Anti-blocking agent of fertilizer and application thereof

An anti-caking agent and fertilizer technology, applied in application, fertilizer mixture, fertilization device, etc., can solve the problems of low universality, uneven products, unsuitable for domestic production process, etc., and achieve strong universality and added Easy to use, conducive to the promotion of the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

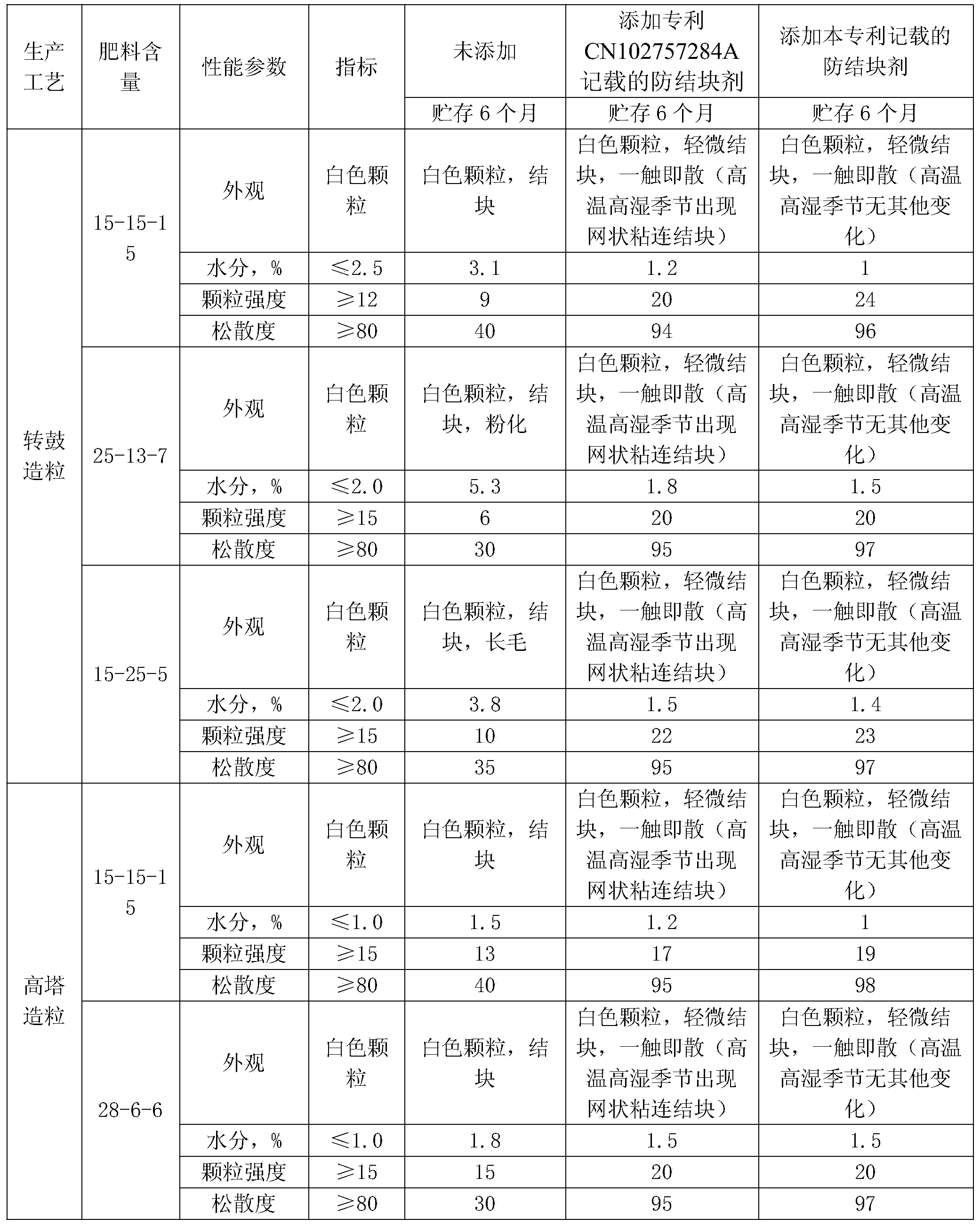

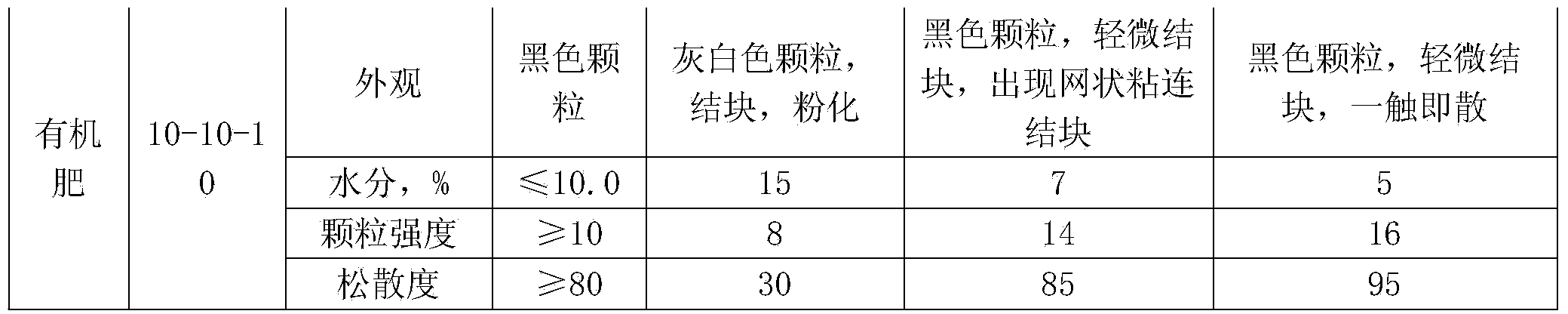

Examples

Embodiment 1

[0041] The present embodiment is the anti-caking agent (percentage by weight) of powder compound fertilizer containing the following components:

[0042] 70% mica, 2% stearic acid, 4% oleic acid amide, 4% higher carbon alcohol, 20% polystyrene modified by sodium polyacrylate.

[0043] Production method of the present invention is:

[0044] (1) Add 70kg of mica into a ball mill and grind to 800 mesh to obtain powder A, which is set aside;

[0045] (2) Add 20kg of polystyrene modified by sodium polyacrylate into the jet mill and grind to 800 mesh to obtain powder B for later use;

[0046] (3) Add 2kg of stearic acid, 4kg of oleic acid amide, and 4kg of high-carbon alcohol into the dissolution tank, and mix for 10 minutes to obtain mixture C, which is set aside;

[0047] (4) Put powder A and mixture C into the modification machine, carry out modification treatment, control the temperature at 100°C, stir for 30 minutes, cool down, and obtain powder D for later use.

[0048] (5)...

Embodiment 2

[0051] The present embodiment is the anti-caking agent (percentage by weight) of powder compound fertilizer containing the following components:

[0052] 50% mica, 10% vermiculite, 10% illite, 2% stearic acid, 4% high carbon alcohol, 4% C22 alkylamine, cross-linked low-substituted hydroxypropyl cellulose (L-HPC) modified 10% polyethylene, 10% polypropylene modified by sodium polyacrylate.

[0053] Production method of the present invention is:

[0054] (1) Put 50Kg of mica, 10Kg of vermiculite, and 10Kg of illite into the mixer, mix for 10 minutes, then add it into a ball mill and grind it to 800 mesh to obtain powder A for use;

[0055] (2) Add 10Kg of sodium polyacrylate-modified polypropylene and 10Kg of modified low-substituted hydroxypropyl cellulose-modified polyethylene into a jet mill and grind to 800 mesh to obtain powder B for later use;

[0056] (3) Add 2kg of stearic acid, 4kg of higher alcohol, and 4kg of C22 alkylamine into the dissolving tank, and mix for 10 m...

Embodiment 3

[0061] The present embodiment is the anti-caking agent (percentage by weight) of powder compound fertilizer containing the following components:

[0062] Mica 50%, clay 5%, vermiculite 15%, silane coupling agent kh560: 2%, higher alcohol 4%, C22 alkylamine 4%, cross-linked PVP modified polypropylene 10%, CMS- Na modified polystyrene 10%.

[0063] Production method of the present invention is:

[0064] (1) Put 50Kg of mica, 15Kg of vermiculite, and 5Kg of white clay into the mixer, mix for 10 minutes, then add it into a ball mill and grind it to 800 mesh to obtain powder A for later use;

[0065] (2) Add 10Kg of CMS-Na-modified polystyrene and 10Kg of cross-linked PVP-modified polypropylene into the jet mill and grind to 800 mesh to obtain powder B for later use;

[0066] (3) Add 2kg of silane coupling agent, 4kg of higher alcohol, and 4kg of C22 alkylamine into the dissolution tank, and mix for 10 minutes to obtain mixture C, which is set aside;

[0067] (4) Put powder A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com