System for heating natural gas through gradient utilization of water supplied at medium pressure from waste heat boiler of gas turbine power plant

A technology of waste heat boiler and natural gas, which is applied in the direction of turbine/propulsion fuel delivery system, fuel heating and charging system of turbine/propulsion device, etc. It can solve the problems of small investment, large power consumption, and increased power consumption of power plants, and achieves The effect of low investment cost, natural gas saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

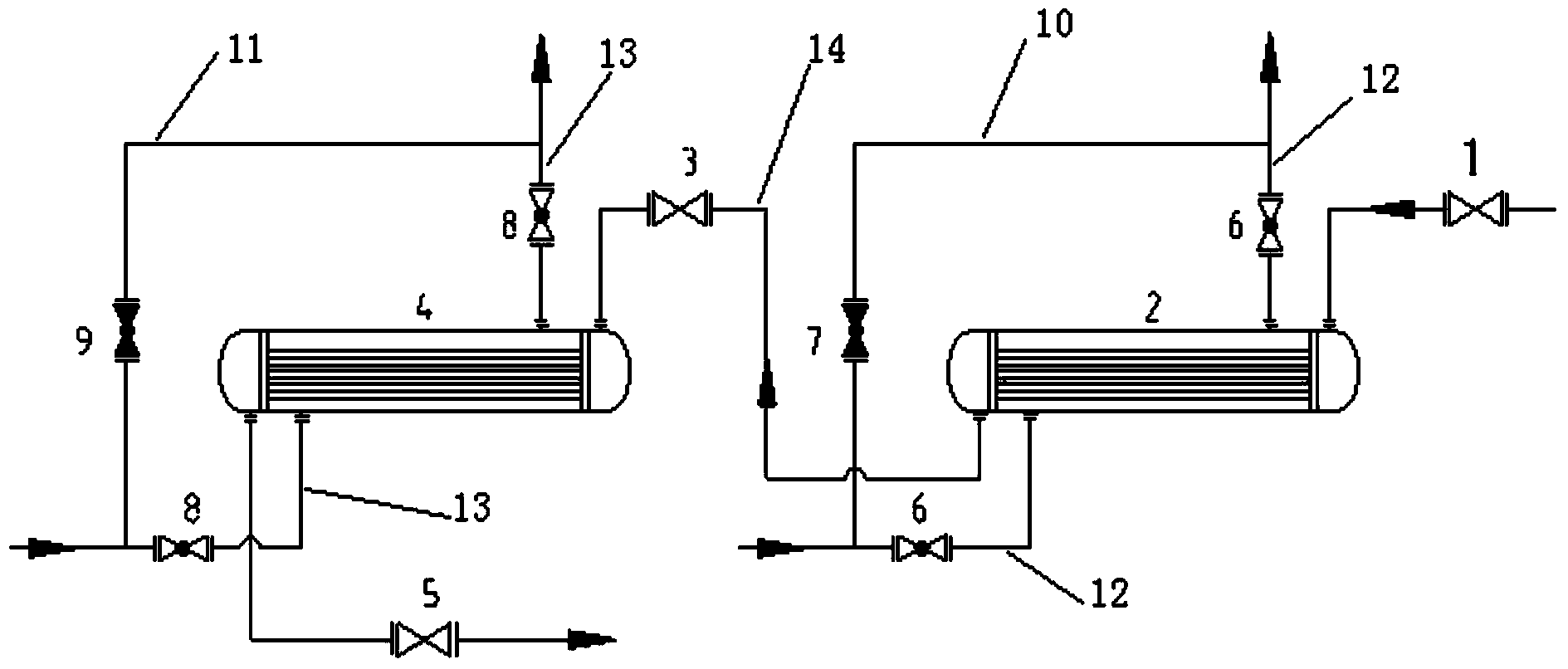

[0019] like figure 1 As shown, a cascade utilization of medium-pressure feedwater heating natural gas system for waste heat boilers in gas-fired power plants, which includes a performance heater 2, a natural gas heater 4, a pipeline I14 connecting the performance heater 2 and natural gas heater 4, pipeline I14 A cut-off valve II3 is arranged on the top; the air inlet and outlet of the performance heater 2 are respectively connected to the natural gas inlet and outlet pipes II12, and the natural gas outlet and inlet pipes II12 are connected to a bypass pipe IV10, and a normally closed valve is set on the bypass pipe IV10 The ball valve I7; the gas inlet and gas outlet of the natural gas heater 4 are respectively connected to the gas inlet and gas outlet pipelines III13, and the natural gas outlet and gas inlet pipelines III13 are connected to a bypass pipeline...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap