High-voltage plasma membrane switch and manufacture method thereof

A plasma and membrane switch technology, which is applied in the field of pyrotechnics, can solve the problems of low trigger energy, high trigger energy, and short response time, and achieve the effects of low trigger energy, reduced trigger energy, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained in detail below in conjunction with specific embodiments and accompanying drawings.

[0024] The preparation process of the high-voltage plasma membrane switch of the present invention is as follows:

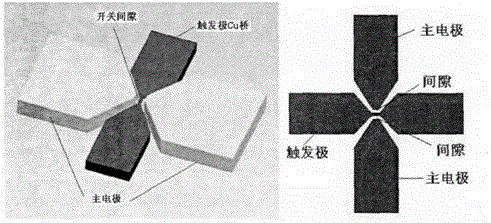

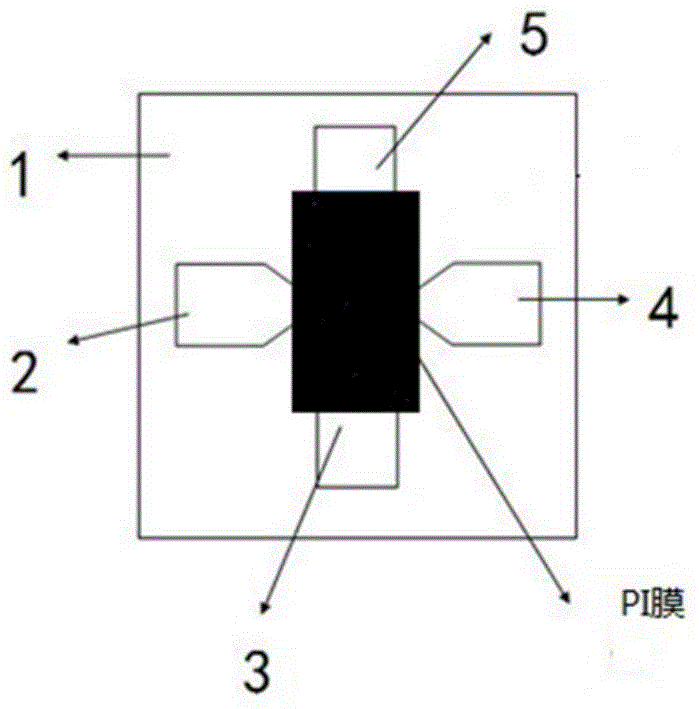

[0025] (1) Select a high-purity alumina substrate with a radius of 3 inches or 2 inches, clean it successively with acetone, alcohol, deionized water, and ultrasonic waves, and then use screen printing technology to deposit 4 on the surface of the substrate according to the designed pattern. Silver electrode, the thickness of the electrode is 2-4um, and its graphic distribution is as follows Figure 4 As shown, the electrodes 2 and 4 are used as trigger electrodes, the distance between the two trigger electrodes is 0.5mm, and the electrodes 3 and 5 are used as the main electrodes, and the distance between the two main electrodes is 1.3mm;

[0026] (2) Overlay the substrate on which the electrodes have been deposited and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com