Hot mix asphalt recycling agent as well as preparation method and application thereof

A kind of asphalt rejuvenator and hot mixing technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of poor compatibility, slow permeation and diffusion, etc., and achieve the goal of enhancing compatibility, scientific formula, and promoting comprehensive recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

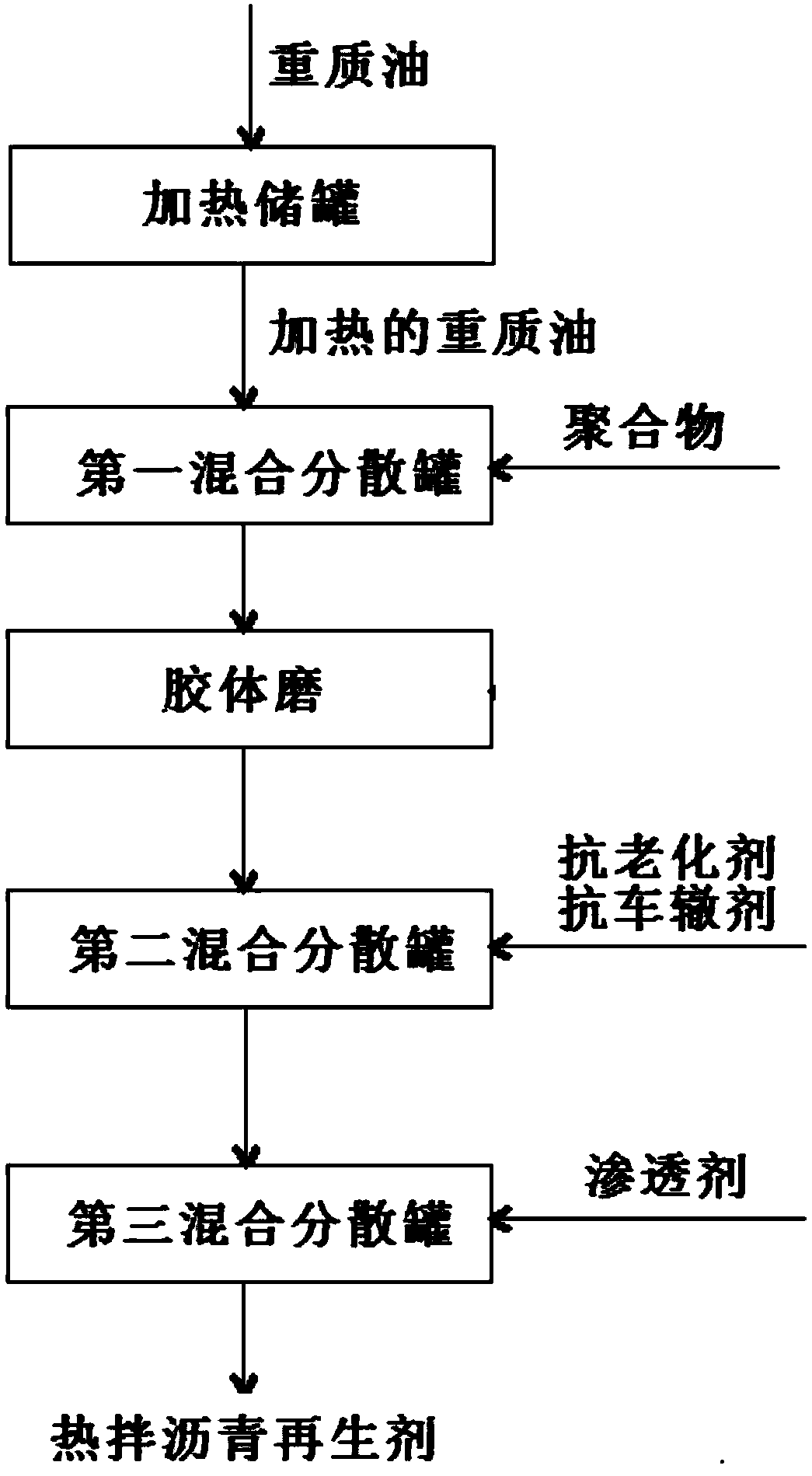

[0044] The invention provides a preparation method of the hot-mix asphalt rejuvenator, comprising the following steps: subjecting heavy oil and polymer to high-speed shearing at 120-180°C; mixing and dispersing with anti-aging agent and anti-rutting agent, Then cool to 70-90°C; then add penetrating agent and fully stir and mix to obtain a hot mix asphalt rejuvenator. After cooling to 70-90°C, adding penetrating agent can prevent high temperature decomposition of penetrating agent.

[0045] When the aromatic content in the heavy oil is less than 85wt%, in order to increase the aromatic content in the heavy oil, the raw oil needs to be pretreated: use furfural extraction process to concentrate and separate the aromatic components, and obtain the aromatic-rich components for regeneration The heavy oil component of the agent. In order to increase the aromatic content in heavy oil, the pretreatment of raw oil can also use propane or butane supercritical extraction.

[0046] The p...

Embodiment 1

[0049] figure 1 It is a flow chart of the production process of the hot-mix asphalt rejuvenator of the present invention.

[0050] This example provides a hot-mix asphalt rejuvenator for hot-mix regeneration of asphalt shavings, which includes the following components by weight:

[0051] 70.0 parts of heavy oil;

[0052] Polymer 20.0 parts;

[0053] Penetrant 1.0 parts;

[0054] 1.5 parts of anti-aging agent;

[0055] Anti-rutting agent 2.0 parts.

[0056] The content of aromatic components in the heavy oil is greater than 90 wt%, and the average molecular weight Mn is between 300-350. The polymer is a star SBS (Styrenic Thermoplastic Elastomer). The penetrating agent is alkylphenol polyoxyethylene ether. The aging agent is sodium hydroxide. The anti-rutting agent PR anti-rutting agent.

[0057] Such asfigure 1 As shown, the preparation method of the hot-mix asphalt rejuvenator comprises the following steps: the heavy oil is heated in a heating storage tank; the heate...

Embodiment 2

[0060] This example provides a hot-mix asphalt rejuvenator for hot-mix regeneration of asphalt shavings, which includes the following components by weight:

[0061] 75.0 parts of heavy oil;

[0062] Polymer 15.0 parts;

[0063] 1.2 parts of penetrant;

[0064] Anti-aging agent 18 parts;

[0065] Anti-rutting agent 1.8 parts.

[0066] The content of aromatic components in the heavy oil is greater than 85 wt%, and the average molecular weight Mn is between 280-400. The polymer is linear SBS (Styrenic Thermoplastic Elastomer). The penetrating agent is a polyether nonionic surfactant. In this embodiment, the aging agent adopts tallow propylene diamine. The anti-rutting agent PR anti-rutting agent.

[0067] The preparation method of the hot-mix asphalt rejuvenator includes the following steps: high-speed shearing of heavy oil and polymer at 180°C, mixing and dispersing with anti-aging agent and anti-rutting agent, and then cooling to 70°C; adding infiltration The hot mix as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com