A kind of method that gas-liquid plasma prepares anatase tio2 at low temperature

A plasma and anatase technology, which is applied in chemical instruments and methods, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems such as the large influence of plasma discharge properties, and achieves easy availability of raw materials, simple preparation process, and easy preparation. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

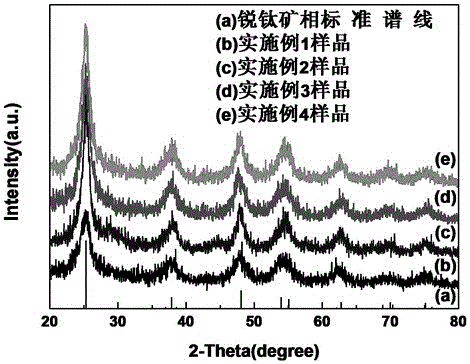

[0019] Add 10 g of titanyl sulfate to 50 ml of deionized water, and stir rapidly to obtain a clear titanyl sulfate aqueous solution; add 6 ml of the above-mentioned titanyl sulfate aqueous solution to the gas-liquid plasma reactor, switch on the plasma power supply, and adjust the discharge voltage to 36 kV. Discharge for 6 minutes, you can get TiO 2 The suspension; then the solid obtained by suction filtration was washed with ethanol three times, washed with water three times, and dried at 100°C for 2 hours. The X-ray diffraction pattern of the sample is shown as the spectral line (b) in the accompanying drawing, indicating that the obtained TiO 2 The crystallinity is low, only a small amount of anatase phase is formed, and the main structure is amorphous.

Embodiment 2

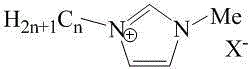

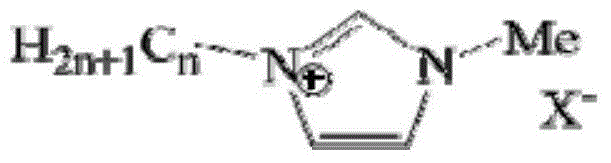

[0021] The difference between embodiment 2 and embodiment 1 is that adding volume ratio in titanyl sulfate aqueous solution is 0.6% [C 4 MIM]BF 4 Ionic liquid, all the other conditions are the same as in Example 1. The X-ray diffraction pattern of the obtained sample is shown as the spectral line (c) in the accompanying drawing, indicating that the obtained TiO 2 It has a single anatase phase structure, and the particle size is about 13nm according to the Scherrer formula.

Embodiment 3

[0023] The difference between embodiment 3 and embodiment 1 is that adding volume ratio in titanyl sulfate aqueous solution is 2.4% [C 4 MIM]HSO 4 Ionic liquid, all the other conditions are the same as in Example 1. The X-ray diffraction pattern of the obtained sample is shown as the spectral line (d) in the accompanying drawing, indicating that the obtained TiO 2 It has a single anatase phase structure, and the particle size is about 8nm according to the Scherrer formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com