Preparation method of alpha-cyclodextrin

A cyclodextrin, pH value technology, applied in the field of biochemistry, can solve the problems of high equipment requirements, high production costs, complicated operations, etc., and achieve the effects of simple equipment requirements, reduced production costs, and simple preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation principle of the present invention is to make a mixture of decyl alcohol and α-cyclodextrin by encapsulating α-cyclodextrin with decyl alcohol, and then use absolute ethanol to wash out decyl alcohol from α-cyclodextrin to make pure alpha-cyclodextrin. The decanol-absolute ethanol mixed solution washed out is recovered to ethanol, and the rest is decanol, which can be reused.

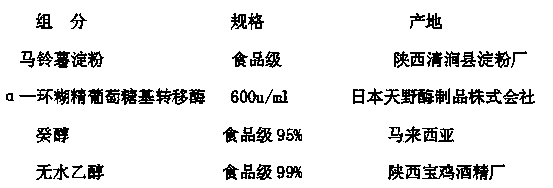

[0021] Raw materials and reagents in all following examples of the present invention are food grade, and its source and specification are as follows:

[0022]

[0023] In the embodiment, the detection of α-cyclodextrin content adopts high pressure liquid chromatography (the detection method comes from "China Food Additives" 2010.No.1Serial No.98(136-141) "High performance liquid chromatography for the determination of mixed ring α-cyclodextrin content in dextrin").

Embodiment 1

[0025] A kind of preparation method of α-cyclodextrin, comprises the following steps successively:

[0026] 1. Pretreatment: Add 50 grams of potato starch into 1000 ml of water under stirring conditions to make starch milk, adjust the pH value to 6.0, add 42 ml of cyclodextrin glucosyltransferase at 500 u per gram of dry starch, stir and heat up to 83 ±2°C for 10 minutes.

[0027] 2. Crude product generation: lower the temperature to 55±1°C, adjust the pH value to 5.0, add 58ml of cyclodextrin glucosyltransferase and 2.5ml of decanol according to 700u per gram of dry starch, and stir the reaction for 10 hours under this condition , stop responding.

[0028] 3. Refining: filter the reaction product of step 3 under airtight conditions, rinse the insoluble filter cake repeatedly with 1000 milliliters of water, collect the filter cake, and obtain 9.84 g of the filter cake. Add deionized water at a concentration of 5% to set the volume to 196.8ml, add 196.8ml of absolute ethanol,...

Embodiment 2

[0031] A kind of preparation method of α-cyclodextrin, comprises the following steps successively:

[0032] 1. Pretreatment: Add 50 grams of potato starch into 1000 ml of water under stirring conditions to make starch milk, adjust the pH value to 6.0, add 42 ml of cyclodextrin glucosyltransferase at 500 u per gram of dry starch, stir and heat up to 83 ±2°C for 10 minutes.

[0033] 2. Crude product generation: cool down to 55±1°C, adjust the pH value to 5.0, add 58ml of cyclodextrin glucosyltransferase and 5.0ml of decanol according to 700u per gram of dry starch, and stir for 10 hours under this condition , stop responding.

[0034] 3. Refining: the reaction product of step 3 was filtered under airtight conditions, and the insoluble matter filter cake was washed repeatedly with 1000 milliliters of water, and the filter cake was collected to obtain 12.8 g of the filter cake. Add deionized water at a concentration of 5% to set the volume to 256.0ml, add 256.0ml of absolute eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com