Preparation method for nickel-oxide/ reduced-graphene-oxide nanosheet composite materials

A nano-composite material, graphite nano-sheet technology, applied in the field of composite materials, can solve problems such as low specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

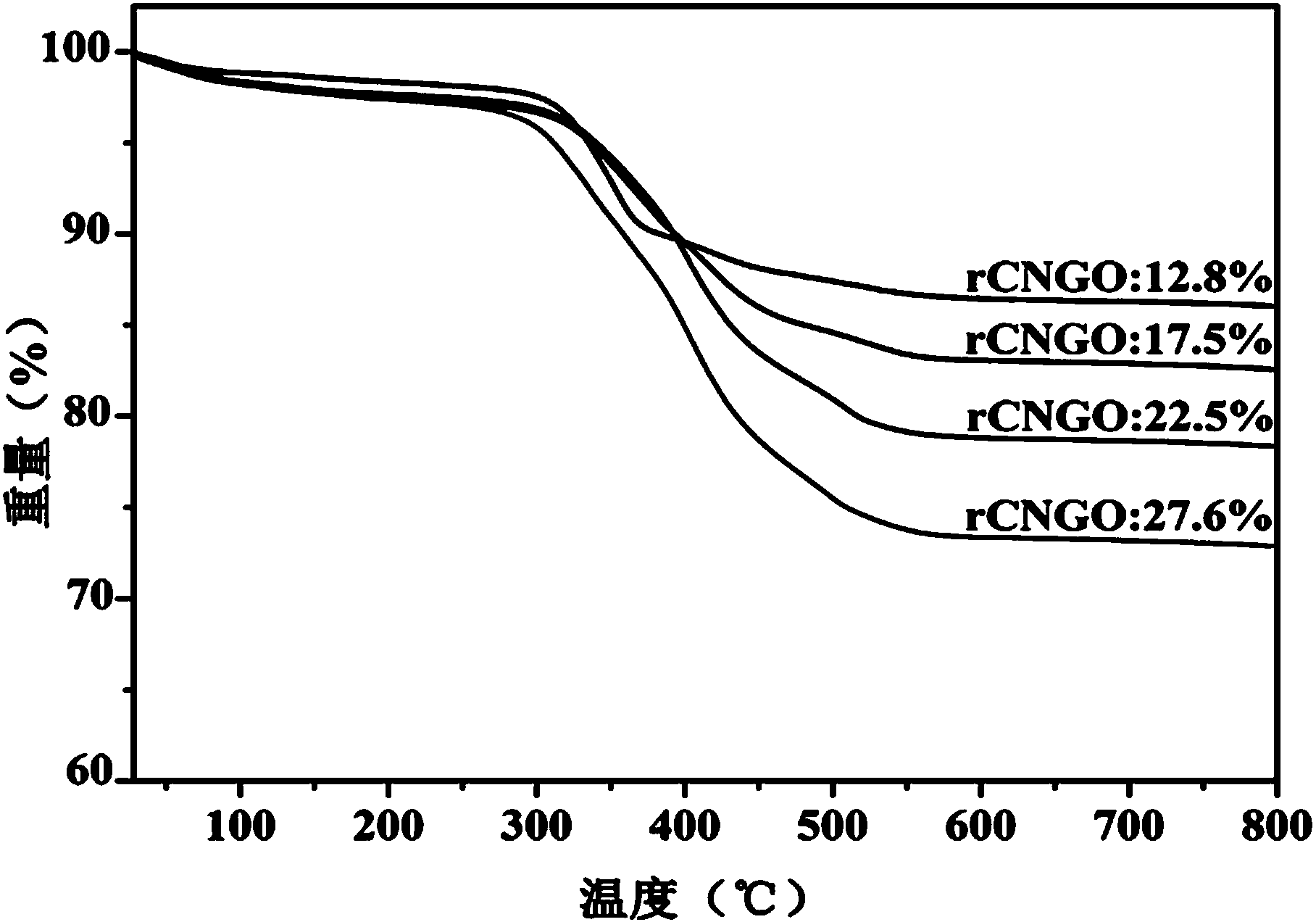

[0028] 1. Preparation of CNGO: Take 46mL of concentrated sulfuric acid with a mass fraction of 98% in a 250mL beaker, and use an ice-water bath to lower the temperature below 4°C. Stir vigorously and add 1g of multi-walled carbon nanotubes at the same time, and wait until it is in an ice-water bath Stir vigorously for 0.5 h; add 0.5 g of sodium nitrate and 4 g of potassium permanganate to the above mixture, and stir vigorously in an ice-water bath for 1 h, then take out the beaker, react vigorously at room temperature for 3 h, then slowly add 92 mL of distilled water dropwise, and wait for Return to room temperature, add 180mL distilled water again, add 15mL 30% H2O after 10min 2 o 2; Stand still for 24 hours, the obtained product is suction filtered, washed with hydrochloric acid solution with a mass fraction of 30%, and then washed with distilled water for 4 to 5 times, then added water / ethanol (7:3v / v), centrifuged at 5000rpm, and the supernatant was taken solution, dilute...

Embodiment 2

[0035] 1, the preparation of CNGO: with embodiment 1.

[0036] 2. Preparation of NiO / rCNGO: 40 mL of CNGO dispersion liquid, other same as Example 1.

[0037] 3. Preparation of capacitance electrodes: same as in Example 1.

[0038] 4. Electrochemical performance test

[0039] (1) Charge and discharge test: the test method is the same as in Example 1. Test results: the specific capacitance value is 928F / g ( Figure 7 c).

[0040] (2) Cycle life test: The test method is the same as in Example 1. Test results: After 3000 cycles, the specific capacitance is still 57% of the initial value.

Embodiment 3

[0042] 1, the preparation of CNGO: with embodiment 1.

[0043] 2. Preparation of NiO / rCNGO: 60 mL of CNGO dispersion liquid, other same as Example 1.

[0044] 3. Preparation of capacitance electrodes: same as in Example 1.

[0045] 4. Electrochemical performance test

[0046] (1) Charge and discharge test: the test method is the same as in Example 1. Test results: the specific capacitance value is 1010F / g ( Figure 7 d).

[0047] (2) Cycle life test: The test method is the same as in Example 1. Test results: After 3000 cycles, the specific capacitance is still 68% of the initial value ( Figure 8 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com