Fe-Mn loaded nanofiber membrane cadmium elimination material and preparation method thereof

A nanofiber membrane, carrier material technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., to achieve the effects of environmental friendliness, fast adsorption kinetics, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) 12.6 g ferrous sulfate (FeSO 4 ·7H 2 O) and 1.2 g potassium permanganate (KMnO 4 ) were each dissolved in 100 mL of deionized water, and under magnetic stirring conditions, the ferrous sulfate solution was slowly added to the potassium permanganate solution, and the stirring was continued for 2.0 hours. The entire experimental process was carried out at room temperature;

[0020] 2) Completely soak the polyacrylonitrile nanofiber membrane in the solution in step 1) for 5.0 hours;

[0021] 3) Heat the solution in step 2) to boiling under the condition of slow magnetic stirring, then slowly add 26 mL 5 M NaOH to the solution, stop heating and stirring after 30 minutes of reaction, and cool to room temperature;

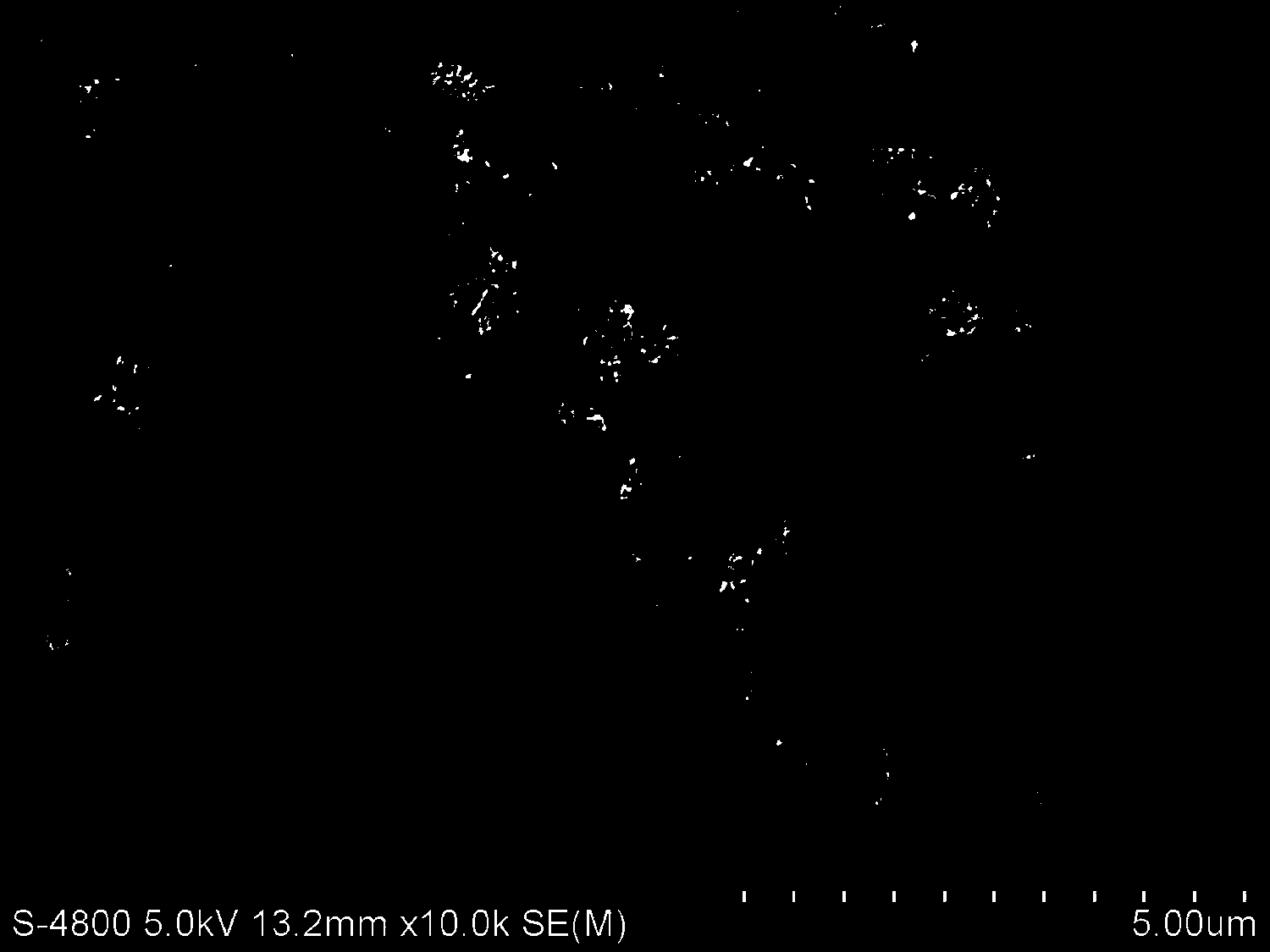

[0022] 4) Take out the polyacrylonitrile nanofiber membrane loaded with iron-manganese nano-oxide in step 3), wash it several times with deionized water until there is no material falling off the surface of the product, and then dry it in an oven at 80 °C for...

Embodiment 2

[0025] 1) 8.1 g ferric chloride (FeCl 3 ) and 1.2 g potassium permanganate (KMnO 4 ) were each dissolved in 100 mL of deionized water, and under magnetic stirring conditions, the ferrous sulfate solution was slowly added to the potassium permanganate solution, and the stirring was continued for 2.0 hours. The entire experimental process was carried out at room temperature;

[0026] 2) Completely soak the polystyrene nanofiber membrane in the solution in step 1) for 5.0 hours;

[0027] 3) Heat the solution in step 2) to boiling under the condition of slow magnetic stirring, then slowly add 26 mL 5 M NaOH to the solution, stop heating and stirring after 30 minutes of reaction, and cool to room temperature;

[0028] 4) Take out the polystyrene nanofiber membrane loaded with iron-manganese nano-oxide in step 3), wash it several times with deionized water until no material falls off the surface of the product, and then dry it in an oven at 80 °C for later use.

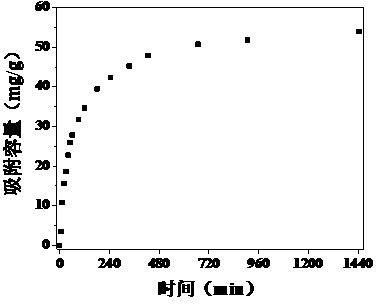

[0029] In order t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com