Manufacturing formula of environment-friendly pencil board and technology thereof

A production process and pencil board technology, applied in non-moving pencils, printing, writing utensils and other directions, can solve the problems of reducing processing links, large wood consumption, unfavorable environmental protection, etc., to reduce labor intensity, protect the ecological environment, and reduce processing. link effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

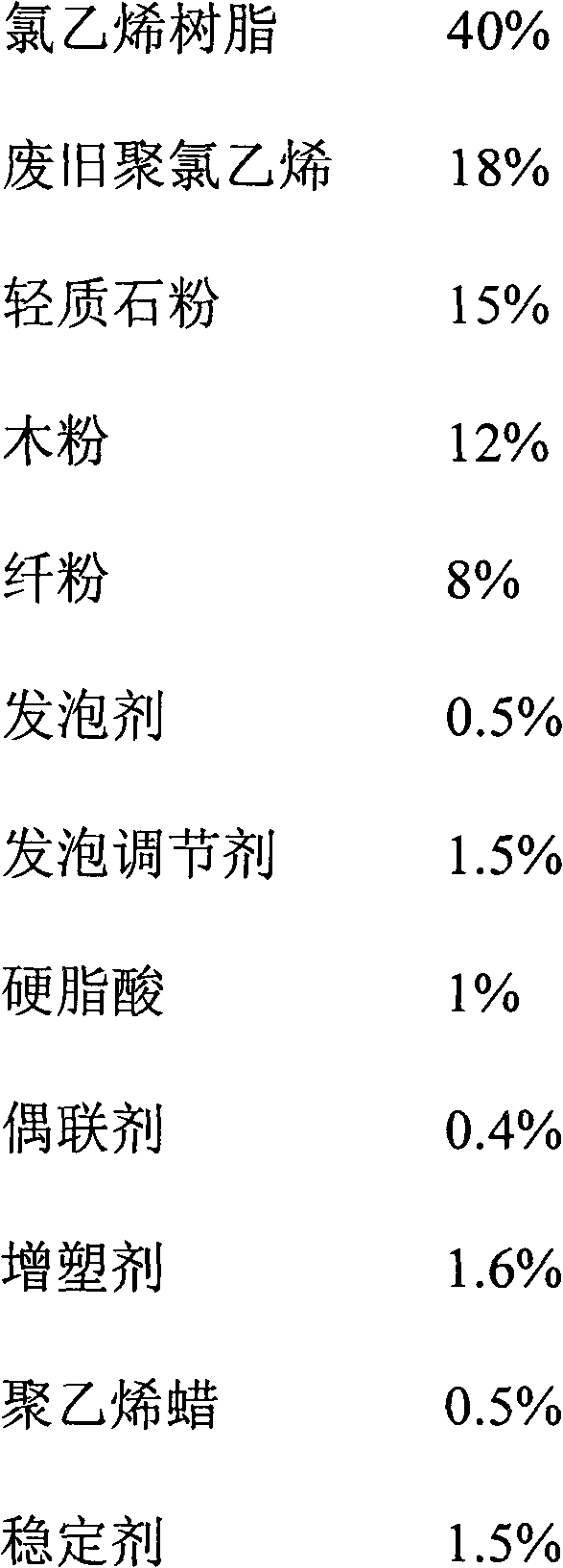

Embodiment 1

[0055] Environmentally friendly pencil board production formula, raw materials include the following ingredients, vinyl chloride resin, waste PVC, light stone powder, wood powder, fiber powder, foaming agent, foaming regulator, stearic acid, coupling agent, plasticizer , polyethylene wax, stabilizer. Vinyl chloride resin, referred to as PVC resin powder, is a collective name for vinyl chloride homopolymer and vinyl chloride copolymer. Waste polyvinyl chloride is waste PVC material. Light stone powder is light calcium carbonate. Wood powder is plant fiber, specifically the powder made from wood, which can be leftover scraps from wood processing in furniture factories, density board factories, and multi-layer board factories; fiber powder is raw materials containing chemical fibers. The foaming agent is an azodicarbonamide molecule: C2H4O2N4, which acts to adjust the density of the product, reduces the processing resistance in the production of pencils, and controls the specif...

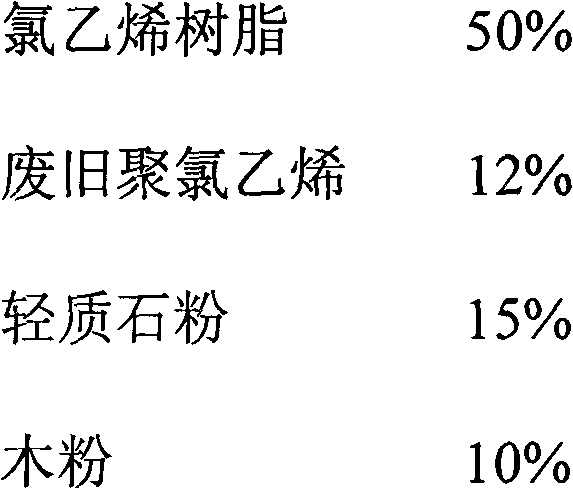

Embodiment 2

[0079] Environmentally friendly pencil board production formula, raw materials include the following ingredients, vinyl chloride resin, waste PVC, light stone powder, wood powder, fiber powder, foaming agent, foaming regulator, stearic acid, coupling agent, plasticizer , polyethylene wax, stabilizer. The specific ingredients are as follows:

[0080] Vinyl chloride resin 40-60%;

[0081] Waste PVC 12-25%;

[0082] Light stone powder 8-20%;

[0083] Wood flour 15-20%;

[0084] Fiber powder 3-15%;

[0085] Foaming agent 0.02-2%;

[0086] Foam regulator 0.08-8%;

[0087] Stearic acid 0.1-2%;

[0088] Coupling agent 0.08-0.4%;

[0089] Plasticizer 1-10%;

[0090] Polyethylene wax 0.2-2%;

[0091] Stabilizer 0.2-4%.

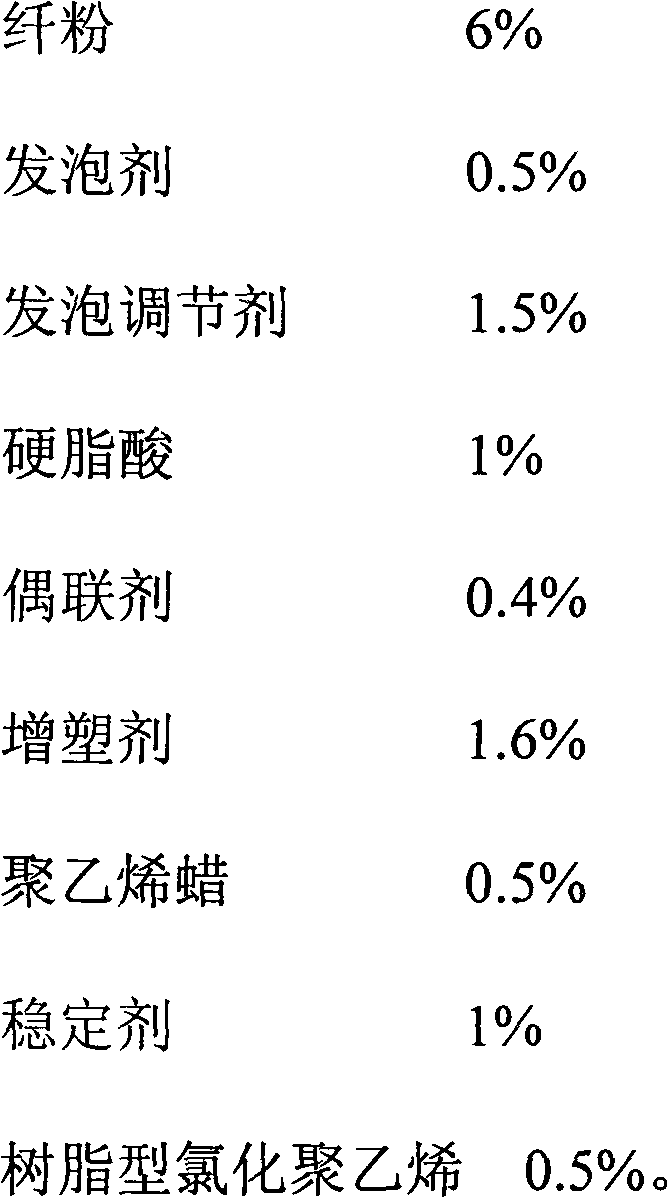

[0092] The specific content of each ingredient is as follows:

[0093]

[0094]

[0095] In the prior art, resin-type chlorinated polyethylene mainly utilizes its advantages such as resistance to heat, oxygen, ozone, aging, and good flame retardancy, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com