A process for surface texturing of crystalline silicon solar cells

A technology of solar cells and surface texture, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low battery conversion efficiency and inability to reduce reflection loss, and achieve good industrialization prospects, reduce reflection loss, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

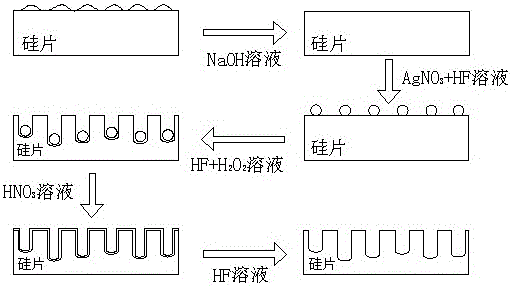

[0029] Such as figure 1 As shown, the general direction of this embodiment is that, first, the mechanical damage layer on the surface of the silicon wafer is removed by using NaOH solution; then, the AgNO 3 solution and HF solution were mixed to obtain silver particles, which were deposited on the surface of the silicon wafer; then, the HF solution and H 2 o 2 The solution is mixed and then reacts with the silicon wafer to form holes on the silicon wafer; 3 The solution removes the silver particles in the holes; finally, the HF solution is used to remove the oxide layer on the surface of the silicon wafer.

[0030] The following are the specific steps:

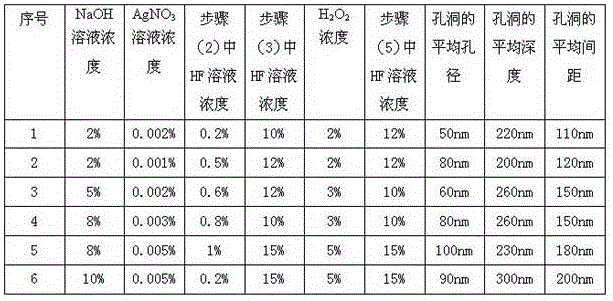

[0031] (1) Use NaOH solution with a concentration of 2%~10% to remove the mechanical damage layer on the surface of the silicon wafer, and the reaction time is 20~40 seconds;

[0032] (2) The concentration is 0.001%~0.005%AgNO 3 The solution is mixed with an HF solution with a concentration of 0.2-1%, and the mixed soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com