Method for preparing monodisperse stannic oxide nanocrystalline particles

A technology of tin dioxide and nanocrystals, which is applied in the fields of nanomaterial preparation, catalysts, gas sensors and electrode materials, can solve the problems of high energy consumption and complicated preparation process, and achieve large specific surface area, simple preparation process, and easy large-scale The effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

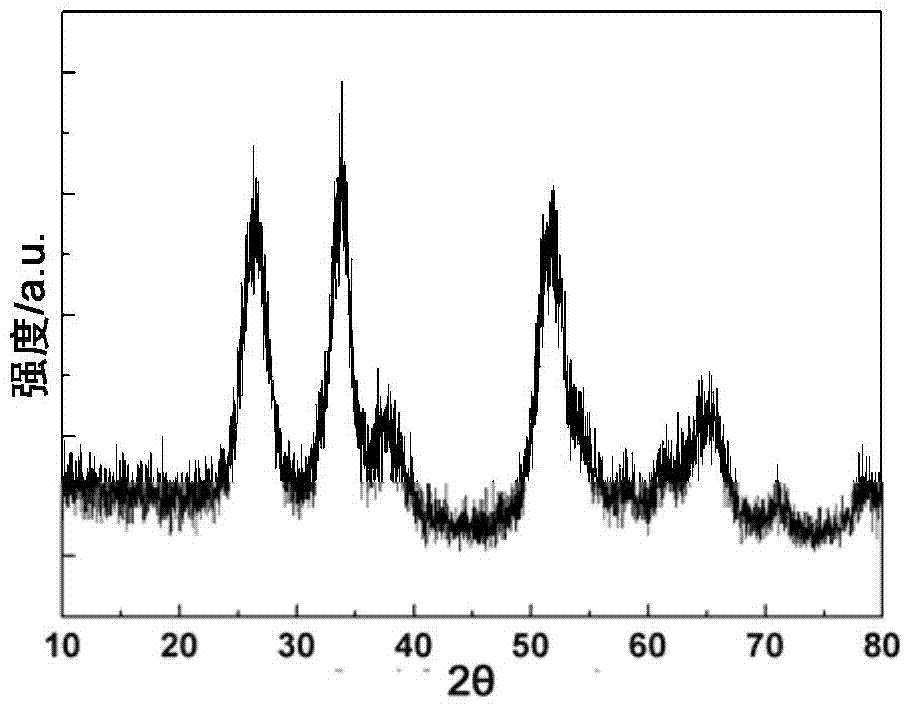

Embodiment 1

[0027] In this example, SnCl 4 ·5H 2 O is the raw material, benzimidazole is used as the mineralizer, and the mixed solution of water and ethanol is used as the solvent, and reacted at 180°C for 20 hours to obtain monodisperse, large specific surface area, and high-purity tin dioxide nanocrystalline particles. The specific process steps include:

[0028] (1) Mix 20mL deionized water and 20mL ethanol evenly as a solvent, and 0.35g SnCl 4 ·5H 2 O and 0.1g benzimidazole are also dissolved in a solvent to obtain a mixed solution;

[0029](2) Transfer the obtained mixed solution to a 50mL polytetrafluoroethylene-lined stainless steel reaction kettle, and react at 180°C for 20h to obtain a white sample;

[0030] (3) Wash the obtained white sample with deionized water and ethanol in sequence, and then dry it in air at 100°C to obtain monodisperse SnO with an average diameter of about 3.4nm. 2 Spherical nanocrystalline particles with a specific surface area of 223.6m 2 g -1 ,...

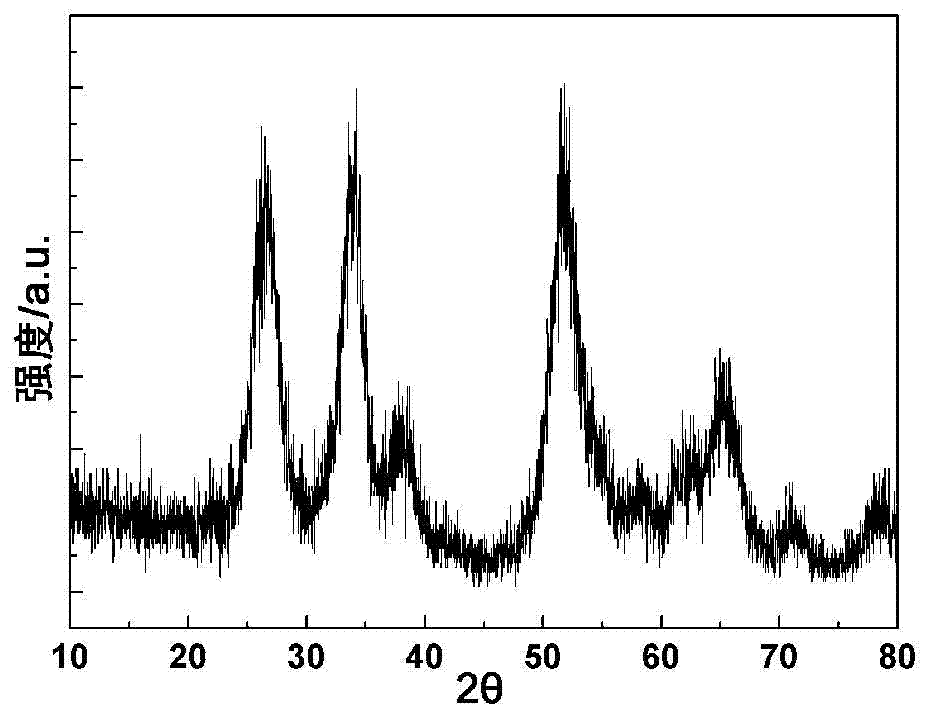

Embodiment 2

[0032] In this example, the amount of benzimidazole used is 0.3 g, and other experimental conditions are the same as in Example 1, and an ellipsoidal monodisperse SnO 2 Nanocrystalline particles, the average long diameter is 7.4nm, the average short diameter is about 4.8nm, and the specific surface area is 181.2m 2 g -1 , the pore size is 6.4nm.

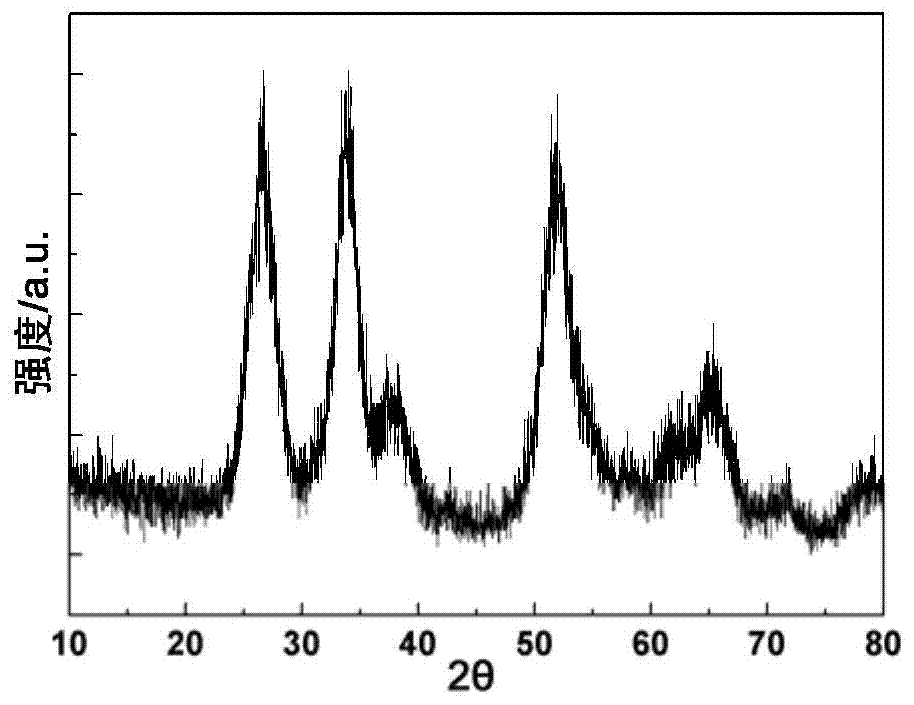

Embodiment 3

[0034] In this embodiment, the amount of benzimidazole used is 0.6g, and other experimental conditions are the same as in Example 1. The prepared SnO 2 Aggregation of nanocrystalline particles occurs, the particles are spherical, the average diameter is about 5.2nm, and the specific surface area is 109.7m 2 g -1 , Compared with Examples 1 and 2, the specific surface area obviously decreases; the pore diameter is 4.3nm.

[0035] This example regulates the amount of SnO by adjusting the amount of mineralizer benzimidazole 2 The particle size and morphology of nanocrystals, under the control of benzimidazole, the prepared SnO 2 Nanoparticles have the advantages of uniform size, good monodispersity, high crystallinity, and large relative area, and have potential applications in the fields of catalysts, gas sensors, and electrode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com