Sandalwood cultivation medium and preparation method thereof

A culture medium and technology of sandalwood, applied in the field of sandalwood culture medium and its preparation, can solve the problems of low use efficiency, slow growth, inapplicability, etc., and achieve the effects of reasonable proportion, balanced nutrition, and improved survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

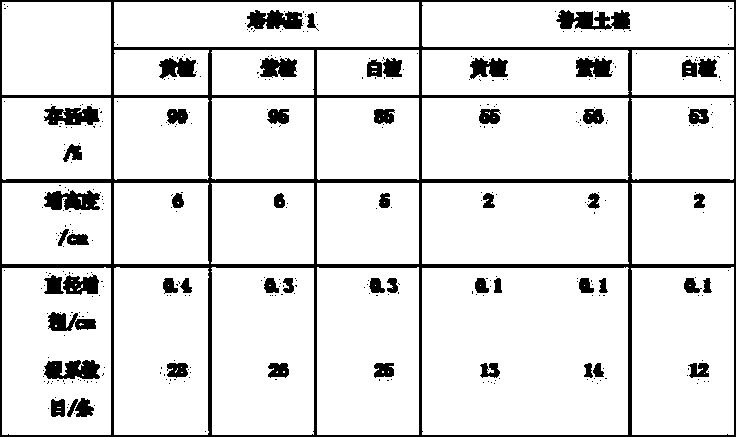

Embodiment 1

[0017] The medium (medium 1) includes the following medium raw materials in parts by weight: 32 parts of peat, 12 parts of straw, 30 parts of river sand, 11 parts of edible mushroom waste, 11 parts of peanut shells, 12 parts of fermented poultry manure, silk reeling 30 parts of waste water, 10 parts of tea bagasse and 5 parts of bagasse. The preparation method of the culture medium comprises the following steps: the first step is to semi-carbonize the straw, peanut shells and bagasse, and pulverize the peat, river sand and tea bagasses, so that the particle size of the raw materials is 10mm; the second step , mix the raw materials prepared in the first step, edible fungus waste residue and fermented poultry manure, and stir evenly to obtain a medium mixture; in the third step, mix the medium mixture with silk reeling wastewater to adjust the carbon content of the medium Nitrogen ratio and carbon-phosphorus ratio; the fourth step is to use 0.5% potassium permanganate aqueous s...

Embodiment 2

[0023] The culture medium includes the following culture medium raw materials in parts by weight: 35 parts of peat, 10 parts of straw, 35 parts of river sand, 12 parts of edible fungus waste residue, 15 parts of peanut shells, 25 parts of fermented poultry manure, 20 parts of silk reeling wastewater, tea 15 parts of bagasse and 4 parts of bagasse. The preparation method of the culture medium comprises the following steps: the first step is to semi-carbonize the straw, peanut shells and bagasse, and pulverize the peat, river sand and tea bagasses, so that the particle size of the raw materials is 20mm; the second step , mix the raw materials prepared in the first step, edible fungus waste residue and fermented poultry manure, and stir evenly to obtain a medium mixture; in the third step, mix the medium mixture with silk reeling wastewater to adjust the carbon content of the medium Nitrogen ratio and carbon-phosphorus ratio; the fourth step is to use 0.5% potassium permanganate...

Embodiment 3

[0025]The culture medium includes the following culture medium raw materials in parts by weight: 34 parts of peat, 11 parts of straw, 32 parts of river sand, 9 parts of edible fungus waste residue, 12 parts of peanut shells, 22 parts of fermented poultry manure, 25 parts of silk reeling wastewater, tea 12 parts of bagasse, 3 parts of bagasse and 5 parts of perlite. The preparation method of the culture medium comprises the following steps: the first step is to semi-carbonize the straw, peanut shells and bagasse, and pulverize the peat, river sand, tea residue and perlite, so that the particle size of the raw materials is 15mm; In the second step, the raw materials prepared in the first step, edible fungus waste residue and fermented poultry manure are mixed and evenly stirred to obtain a medium mixture; in the third step, the medium mixture is mixed with silk reeling wastewater to adjust the culture medium The carbon-to-nitrogen ratio and carbon-phosphorus ratio of the base; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com