The preparation method of propylene

A technology for dehydrogenation of propylene and propane, applied in chemical instruments and methods, inorganic chemistry, hydrocarbons, etc., can solve the problems of short catalyst regeneration cycle, high equipment investment and energy consumption, low purity of circulating hydrogen, etc., and achieves low price. , The effect of low equipment investment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

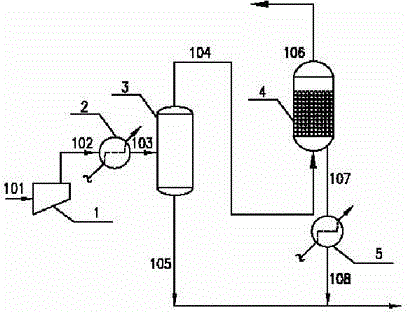

[0020] A 600,000-ton / year propane dehydrogenation to propylene unit (annual operating hours 8,000 hours), usingfigure 1 After the propane dehydrogenation reaction, the gas is compressed to 1.0MPa by a one-stage reciprocating compressor and cooled to 45°C. The gas phase flow enters the adsorption tower for adsorption. There are 4 adsorption towers, and the porous stable state γ-alumina is used for adsorption According to the two basic steps of high-pressure adsorption and low-pressure regeneration switching, repeat the cycle operation, that is, there is always one container in the adsorption state, while the other several are in different regeneration stages, the switching regeneration time is 600 seconds, and the adsorption tower is adsorbed. The pressure is 1.0MPa, temperature 40℃, desorption regeneration pressure 0MPaG.

[0021] The processing capacity of the adsorption tower of the device is 35% of the reaction gas, the diameter of the adsorption tower is 3000mm, the purity ...

Embodiment 2

[0023] A 600,000-ton / year propane dehydrogenation to propylene unit (annual operating hours 8,000 hours), using figure 1 Advanced process technology, the gas after the propane dehydrogenation reaction is compressed to 1.5MPa by a one-stage reciprocating compressor, and cooled to 15°C, the gas phase flow enters the adsorption tower for adsorption, and there are 6 adsorption towers, using 4A molecular sieve as the adsorbent, switching regeneration The time is 360 seconds, the pressure is 1.5MPa when the adsorption tower is adsorbed, and other conditions are the same as in Example 1.

[0024] The processing capacity of the adsorption tower of the device is 20% of the reaction gas, the diameter of the adsorption tower is 2800mm, the purity of hydrogen is 99.9% (volume), the selectivity of propylene in propane dehydrogenation reaction is 91%, the catalyst regeneration cycle is 2 days, and the service life is 2 years. The steam consumption is 28 tons / hour, the electricity consumptio...

Embodiment 3

[0026] A 600,000-ton / year propane dehydrogenation to propylene unit (annual operating hours 8,000 hours), using figure 1 After the propane dehydrogenation reaction, the gas is compressed to 1.0MPa by a one-stage reciprocating compressor and cooled to 15°C. The gaseous phase flow enters the adsorption tower for adsorption. The pressure of the adsorption tower is -0.08MPa when it is desorbed. Other conditions are the same as in the example 1.

[0027] The processing capacity of the adsorption tower of the device is 25% of the reaction gas, the diameter of the adsorption tower is 3000mm, the purity of hydrogen is 99.95% (volume), the selectivity of propylene in propane dehydrogenation reaction is 92%, the catalyst regeneration cycle is 3 days, and the service life is 2 years. The steam consumption is 26 tons / hour, the electricity consumption is 6500kw, and the total investment is about 2 billion yuan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com