Laser-assisted thin film preparation method and equipment

A laser-assisted, thin-film technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor stability, high cost of film preparation, low purity, etc., and achieve good stability and reliable product quality High performance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The thin film preparation method of the present invention will be described by taking deposition of microcrystalline silicon as an example. The preparation of microcrystalline silicon thin film is based on the organic precursor of silicon, such as silane, such as but not limited to: SiH 4 、Si 2 h 6 、Si 3 h 8 etc.; chlorosilanes such as SiH 2 Cl 2 , SiHCl 3 、SiCl 4 、Si 2 Cl 6 Wait.

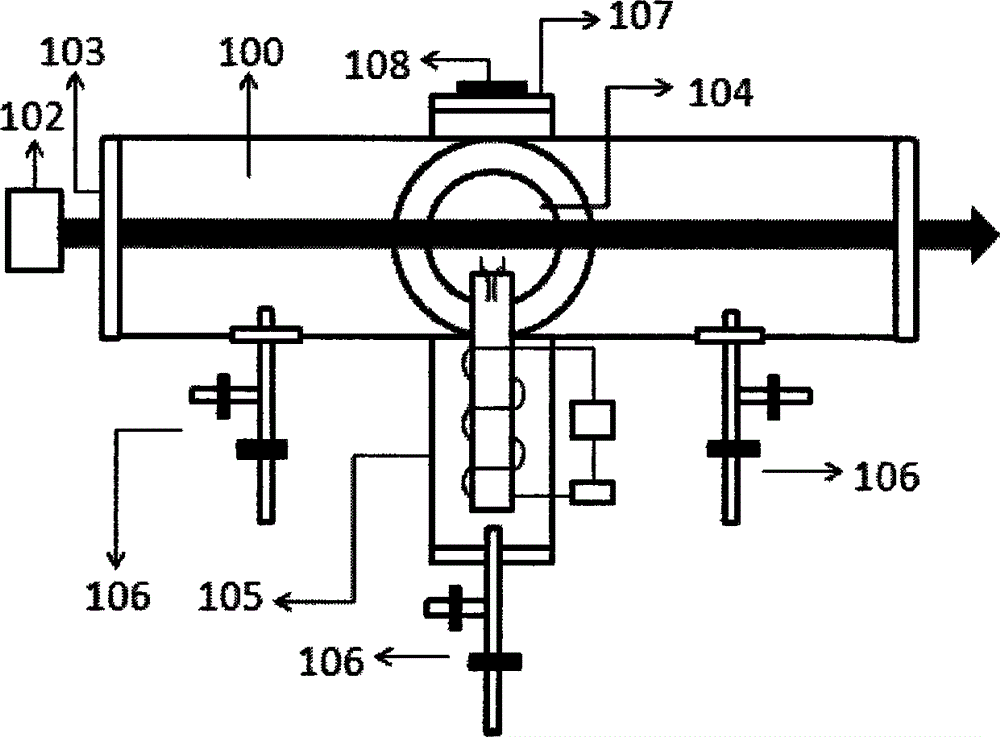

[0028] The organic precursor gas of silicon enters the plasma generator through the gas introduction device, and enters the reaction chamber after being activated by the plasma generator. In the reaction chamber, the laser beam emitted by the laser beam is heated, and the organic silicon is cracked to obtain Silicon atoms, silicon atoms are deposited on the substrate above the reaction chamber, and a film is grown on the substrate. In addition, the protective gas H 2 and sensitizing gas SF 6 . h 2 Confine the reactive gas and sensitizing gas near the center of the reaction cha...

Embodiment 2

[0033] The present invention will be further described by taking the preparation of copper indium gallium selenide thin film as an example.

[0034] The copper indium gallium selenide thin film is a compound film layer composed of various elements, and the precursor gases include organic copper, organic indium, organic gallium, and selenium vapor. For example, copper-containing organic precursors include, but are not limited to: Cu(C 11 h 19 o 2 ) 2 , Cu(CF 3 COCHCOCF 3 ) 2 , (C 5 h 5 )CuP(C 2 h 5 ) 3 , Cu(CF 3 COCHCOCH 3 ) 2 , Cu(CF 3 COCHCOCF 3 )P(CH 3 ) 3 etc.; Indium-containing organic precursors include, but are not limited to: triphenylindium (C 18 h 15 In), triphenylpyridine indium (C 23 h 20 InN), p-tolyl indium (C 21 h 21ln) etc.; Gallium-containing organic precursors include but are not limited to: dimethylgallium fluoride (C 2 h 6 FGa), trimethylgallium (C 3 h 9 Ga), triethylgallium (C 6 h 15 Ga), tripropylgallium (C 9 h 21 Ga), triiso...

Embodiment 3

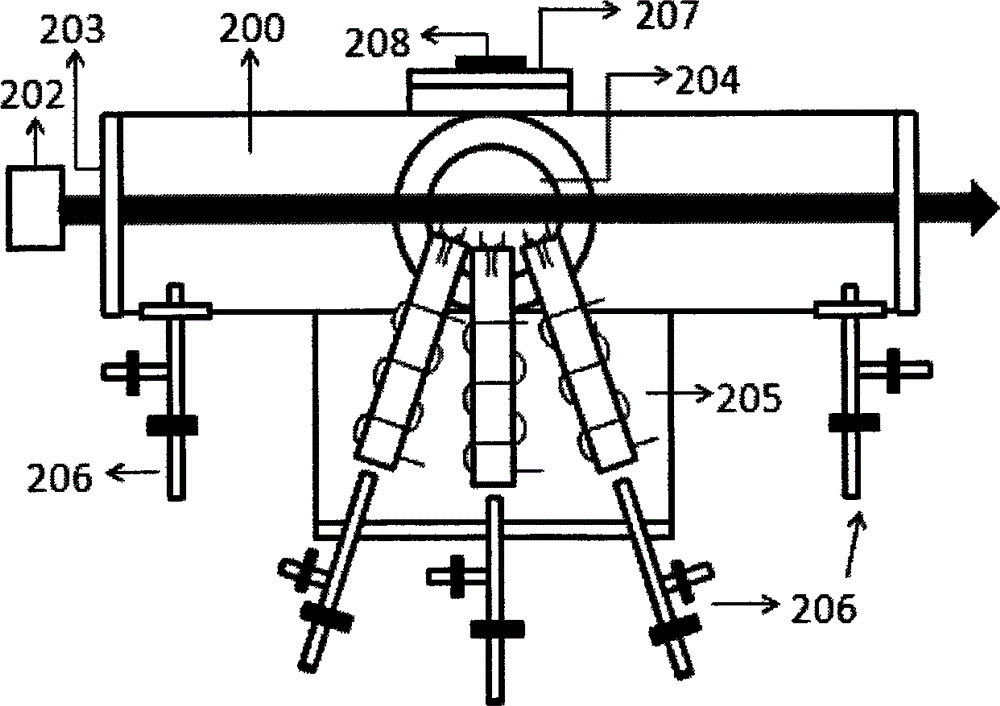

[0039] Same as Example 2, but the substrate is made of flexible stainless steel. The device operates as Figure 4a , Figure 4b shown.

[0040] Figure 4a , 4b are schematic diagrams of the equipment for depositing thin films on flexible roll-to-roll substrates, respectively, Figure 4a is the front view, Figure 4b It is a left view, and the cavity structure and substrate heating device are omitted in the figure. The activated organic precursor gas ejected from the plasma generator 303 is cracked under the laser heating effect generated by the laser 302, and the obtained copper, indium, gallium, and selenium atoms interact to form a copper indium gallium selenide compound, which is deposited on the flexible substrate 301 on. The flexible substrate 301 is unwound by the unwinding device 306 , and the film-deposited part 304 is rewound by the unwinding device 307 . The region where the laser-heated precursor gas reacts and the particles are deposited on the substrate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com