Paenibacillus polymyxa and difenoconazole compound fungicide and application thereof

A technology for compounding fungicides and Paenibacillus polymyxa, which is applied in the direction of fungicides, applications, biocides, etc., can solve the problem of not finding Paenibacillus polymyxa, etc., to delay the emergence of bacterial resistance, and the environment is pollution-free and good The effect of antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

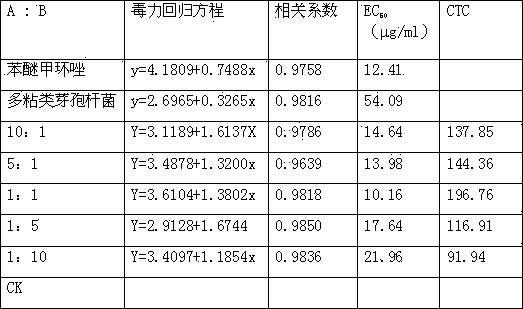

Method used

Image

Examples

Embodiment 1

[0042] Example 1 : 5% difenoconazole + 2.5*10 7 For the preparation of cfu / ml Paenibacillus polymyxa wettable powder, the distribution ratio of each component is:

[0043] The mass ratio of 95% difenoconazole technical substance is 5.26%,

[0044] The concentration of Paenibacillus polymyxa is 10*10 7 cfu / ml bacterial solution 25%,

[0045] Wetting agent: sodium dodecylbenzenesulfonate is 5% by mass,

[0046] Dispersant: sodium lignosulfonate is 5% by mass,

[0047] Filler: diatomaceous earth is 59.74%.

[0048] Mix the Paenibacillus polymyxa fermentation broth with a certain amount of crushed diatomaceous earth, fully dry the mixture and difenoconazole original drug, sodium dodecylbenzenesulfonate, sodium lignosulfonate, etc., cool and mix , Airflow crushing and fine grinding can be the product.

Embodiment 2

[0049] Example 2 : 3% Difenoconazole + 2*10 7 For the preparation of cfu / ml Paenibacillus polymyxa granules, the distribution ratio of each component is:

[0050] The mass ratio of 95% difenoconazole technical substance is 3.16%,

[0051] The concentration of Paenibacillus polymyxa is 10*10 7 cfu / ml bacteria powder 20%,

[0052] Wetting and dispersing agent: sodium dodecylbenzenesulfonate is 1% by mass,

[0053] Binder: polyvinyl acetate is 1% by mass,

[0054] Auxiliary disintegration agent: urea is 2% mass ratio,

[0055] Adsorbent: white carbon black 2% mass ratio,

[0056] Stabilizer: butyl glycidyl ether is 7% by mass,

[0057] Carrier: 63.84% activated clay.

[0058] Fully mix the original drug, bacterial liquid, sodium dodecylbenzenesulfonate, polyvinyl acetate, urea, white carbon black, butyl glycidyl ether, and activated clay, ultrafinely pulverize, granulate, dry, and sieve. Grading is the product.

Embodiment 3

[0059] Example 3 : 8% Difenoconazole + 1*10 7 The preparation of cfu / ml Paenibacillus polymyxa water-dispersible granules, the distribution ratio of each component is:

[0060] The mass ratio of 95% difenoconazole technical substance is 8.42%,

[0061] The concentration of Paenibacillus polymyxa is 10*10 7 cfu / ml bacterial powder 10%,

[0062] Wetting agent: sodium lignosulfonate is 8% by mass,

[0063] Binder: polyvinyl acetate is 9% by mass,

[0064] Auxiliary disintegrant: urea is 15% mass ratio,

[0065] Stabilizer: butyl glycidyl ether is 4% by mass,

[0066] Carrier: activated clay is 45.58%.

[0067] Each component is superfinely pulverized, then granulated, dried, sieved, and classified to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com