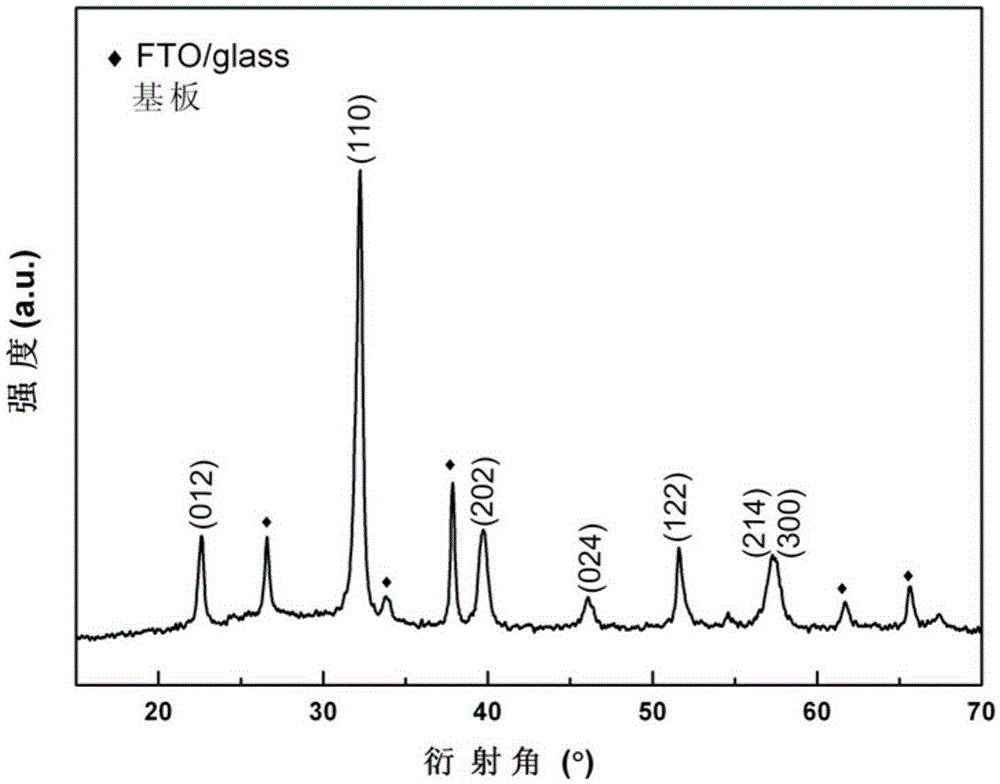

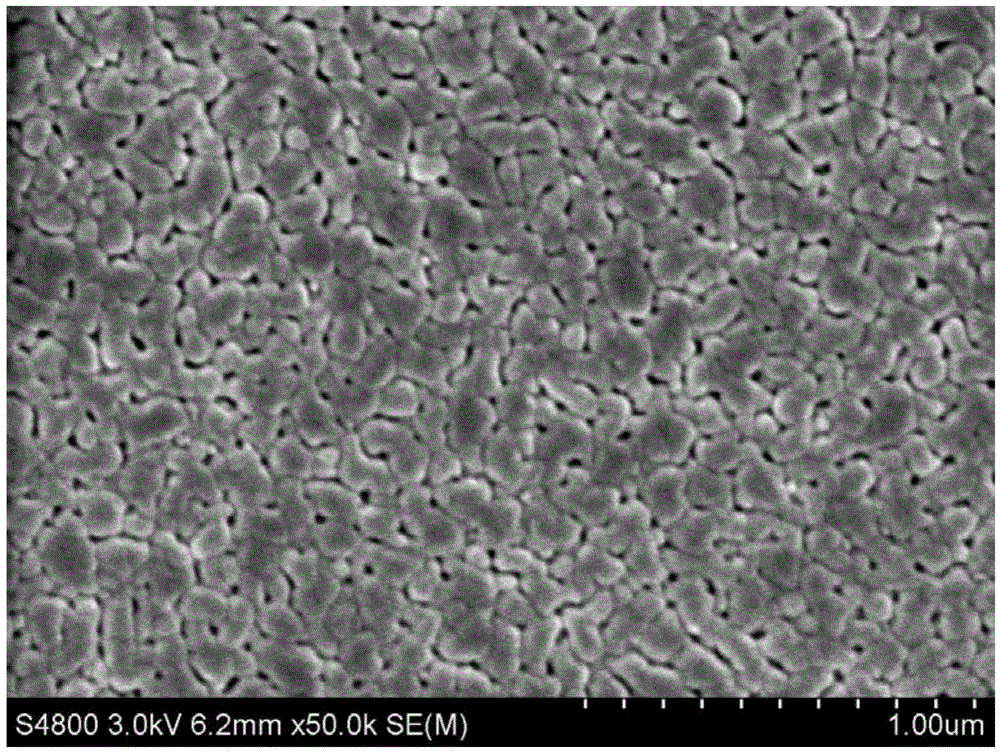

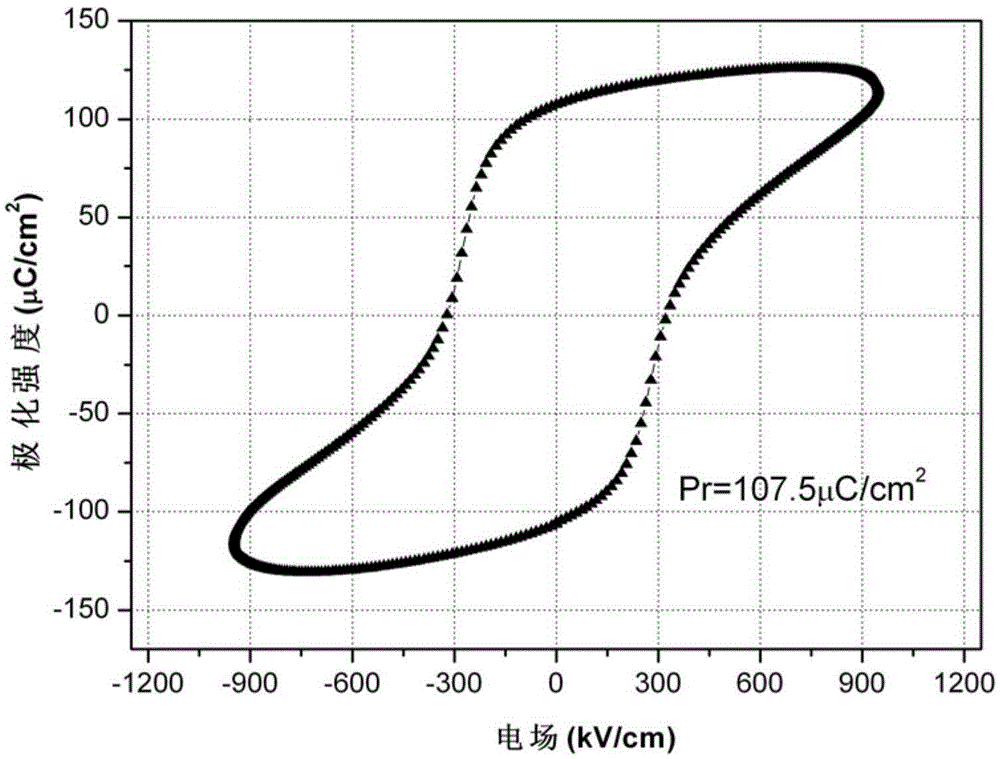

A kind of bifeo3 thin film with ternary co-doping of tb, cr and mn with high remnant polarization and its preparation method

A polarization, high residual technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve the problems of low resistivity, limited application, low dielectric constant, etc., to improve ferroelectric and ferromagnetic properties , The effect of improving multiferroic properties and enhancing insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) The Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 ·9H 2 O, Tb(NO 3 ) 3 ·6H 2 O, Cr(NO 3 ) 3 ·9H 2 O and C 4 H 6 MnO 4 ·4H 2 O is dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride in a molar ratio of 0.94:0.97:0.11:0.02:0.01, and then stirred for 2h to make it uniform to obtain BiFeO 3 Precursor fluid; Among them, BiFeO 3 The total metal ion concentration in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride in the mixed solution is 3:1;

[0026] 2) The BiFeO 3 The precursor liquid is allowed to stand for 24 hours, and then BiFeO is spin-coated on the FTO / glass substrate 3 The precursor solution prepares a wet film. The wet film is baked at 200°C for 12 minutes to obtain a dry film, and then fast annealed at 550°C for 8 minutes to obtain crystalline BiFeO 3 film.

[0027] 3) BiFeO to be crystalline 3 After the film is cooled, repeat step 2) until the crystalline BiFeO 3 BiFeO film with required thickness...

Embodiment 2

[0029] 1) The Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 ·9H 2 O, Tb(NO 3 ) 3 ·6H 2 O, Cr(NO 3 ) 3 ·9H 2 O and C 4 H 6 MnO 4 ·4H 2 O is dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride in a molar ratio of 0.94:0.96:0.11:0.02:0.02, and then stirred for 2h to homogenize to obtain BiFeO 3 Precursor fluid; Among them, BiFeO 3 The total metal ion concentration in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride in the mixed solution is 3:1;

[0030] 2) The BiFeO 3 The precursor liquid is allowed to stand for 32 hours, and then BiFeO is spin-coated on the FTO / glass substrate 3 The precursor solution prepares a wet film. The wet film is baked at 200°C for 6 minutes to obtain a dry film, and then rapidly annealed at 550°C for 13 minutes to obtain crystalline BiFeO 3 film.

[0031] 3) BiFeO to be crystalline 3 After the film is cooled, repeat step 2) until the crystalline BiFeO 3 The film reaches the required thickn...

Embodiment 3

[0036] 1) The Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 ·9H 2 O, Tb(NO 3 ) 3 ·6H 2 O, Cr(NO 3 ) 3 ·9H 2 O and C 4 H 6 MnO 4 ·4H 2 O is dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride in a molar ratio of 0.94:0.95:0.11:0.02:0.03, and then stirred for 2h to make it uniform to obtain BiFeO 3 Precursor fluid; Among them, BiFeO 3 The total metal ion concentration in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride in the mixed solution is 3:1;

[0037] 2) The BiFeO 3 The precursor liquid is allowed to stand for 28 hours, and then BiFeO is spin-coated on the FTO / glass substrate 3 The precursor solution is used to prepare a wet film. The wet film is baked at 200°C for 8 minutes to obtain a dry film, and then quickly annealed at 550°C for 10 minutes to obtain crystalline BiFeO 3 film.

[0038] 3) BiFeO to be crystalline 3 After the film is cooled, repeat step 2) until the crystalline BiFeO 3 Reach the required th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com