Preparation method of high-quality large-size monocrystal graphene

A single-crystal graphene, large-size technology, applied in the preparation of high-quality large-size single-crystal graphene, the field of preparing high-quality large-size single-crystal graphene, can solve the problem that graphene is prone to defects, affecting mobility and conductivity and other problems, to achieve the effect of low cost, large size and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

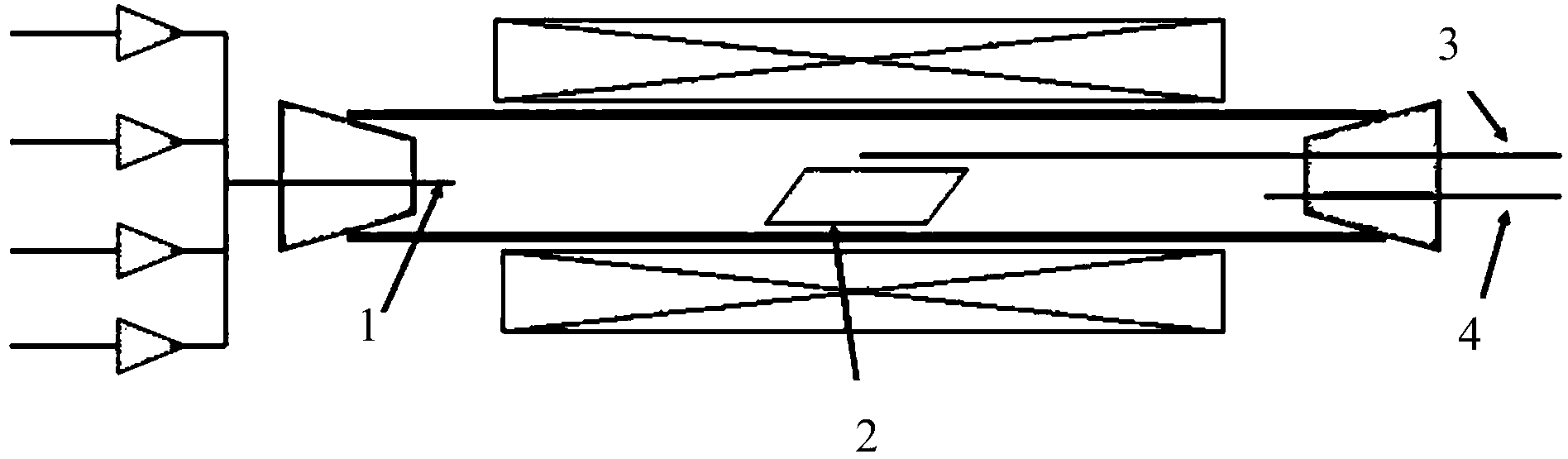

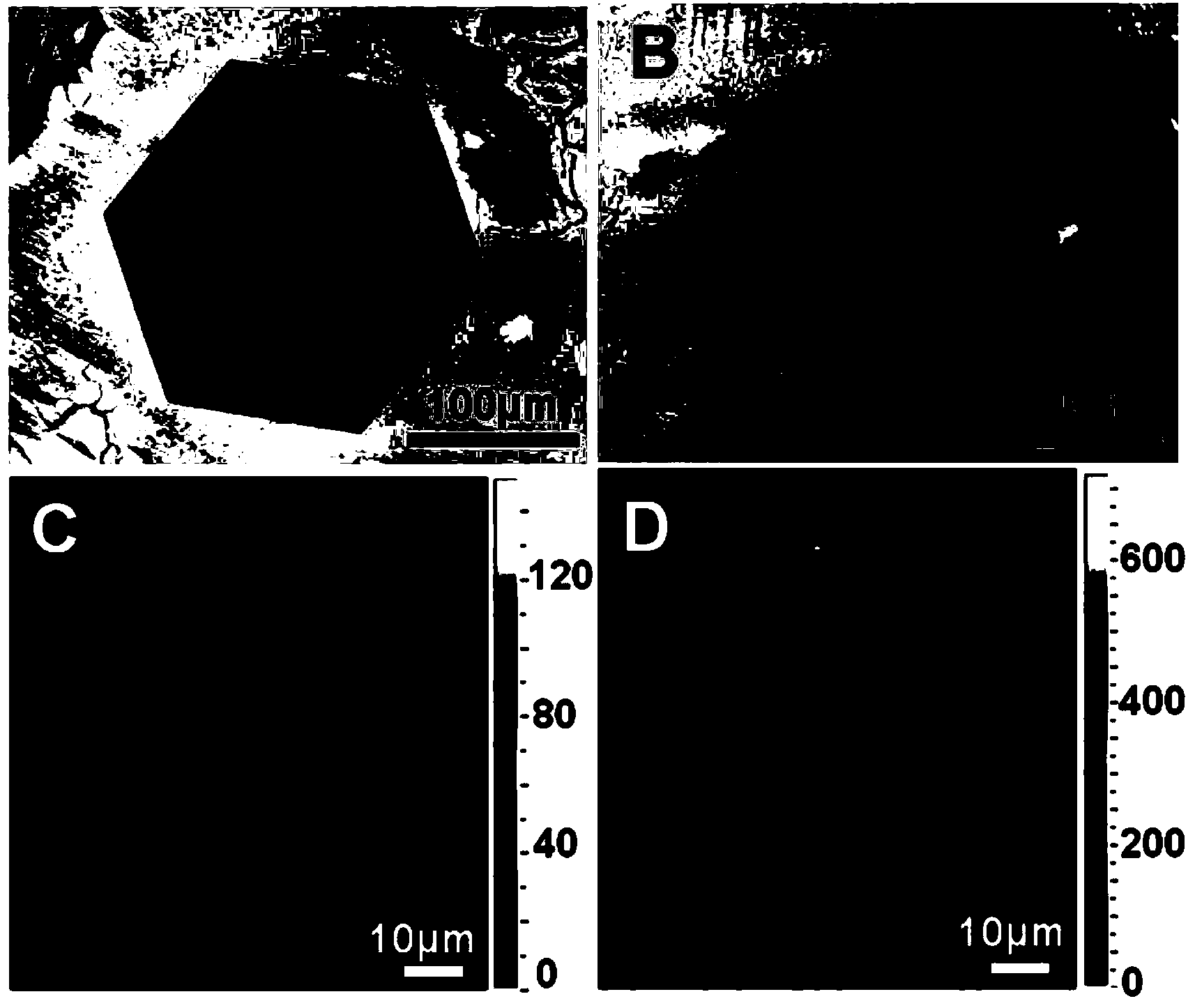

[0029] Such as figure 1 As shown, the present invention adopts a horizontal reaction furnace to grow graphene, and the two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 4, and the metal substrate 2 (platinum in this embodiment) is placed in the high temperature zone of the horizontal reaction furnace. The thermocouple 3 is located in the high temperature zone of the horizontal reactor to monitor the reaction temperature in real time. First, the polycrystalline platinum sheet (thickness 180 μm, length×width=20mm×16mm) was ultrasonically cleaned in acetone, water and ethanol for 40 minutes respectively. After cleaning, the platinum sheet was placed in a high-temperature furnace and annealed at 1100° C. for 10 hours to make the single grain reach the millimeter level (the size of the single grain in this embodiment is specifically 1 mm to 5 mm). Then, place the annealed platinum sheet in the central area of a horizontal r...

Embodiment 2

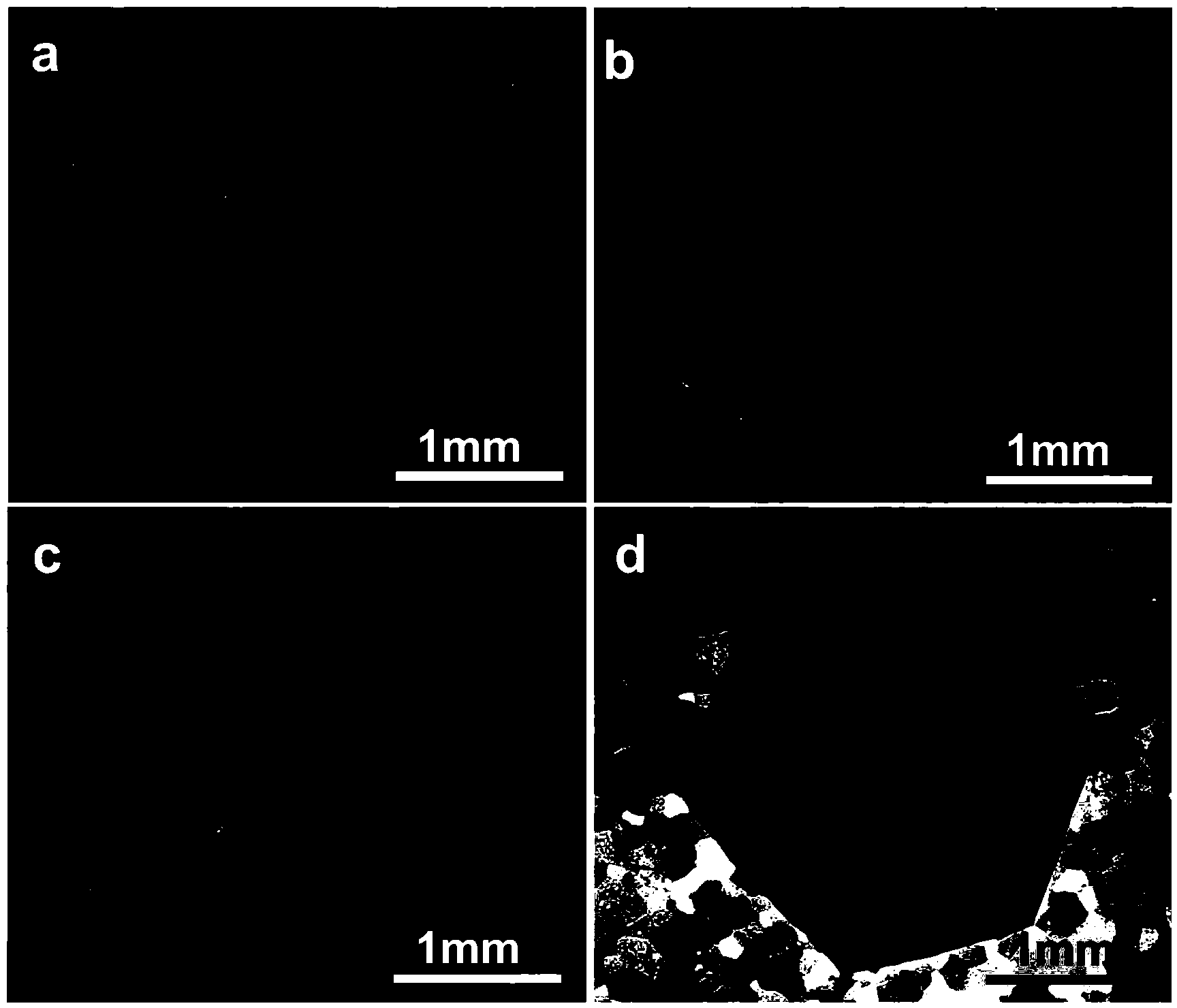

[0032] Such as figure 1 As shown, the present invention adopts a horizontal reaction furnace to grow graphene, and the two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 4, and the metal substrate 2 (platinum in this embodiment) is placed in the high temperature zone of the horizontal reaction furnace. The thermocouple 3 is located in the high temperature zone of the horizontal reactor to monitor the reaction temperature in real time. First, the polycrystalline platinum sheet (thickness 180 μm, length×width=5cm×5cm) was ultrasonically cleaned in acetone, water and ethanol for 40 minutes respectively. After cleaning, the platinum sheet was placed in a high-temperature furnace and annealed at 1100° C. for 10 hours to make the single grain reach the millimeter level (the size of the single grain in this embodiment is specifically 1 mm to 5 mm). Then, place the annealed platinum sheet in the central area of a horizontal rea...

Embodiment 3

[0035] Such as figure 1 As shown, the present invention adopts a horizontal reaction furnace to grow graphene, and the two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 4, and the metal substrate 2 (copper in this embodiment) is placed in the high temperature zone of the horizontal reaction furnace. The thermocouple 3 is located in the high temperature zone of the horizontal reactor to monitor the reaction temperature in real time. First, a polycrystalline copper sheet (thickness 25 μm, length × width = 5 cm × 5 cm) was ultrasonically cleaned in acetone, water, and ethanol for 40 minutes. After cleaning, the copper sheet was placed in a high-temperature furnace and annealed at 1083° C. for 10 hours to make the individual grains reach the millimeter level (the size of the individual grains in this embodiment is specifically 1 mm to 5 mm). Then, the annealed copper sheet is placed in the central area of a horizontal reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com