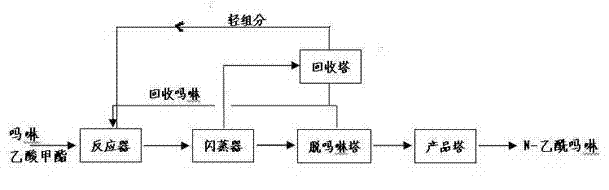

Preparation method for N-acetyl morpholine

A technology of acetylmorpholine and morpholine, applied in the field of morpholine products, can solve the problems of uneconomical, unit operation of increasing filtration, complicated process and the like, and achieve the effect of satisfying economical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

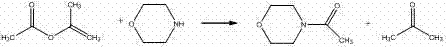

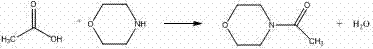

Method used

Image

Examples

Embodiment 1

[0066] Put the measured morpholine and methyl acetate into the reactor, replace oxygen with nitrogen, and close the reactor system. Start stirring, heat up, and total reflux. As the temperature rises, the material vaporizes, and the reactor pressure gradually rises. When the reaction temperature reaches 150°C, adjust the amount of nitrogen fed into the reaction system to make the system pressure reach 0.8MPa, a, adjust the heating heat and reflux cooling, and keep the reaction stable for 3 hours under this condition. After the reaction time was up, the stirring was stopped to end the reaction.

[0067] Maintain the pressure and temperature in the reactor, send the materials into the flash evaporator for flash evaporation, the flash evaporation temperature is controlled at 150°C (controlled by an external heating source), the pressure is 0.2MPa, a, and the flash vapor phase materials are mainly methyl acetate and Methanol, the morpholine content is about 17%, and the N-acetyl...

Embodiment 2

[0073] Same as Example 1, except that the reaction temperature is 150° C., the pressure is 1.0 MPa, a, and the reaction time is 3.5 hours. The yield in the reaction section is 79% (in terms of morpholine), and the yield and product quality in the separation section remain unchanged.

Embodiment 3

[0075] Same as Example 1, except that adiabatic flash evaporation is used for flash evaporation, the flash evaporation pressure is 0.2MPa, a, and the temperature is reduced to about 113°C. The process flow of the subsequent rectification section remains unchanged, and the process conditions are adjusted according to the ordinary rectification method. The overall yield and product quality were unchanged. But the whole technological process saves about 12% of energy consumption than example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com