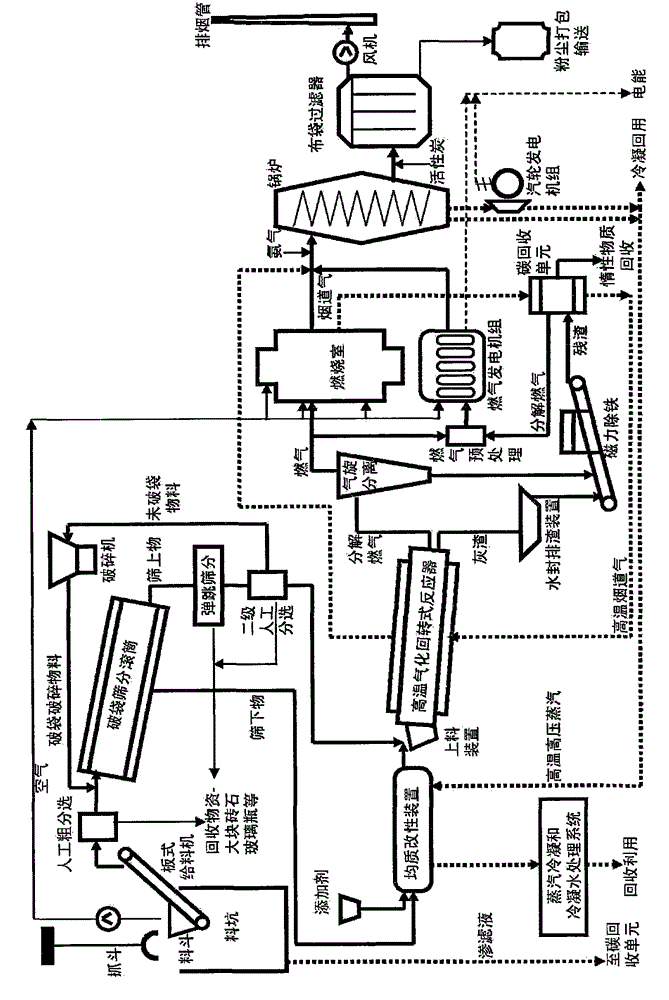

Solid waste homogeneous modified gasification clean power generation treatment method

A solid waste, homogeneous modification technology, applied in the direction of solid waste removal, machine/engine, mechanical equipment, etc. The effect of improving energy conversion efficiency, improving energy level, and reducing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The method of the present invention is applied in its entirety to treatment plants of mixed solid waste.

[0044] 1) Material storage and feeding: the solid waste material is sent into the material pit, and the material is sent to the apron feeder through the grab bucket, and is evenly transported to the manual sorting platform;

[0045] 2) Manual rough sorting: the material is manually sorted out by the manual sorting platform for super-large materials, large bricks and glass bottles with a diameter or length greater than or equal to 500mm;

[0046] 3) Bag breaking and screening: The material enters the screening drum equipped with a bag breaking tool inside and is screened according to the aperture. The material on the screen is screened out by a bouncing screening machine to screen out large bricks, and then sorted out by secondary manual sorting. Unopened bagged solid waste, while picking out the remaining glass bottles, large bricks, and oversized materials; unopen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com