Dye absorbent made of hazelnut shells

A hazelnut shell and adsorbent technology, which is applied in the field of dye adsorbent made of hazelnut shell, achieves the effects of simple process, resource utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

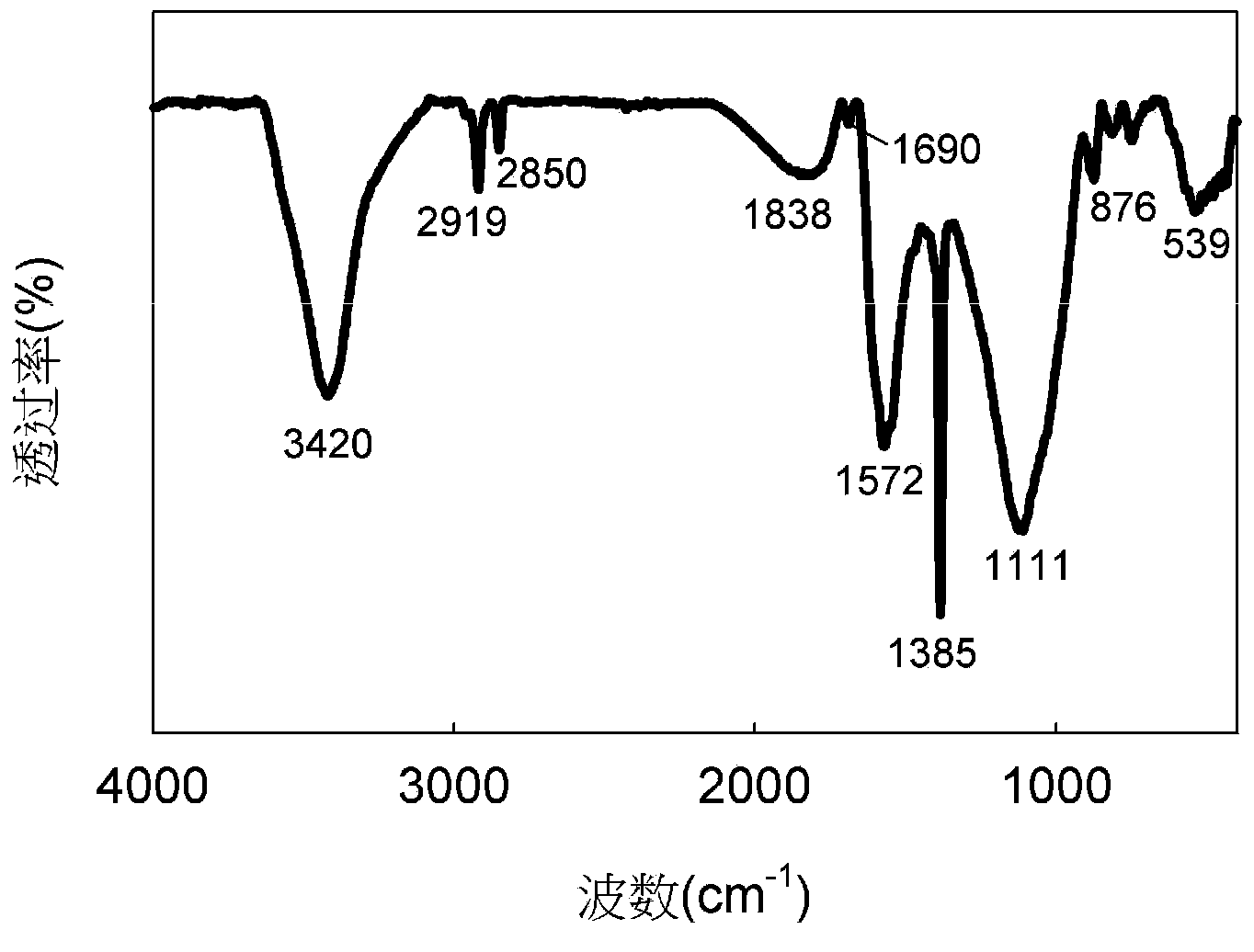

Image

Examples

Embodiment 1

[0019] Take a certain quality of hazelnut shells, wash the hazelnut shells with tap water, dry, crush and sieve to 300-600 μm, mix and impregnate the hazelnut shell particles with a 50% concentration of zinc chloride solution, treat with 320W microwave for 20 minutes, and use The obtained hazelnut shell biochar was pickled with a 10% hydrochloric acid solution, washed with distilled water until the pH was neutral, and dried to obtain a biochar dye adsorbent made of hazelnut shells.

[0020] At 25°C, add 0.1 g of the hazelnut shell biomass charcoal dye adsorbent prepared in this example to 50 mL of 1000 mg / L methylene blue solution, and after 24 hours of adsorption, filter and separate, and adjust the filtrate to neutral before discharging.

[0021] In this example, the yield of the dye adsorbent made from hazelnut shells was 42.19%, and the methylene blue adsorption value was 436.08 mg / g. The comparison of different adsorbents to the methylene blue adsorption capacity is shown...

Embodiment 2

[0025] Take a certain quality of hazelnut shells, wash the hazelnut shells with tap water, dry, crush and sieve to 600-800 μm, mix and impregnate the hazelnut shell particles with a zinc chloride solution with a concentration of 55%, treat them with 320W microwave for 18 minutes, and use The obtained hazelnut shell biochar was pickled with a 10% hydrochloric acid solution, washed with distilled water until the pH was neutral, and dried to obtain a biochar dye adsorbent made of hazelnut shells.

[0026] At 25°C, add 0.1 g of the hazelnut shell biomass charcoal dye adsorbent prepared in this example to 50 mL of 1000 mg / L rhodamine B solution, and after 24 hours of adsorption, filter and separate, and adjust the filtrate to neutral before discharging.

[0027] In this example, the yield of hazelnut shell biomass carbon dye adsorbent was 33.85%, and the adsorption value of rhodamine B was 499.85 mg / g. The adsorption capacity comparison of different adsorbents to rhodamine B is as ...

Embodiment 3

[0031] Take a certain quality of hazelnut shells, wash the hazelnut shells with tap water, dry, crush and sieve to 800-1000 μm, then mix and impregnate the hazelnut shell particles with a zinc chloride solution with a concentration of 60%, and treat them with 480W microwave for 15 minutes. The obtained hazelnut shell biochar was pickled with a 10% hydrochloric acid solution, washed with distilled water until the pH was neutral, and dried to obtain the hazelnut shell biochar dye adsorbent.

[0032] At 25°C, add 0.1 g of the hazelnut shell biochar dye adsorbent prepared in this example to 50 mL of 1000 mg / L reactive brilliant red K-2G solution, and after 24 hours of adsorption, filter and separate, adjust the filtrate to neutral and discharge.

[0033] In this example, the yield of hazelnut shell biomass carbon dye adsorbent was 40.77%, and the adsorption value of reactive brilliant red K-2G was 141.03mg / g. The adsorption capacity comparison of different adsorbents to active bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com