Tail gas separation tower

A separation tower and tail gas technology, applied in separation methods, separation devices, dispersed particle separation, etc., can solve the problems of high cost, large number of equipment, easy blockage, etc., and achieve the effect of large operation flexibility and high heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

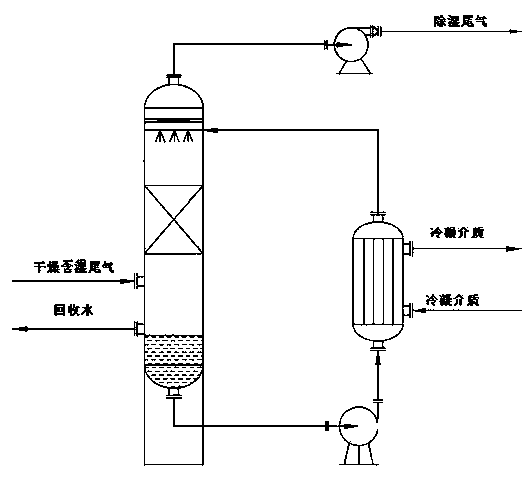

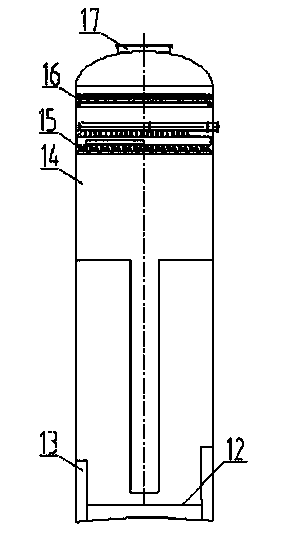

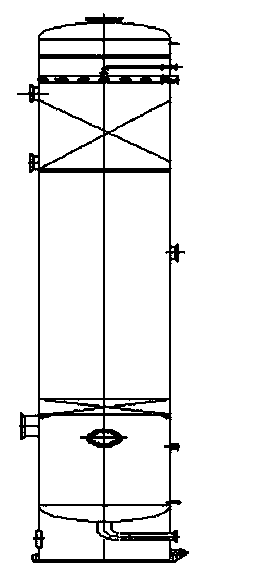

[0046] The technical scheme of the invention is further described below in conjunction with the process flow chart of the dry and wet tail gas separation tower:

[0047] Such as Figure 4-6As shown, under the action of the induced draft fan, the dry and wet tail gas at 85-150°C enters the dry and wet tail gas separation tower 18 . The dry and wet tail gas enters the spray section 6 from bottom to top through the inlet of the separation tower "I zone" and the distributor 5, and is sprayed, washed and cooled by the circulating cooling liquid. The dry and wet tail gas after spraying, washing and cooling enters the packing unit 7, and the circulating cooling liquid after flash cooling is sprayed evenly to the packing section 7 by the liquid distributor 8, and the gas (dry and wet tail gas) in the packing section 7 Liquid (circulating cooling liquid after flash evaporation) two-phase conducts countercurrent contact heat and mass exchange, the temperature of dry and wet tail gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com