Catalyst for preparing tetrahydronaphthalene by naphthalene via selective hydrogenation as well as preparation method and application thereof

A naphthalene selectivity and catalyst technology, which is applied in the field of catalytic material preparation technology and application, can solve the problems of insufficient catalytic performance, low catalytic activity and selectivity, and small specific surface area of phosphide, so as to avoid cumbersome steps and environment Friendly, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

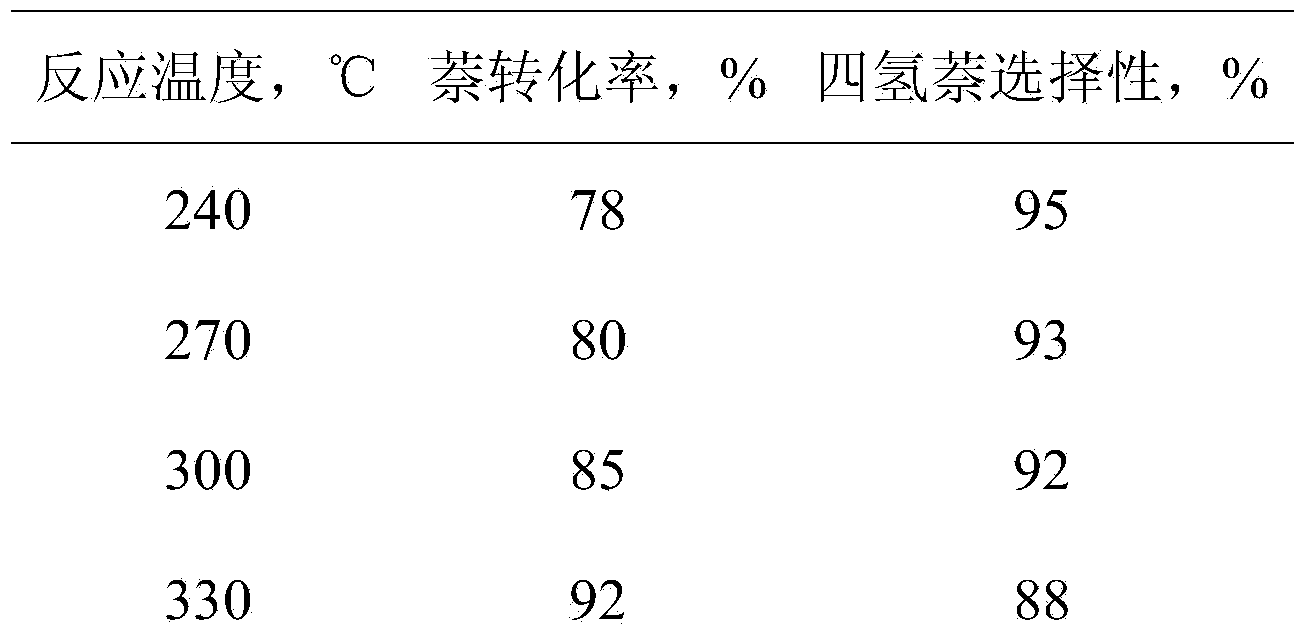

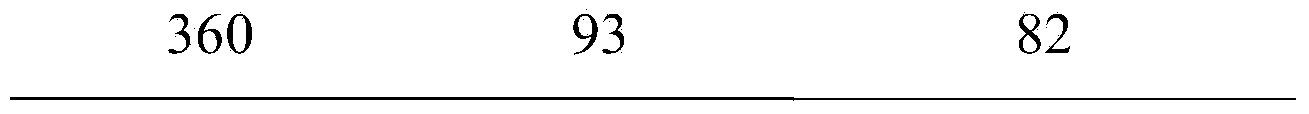

Examples

Embodiment 1

[0055] Embodiment 1: Preparation of Y molecular sieve supported molybdenum phosphide catalyst

[0056] Add a certain amount of diammonium hydrogen phosphate into deionized water (the mass fraction of the aqueous solution of diammonium hydrogen phosphate is 10-30wt%). After fully dissolving, add the measured ammonium molybdate and fully dissolve to form a clear and transparent solution.

[0057] Weigh the quantitative Y molecular sieve, place it in a vacuum device, keep it under the vacuum of 0.1MPa for 1 hour, and add the solution containing ammonium dihydrogen phosphate and ammonium molybdate under this vacuum degree, and after the Y molecular sieve is completely impregnated, put It was moved into a sonotrode and continued to immerse for 12 hours under 80HKz ultrasonic conditions.

[0058] Put the above impregnated body in the roasting equipment, heat to 120°C for 6 hours at a heating rate of 5°C / min in an air atmosphere to remove adsorbed water, and then heat to 350°C for 6 ...

Embodiment 2

[0061] Example 2: Preparation of cobalt phosphide / tungsten phosphide composite catalyst supported by beta / Y composite molecular sieve carrier

[0062] Add a certain amount of diammonium hydrogen phosphate into deionized water (the mass fraction of the aqueous solution of diammonium hydrogen phosphate is 10-30wt%). After fully dissolving, add the measured cobalt nitrate and ammonium metatungstate and fully dissolve to form Clear and transparent solution.

[0063] Weigh the quantitative beta / Y molecular composite sieve carrier, place it in a vacuum device, keep it under a vacuum of 0.02MPa for 8 hours, and add a solution containing ammonium dihydrogen phosphate, cobalt nitrate and ammonium metatungstate under this vacuum , after the beta / Y composite molecular sieve carrier is completely impregnated, move it into an ultrasonic generator, and continue impregnating for 8 hours under 30HKz ultrasonic conditions.

[0064] Put the above-mentioned impregnated body in the roasting equi...

Embodiment 3

[0067] Example 3: Preparation of beta / Y / ZSM-5 composite molecular sieve carrier loaded nickel phosphide / molybdenum phosphide composite catalyst

[0068] Add a certain amount of diammonium hydrogen phosphate into deionized water (the mass fraction of the aqueous solution of diammonium hydrogen phosphate is 10-30wt%). After fully dissolving, add the metered nickel nitrate and ammonium molybdate and fully dissolve to form a clear Clear solution.

[0069] Weigh the quantitative beta / Y / ZSM-5 molecular composite sieve carrier, place it in a vacuum device, add a solution containing ammonium dihydrogen phosphate, nickel nitrate and ammonium molybdate under normal pressure, and wait for the beta / Y / ZSM-5 compound After the molecular sieve carrier is completely impregnated, it is moved into an ultrasonic generator, and is continuously impregnated for 4 hours under the condition of 80Hz ultrasonic wave.

[0070] Put the above impregnated body in the roasting equipment, heat to 150°C at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com