A fermentation production method for aureomycin by utilizing mycoprotein in place of a portion of yeast powder

A technology of cell protein and replacement part, applied in the field of fermentation production of chlortetracycline, can solve the problems of high price and high cost of raw materials, and achieve the effects of reducing cost of raw materials, increasing yield and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

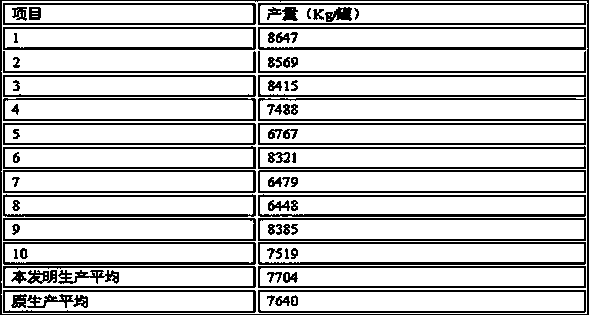

Examples

Embodiment

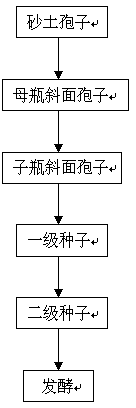

[0017] Embodiment: the fermentation production method of aureomycin of the present invention is to use Streptomyces aureus as the starting bacterial strain, and generates aureomycin through purebred culture and three-stage fermentation. The process, the slanted spore preparation process of the sub-bottle, the first-level seed preparation process, the second-level seed preparation process, and the fermentation preparation process are characterized in that:

[0018] (1) Sand spore preparation process: Soak the river sand in 10% hydrochloric acid and wash it with water, then dry it and pass it through a 60-mesh sieve, soak the soil in water, and pass it through a 80-mesh sieve after drying. Sand and soil are mixed evenly at a ratio of 2:1, and packed in 12×100mm small test tubes, with a filling volume of about 1cm, sealed with gauze cotton plugs, sterilized three times at 121-126°C for 1 hour, and dried for sterility test inspection. Ready for use after sterilisation. Put the is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com