Method for preparing hard magnetic oxide coating on metal base material

A technology of oxide coating and metal substrate, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of magnetic thick film thickness and magnetic properties that cannot be fully satisfied, and achieve the promotion of development and application, Coating dense, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

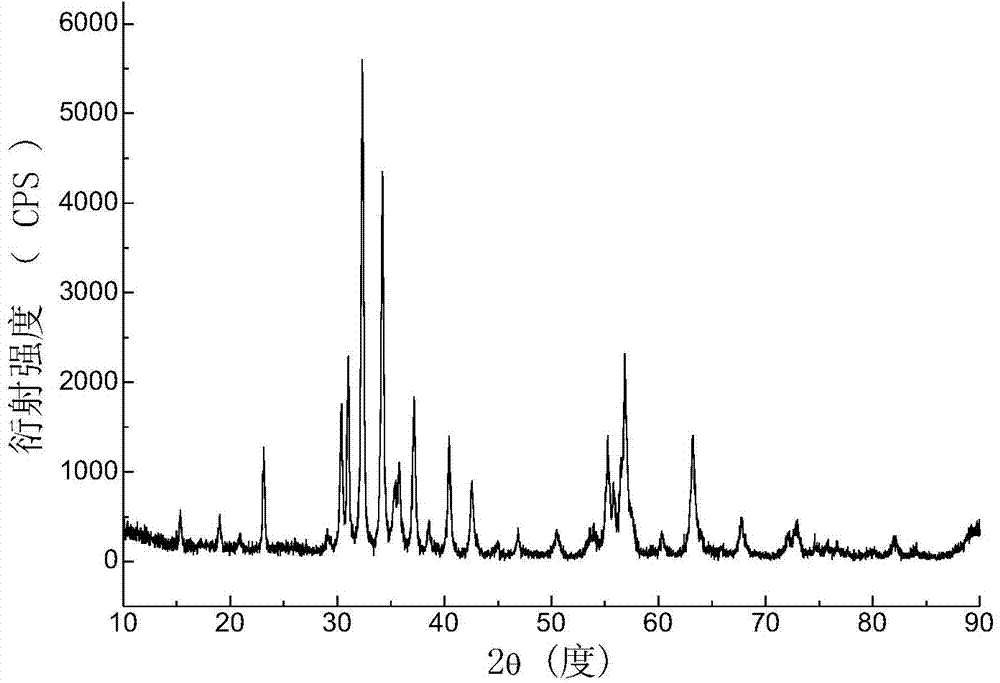

[0034] Preparation of Hard Magnetic SrFe on 20 Steel Substrate 12 o 19 type ferrite coating method.

[0035] The first step, the preparation of powder particles for plasma spraying

[0036] Commercially available raw material SrFe 12 o 19 Type ferrite powder, the powder particles for plasma spraying are prepared by spray granulation method, the above raw material SrFe 12 o 19 Type ferrite powder, solvent water and binder polyvinyl alcohol are fully stirred and mixed to make a slurry. The mass percentage of each component in the slurry is, the original SrFe 12 o 19 The solid content of type ferrite powder is 35%, the binder polyvinyl alcohol is 1%, and the rest is solvent water, and then spray granulation. The process parameters of spray granulation are: air outlet temperature 110°C, air inlet temperature 220°C ℃, feeding speed 35rpm, after spray granulation, the powder material is further sintered, the sintering temperature is 1100℃, the holding time is 2h, and finally ...

Embodiment 2

[0047] Except that the annealing heat treatment temperature of the fourth step in Example 1 is changed to 1100°C, the others are the same as in Example 1, and the prepared SrFe 12 o 19 The magnetic properties of the coating are listed in Table 1.

Embodiment 3

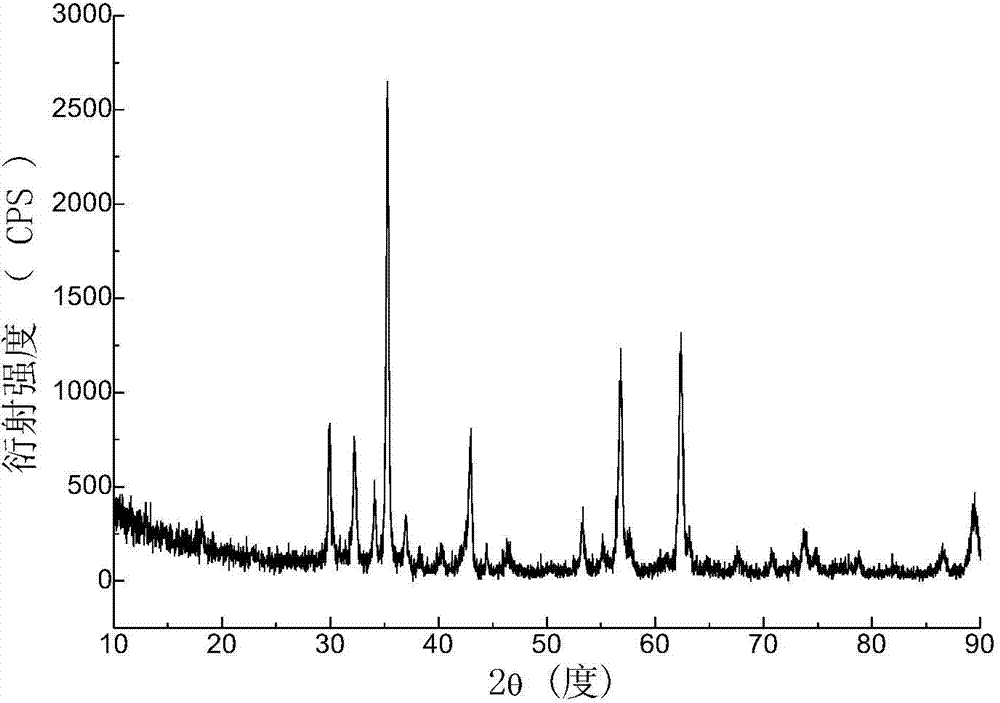

[0049] Except that the annealing heat treatment temperature of the fourth step in Example 1 is changed to 1200°C, the others are the same as in Example 1, and the prepared SrFe 12 o 19 The magnetic properties of the coating are listed in Table 1.

[0050] Comparative Example of Example 3

[0051] In addition, the commercially available SrFe 12 o 19 Type ferrite powder is prepared into a block by the traditional method, that is, first pressed into shape, and then sintered at 1200 ° C for 1 h to obtain SrFe 12 o 19 Block magnets.

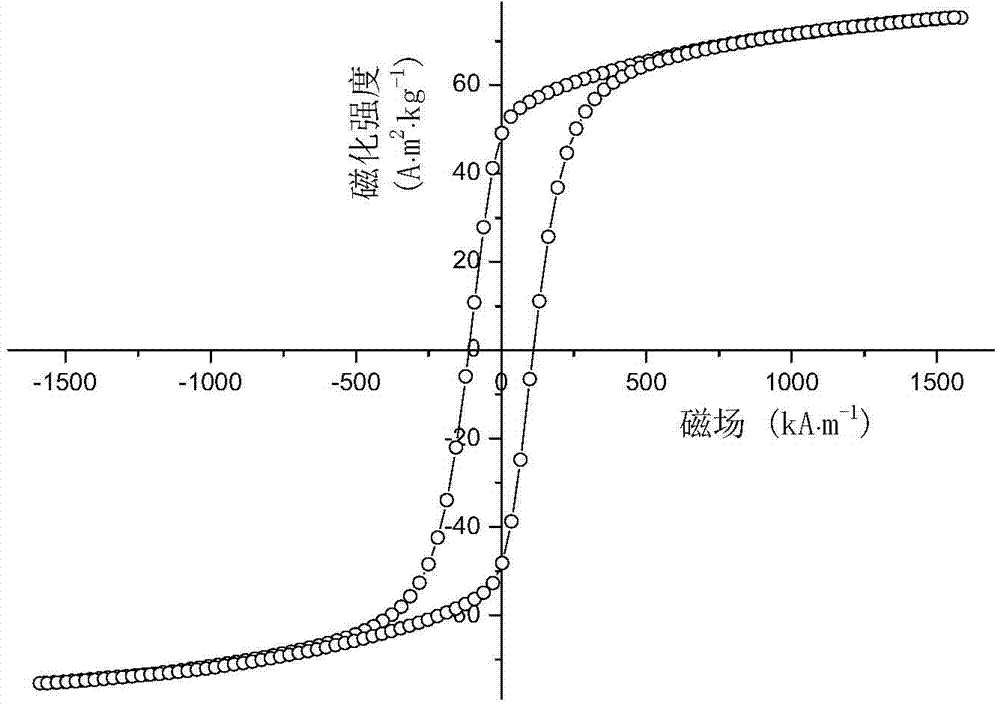

[0052] Figure 4 Commercially available SrFe in Example 3 is given 12 o 19 After the hard magnetic oxide coating is annealed at 1200 °C for 1 h after plasma spraying of the type ferrite powder ( Figure 4 The hysteresis loop of the coated magnet) and the commercially available SrFe in the comparative example of Example 3 12 o 19 Type ferrite powder is sintered at 1200°C for 1 hour by traditional sintering process to obtain a block magnet ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com