Method for preparing magnesium hydroxide and chlorine by coupling magnesium chloride reactive crystallization and electrolysis

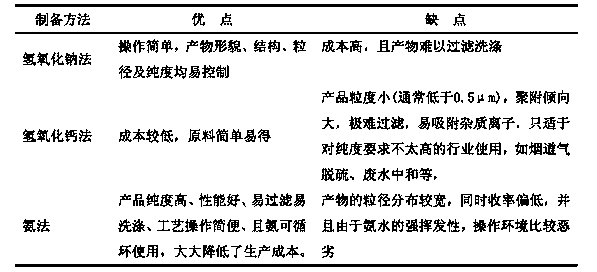

A technology of reaction crystallization and magnesium hydroxide, which is applied in the direction of magnesium hydroxide, electrolytic process, electrolytic components, etc., can solve the problems of difficult filtration and low purity of magnesium hydroxide, and achieve easy filtration, solution of chlor-alkali balance, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] First, prepare 2.5mol / l magnesium chloride magnesium-based solution, 5.0mol / l sodium hydroxide lye, 0.5mol / l rubidium chloride solution, and preheat to 60°C for use. Take 90ml rubidium chloride and add it to the reactor as the bottom material. At 60°C and the stirring rate of 1.5m / s, add the lye and the magnesium-based solution to the reactor at the feed rate of 1ml / min at the same time. The reaction is over After suction filtration. The filter cake was washed three times with deionized water, and finally dried in hot air at 120°C for 8 hours. After the filtrate was simply refined by chelating resin, a certain amount of sodium chloride was added to adjust the concentration, at a voltage of 3.2 to 3.7 volts, 94%~ At a current efficiency of 99%, sodium hydroxide and chlorine are prepared by electrolysis using a thin film method. The prepared high purity magnesium hydroxide has a purity of 99.8%, an average particle size of 11.84 μm, and a water content of the filter cake ...

Embodiment 2

[0041] Prepare 3.0 mol / l magnesium chloride aqueous solution (magnesium-based solution), 6.0 mol / l sodium hydroxide aqueous solution (lye), 1.0 mol / l potassium chloride aqueous solution, and preheat to 80°C for use. Take 90ml of potassium chloride aqueous solution and add it to the reactor as the bottom material. At 80°C and at a stirring rate of 1.5m / s, add the lye and magnesium-based solution to the reactor at a feed rate of 1.5ml / min. After the reaction, suction filtration is performed. The filter cake was stirred and washed with deionized water for three times, and finally dried in hot air at 120°C for 8 hours. After the filtrate was simply refined by chelating resin, a certain amount of sodium chloride was added to adjust the concentration, at a voltage of 3.4 to 3.7 volts. Under the current efficiency of %~99%, the membrane method is used for electrolysis to prepare sodium hydroxide and chlorine. The prepared high purity magnesium hydroxide has a purity of 99.7%, an aver...

Embodiment 3

[0043] Prepare 4.0 mol / l magnesium chloride aqueous solution (magnesium-based solution), 8.0 mol / l sodium hydroxide aqueous solution (lye) and 4.0 mol / l sodium chloride aqueous solution, and preheat to 70°C for use. Take 50ml of sodium chloride aqueous solution and add it to the reactor as the bottom material. At 70℃, the stirring rate is 1.2m / s, the lye and magnesium-based solution are added in continuous operation, and the material is continuously discharged. The residence time is 50min. After the system is stable, collect and filter the material liquid. The filter cake was stirred and washed with deionized water for three times, and finally dried at 120°C in hot air for 8 hours. After simple purification, a certain amount of sodium chloride was added to adjust the concentration of the filtrate. At a voltage of 3.4 to 3.7 volts, 94% to 99% Under current efficiency, the membrane method is used for electrolysis to prepare sodium hydroxide and chlorine. The prepared high-purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com