Organically soluble photosensitive resin after being cured and preparation method and dissolving method thereof

A photosensitive resin, organic technology, applied in the field of organic soluble photosensitive resin after curing, preparation and dissolution, can solve the problems of electroplating, electroforming, soluble photocurable resin not resistant to aqueous solution, etc., to increase photosensitivity and improve resin resolution The effect of increasing the rate and improving the resin binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

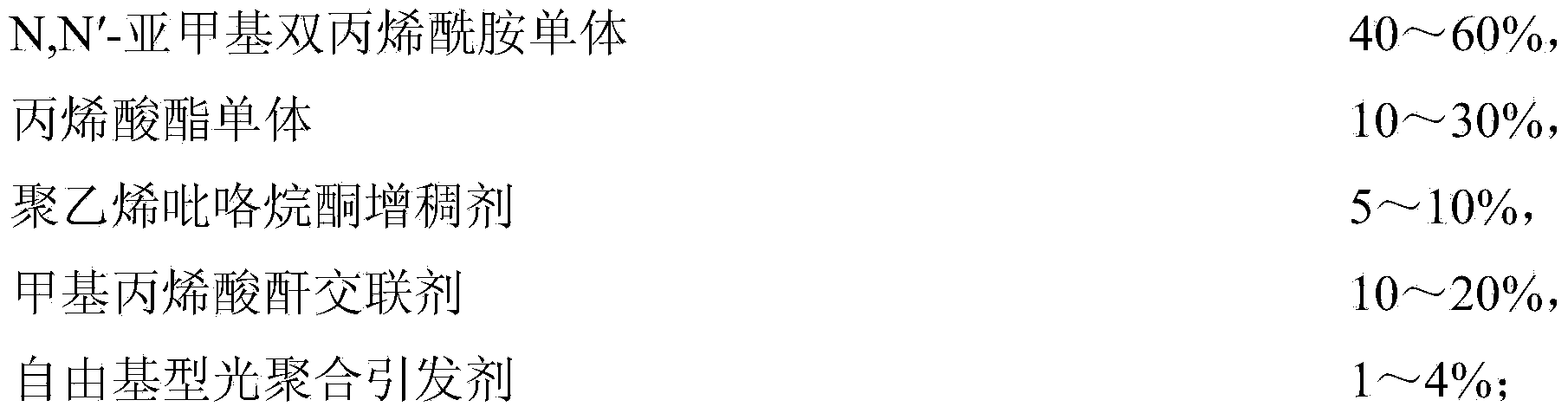

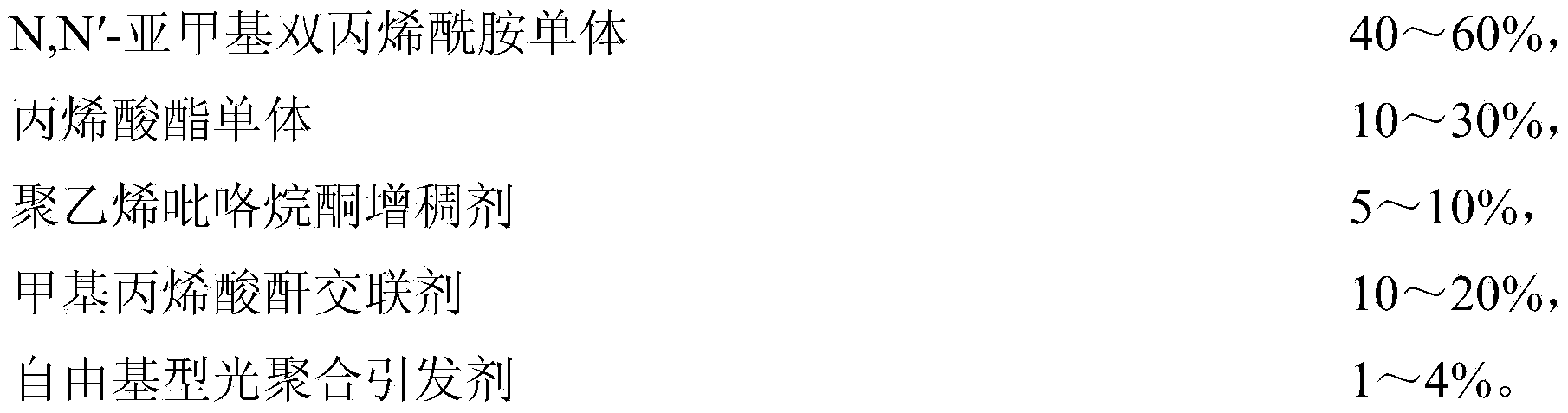

Method used

Image

Examples

Embodiment 1

[0030] 1. Add 10 grams of (2,4,6-trimethylbenzoyl) diphenylphosphine oxide, 100 grams of N,N′-methylenebisacrylamide, hydroxyethyl methacrylate into a 1000 ml plastic beaker 75 grams of esters, 40 grams of methacrylic anhydride.

[0031] 2. Stir and mix the above substances until it becomes a transparent light yellow homogeneous liquid mixture.

[0032] 3. Add 25 grams of polyvinylpyrrolidone to the mixture, put the working head of the homogeneous mixer into the beaker, and stir homogeneously for 10 minutes to obtain a light yellow uniform liquid with a viscosity of 20 cp, which is the photosensitive resin of the present invention .

[0033] 4. The photosensitive resin was irradiated by a 405 nm wavelength visible light curing box with a power of 500 milliwatts for 10 minutes, and the liquid resin was cured into a solid state. Use CNC milling machine to carry out machining experiments on the cured resin. After curing, the resin can be used for high-precision CNC milling with...

Embodiment 2

[0038] 1. Add 10 grams of (2,4,6-trimethylbenzoyl) diphenylphosphine oxide, 250 grams of N,N′-methylene bisacrylamide, hydroxyethyl methacrylate in a 1000 ml plastic beaker 100 grams of ester, 100 grams of methacrylic anhydride.

[0039] 2. Stir and mix the above substances until it becomes a transparent light yellow homogeneous liquid mixture.

[0040] 3. Add 40 grams of polyvinylpyrrolidone to the mixture, put the working head of the homogeneous mixer into the beaker, and stir homogeneously for 10 minutes to obtain a light yellow uniform liquid with a viscosity of 10 cp, which is the photosensitive resin of the present invention .

[0041] 4. The photosensitive resin was irradiated by a 405 nm wavelength visible light curing box with a power of 500 milliwatts for 10 minutes, and the liquid resin was cured into a solid state. Use CNC milling machine to carry out machining experiments on the cured resin. After curing, the resin can be used for high-precision CNC milling with...

Embodiment 3

[0046] 1. Add 10 grams of phenylbis(2,4,6-trimethylbenzoyl) phosphine oxide, 600 grams of N,N′-methylene bisacrylamide, hydroxyethyl methacrylate into a 1000 ml plastic beaker 100 grams of ester, 200 grams of methacrylic anhydride.

[0047] 2. Stir and mix the above substances until it becomes a transparent light yellow homogeneous liquid mixture.

[0048] 3. Add 90 grams of polyvinylpyrrolidone to the mixture, put the working head of the homogeneous mixer into the beaker, and stir homogeneously for 10 minutes to obtain a light yellow uniform liquid with a viscosity of 10 cp, which is the photosensitive resin of the present invention .

[0049] 4. The photosensitive resin was irradiated by a 405 nm wavelength visible light curing box with a power of 500 milliwatts for 10 minutes, and the liquid resin was cured into a solid state. Use CNC milling machine to carry out machining experiments on the cured resin. After curing, the resin can be used for high-precision CNC milling w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com