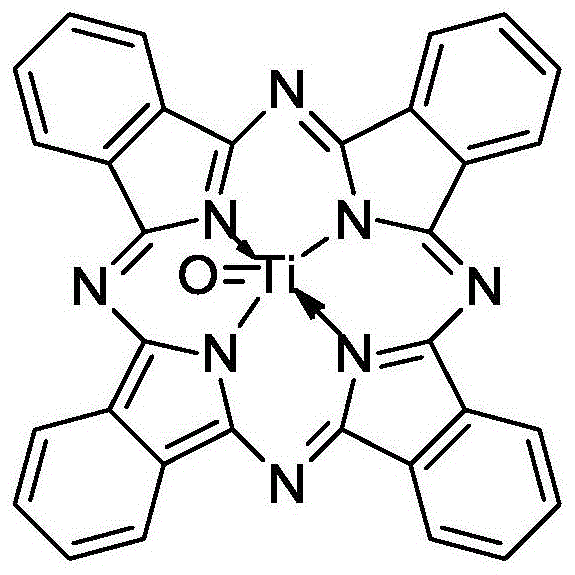

Preparation method of polymorphic photosensitive tiopc nanoparticles and its application in organic photoconductors

A nanoparticle, photosensitive technology, applied in nanotechnology, organic chemistry, titanium organic compounds, etc., to achieve the effect of simplifying the washing process, small particle size, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] 1. The method for preparing α-TiOPc nanoparticles provided by the invention comprises the steps in sequence:

[0034] 1) Dissolve a certain mass of crude titanyl phthalocyanine in concentrated sulfuric acid with a mass fraction of 98% at -5°C to 5°C, and then drop it into the continuously stirring -15°C at a rate of 1mL / min to 60mL / min In transition solvent at ~5°C;

[0035] 2) After the dropwise addition, adjust the heat preservation temperature to -15~5℃, and continue to stir for 1~72 hours to obtain a blue emulsion, add low-carbon alcohol to it, let it stand, wait for layers, separate the liquid, and use deionized Water is repeatedly extracted until the water phase is neutral;

[0036] 3) Separate the organic phase, add a precipitant to it, and let it stand to make the TiOPc nanoparticles settle;

[0037] 4) Pour off the supernatant, filter, wash the filter cake with methanol, then beat with deionized water, and freeze-dry to obtain α-TiOPc nanoparticle powder;

...

Embodiment 1

[0042] Embodiment 1: prepare α-TiOPc nanoparticles

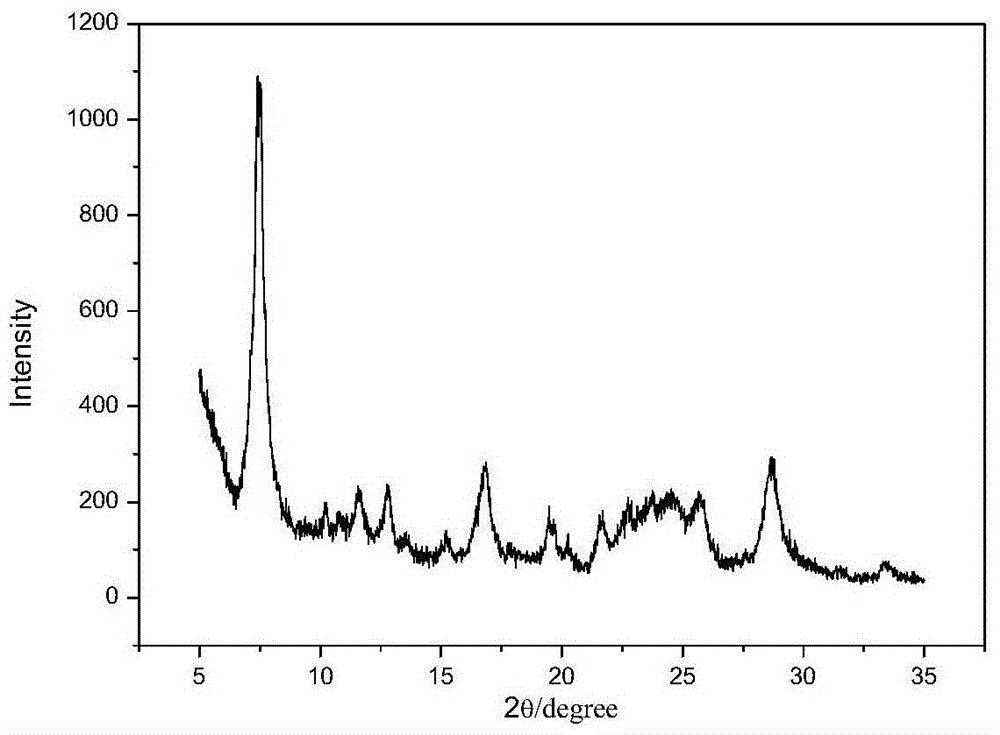

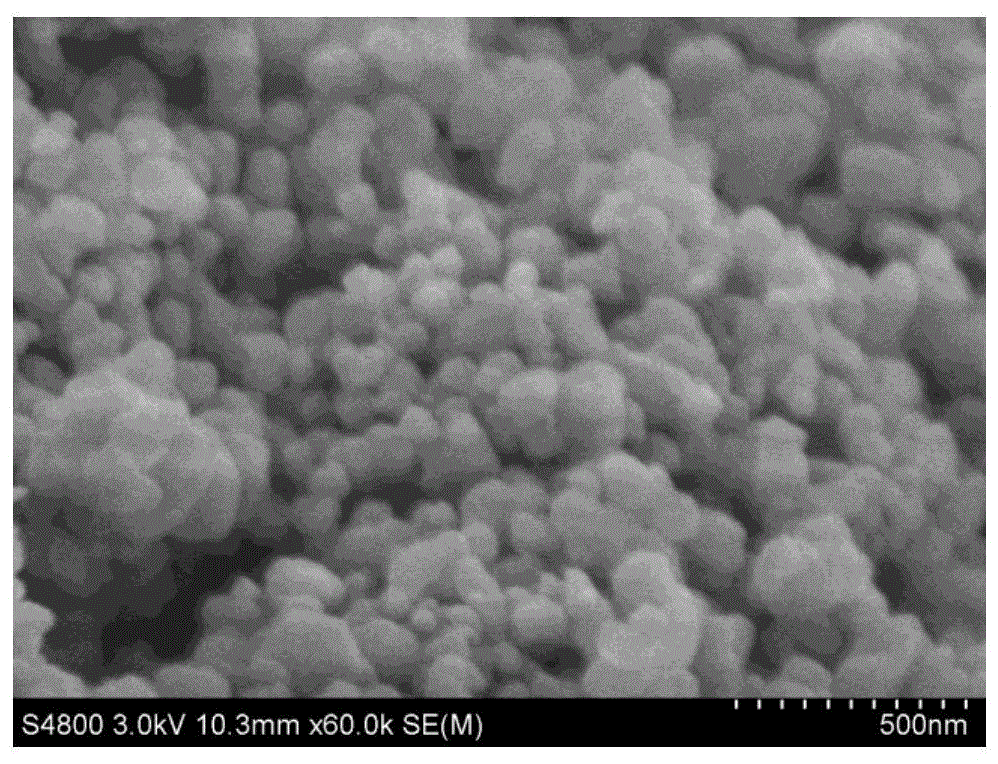

[0043]Dissolve 1g of crude titanyl phthalocyanine in 60mL of concentrated sulfuric acid with a mass fraction of 98%, and then add it dropwise at a rate of 1mL / min to 10mL of butanol, 20mL of water and 30mL of o-dichlorobenzene under constant stirring at -15°C In the transformation solvent formed, after the dropwise addition is completed, continue to maintain the temperature of the transformation system at -15°C, continue to stir for 1 hour, extract the mixed solution with water, extract all the phthalocyanine titanium into the o-dichlorobenzene phase, and separate the liquids to obtain the o- Dichlorobenzene phase, 100mL ethanol was added thereinto, the TiOPc nanoparticles were settled, filtered, and the filter cake was beaten with water, and vacuum freeze-dried to obtain blue powder particles, which were analyzed by X-ray powder diffraction ( figure 2 ) proves that the crystal form is α-TiOPc (characteristic diffraction an...

Embodiment 2

[0044] Embodiment 2: Preparation of α-TiOPc nanoparticles

[0045] Dissolve 1 g of crude titanyl phthalocyanine in 30 mL of concentrated sulfuric acid with a mass fraction of 98%, and then add it dropwise at a rate of 60 mL / min to 1000 mL of ethanol, 1000 mL of water, 500 mL of o-dichlorobenzene and 500 mL of In the transformation solvent composed of dichloromethane, after the dropwise addition is completed, continue to maintain the temperature of the transformation system at 5°C, continue to stir for 72 hours, extract the mixed solution with water, extract all the phthalocyanine titanium into the organic phase, and separate the liquids to obtain the organic phase , add 1000mL butanol to it, make the TiOPc nanoparticles settle, filter, beat the filter cake with water, and freeze-dry in vacuum to get blue powder particles. X-ray powder diffraction analysis proves that the crystal form is α-TiOPc (characteristic diffraction angle 2θ is 7.5°, 25.3°, 28.6°), and the particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com