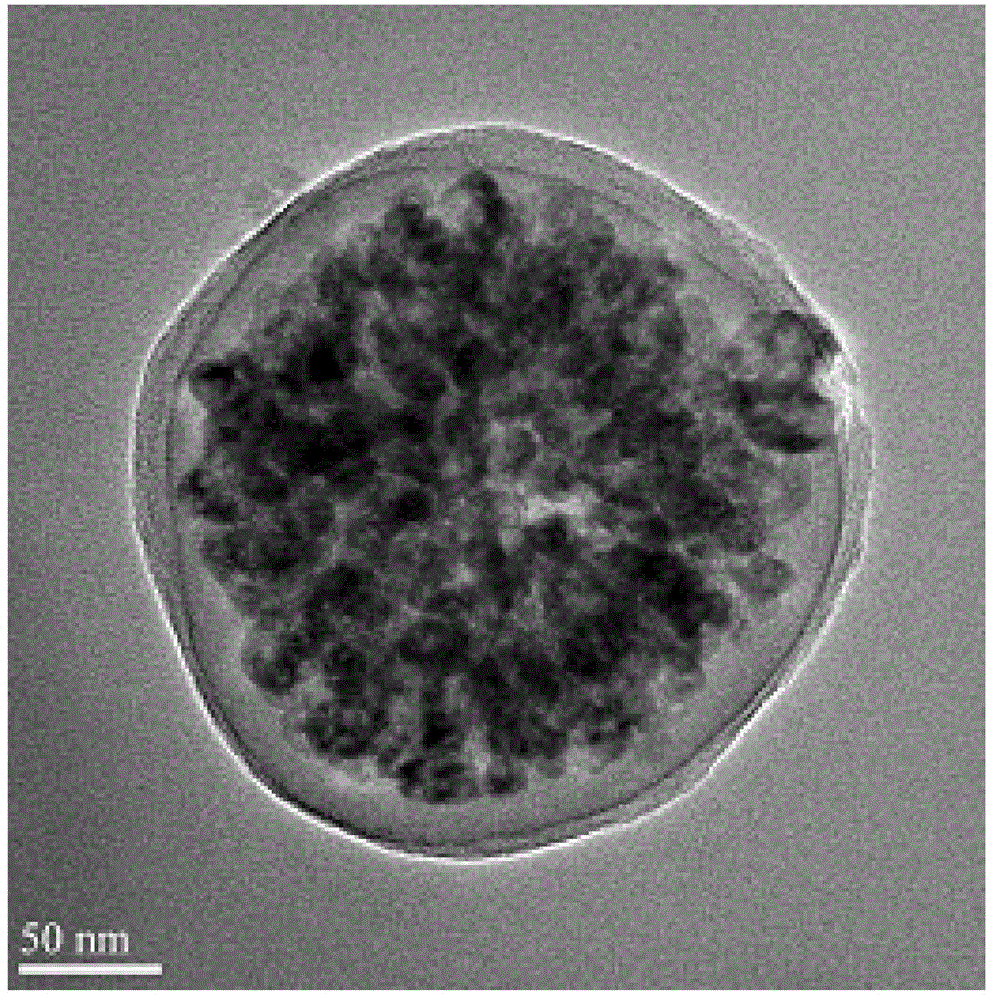

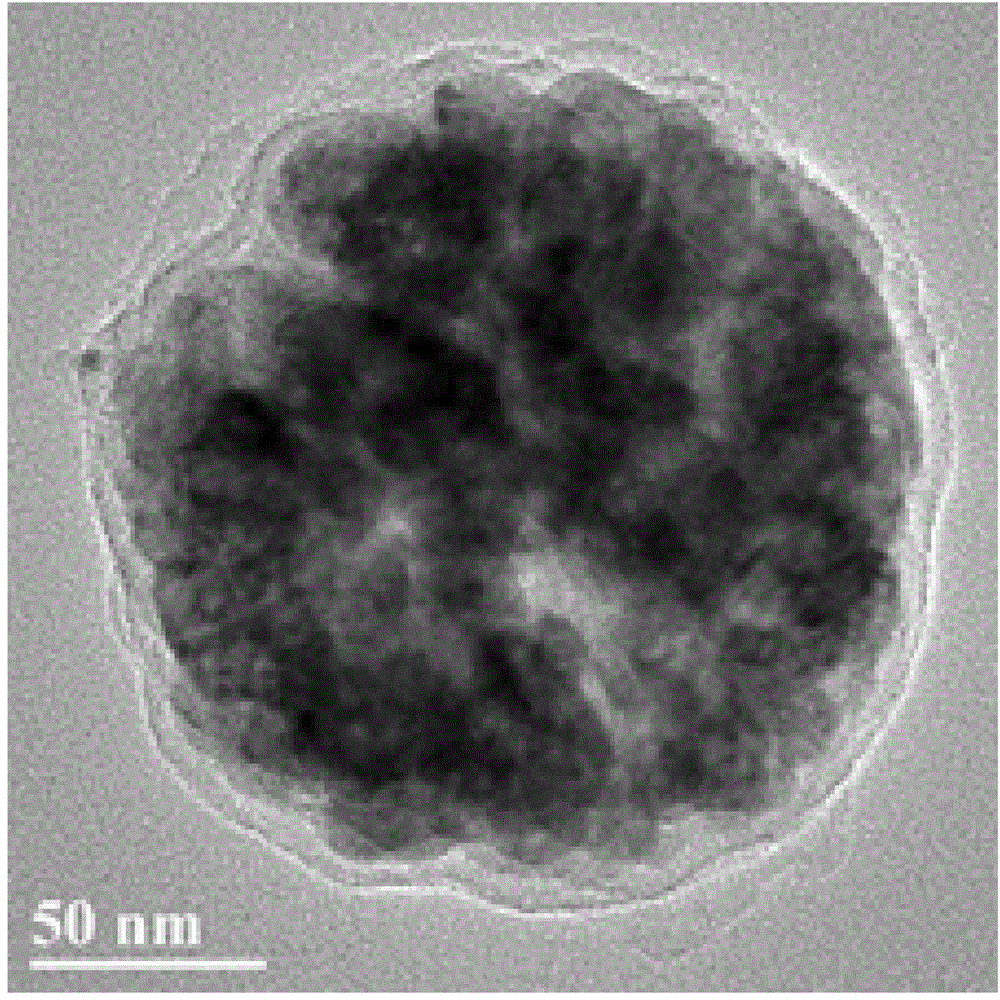

Image

Examples

Embodiment 1

[0023] (1) Weigh 16.2g FeCl 3 ·6H 2 O was dissolved in 83.8g deionized water to make a solution, and 4.9g of sodium acetate was weighed and dissolved in 45.1g of ethylene glycol to make a solution. The temperature of the water bath was 40°C and the stirring condition was added dropwise to the N 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 5 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0024] (2) Weigh the prepared magnetic Fe 3 o 4 Add 11.6g of granules to 38.4g of ethanol, and add 19g of glucose solution with a mass concentration of 10% and 10g of NaOH solution with a mass concentration of 10% at the water bath temperature of 50°C under stirring conditions. Stir for 3 hours, then sonicate for 50min under 150W ultrasonic power to complete Fe 3 o 4 The process of coa...

Embodiment 2

[0026] (1) Weigh 18.9g FeCl 3 ·6H 2 O was dissolved in 81.1g of deionized water to make a solution, and 5.7g of sodium acetate was weighed and dissolved in 44.3g of ethylene glycol to make a solution, which was added dropwise at a water bath temperature of 40°C under stirring conditions 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 5 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0027] (2) Weigh the prepared magnetic Fe 3 o 4 Add 13.9 g of granules to 36.1 g of ethanol, and simultaneously add 12 g of glucose solution with a mass concentration of 20% and 6 g of NaOH solution with a mass concentration of 20% at a water bath temperature of 50°C under stirring conditions. Stir for 3 hours, then ultrasonicate for 30min under 200W ultrasonic power to complete Fe 3 o 4 The p...

Embodiment 3

[0029] (1) Weigh 24.3g FeCl 3 ·6H 2 O was dissolved in 75.7g of deionized water to make a solution, 7.4g of sodium acetate was weighed and dissolved in 42.6g of ethylene glycol to make a solution, and the solution was added dropwise at a water bath temperature of 40°C under stirring conditions 2 In the protected reactor, after the dropwise addition, the mixed solution was put into an autoclave, crystallized at 180°C for 5 hours, then cooled naturally, washed with deionized water and ethanol three times, and dried in vacuum at 60°C for 8 hours. The obtained magnetic Fe 3 o 4 particles.

[0030] (2) Weigh the prepared magnetic Fe 3 o 4 Add 12.7g of granules to 37.3g of ethanol, and add 20g of starch solution with a mass concentration of 15% and 5.4g of a NaOH solution with a mass concentration of 30% at the same time at a water bath temperature of 50°C under stirring conditions. After the addition is completed, Thoroughly stir for 3 hours, then ultrasonicate for 40min unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com