Synthesis method for triethyl orthoformate

A technology of triethyl orthoformate and ethanol, which is applied in the field of synthesis of triethyl orthoformate, can solve the problems of product damage, reduced output of triethyl orthoformate, and imperfect dehydration efficiency, etc., and achieves reduced loss and simple synthesis method Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

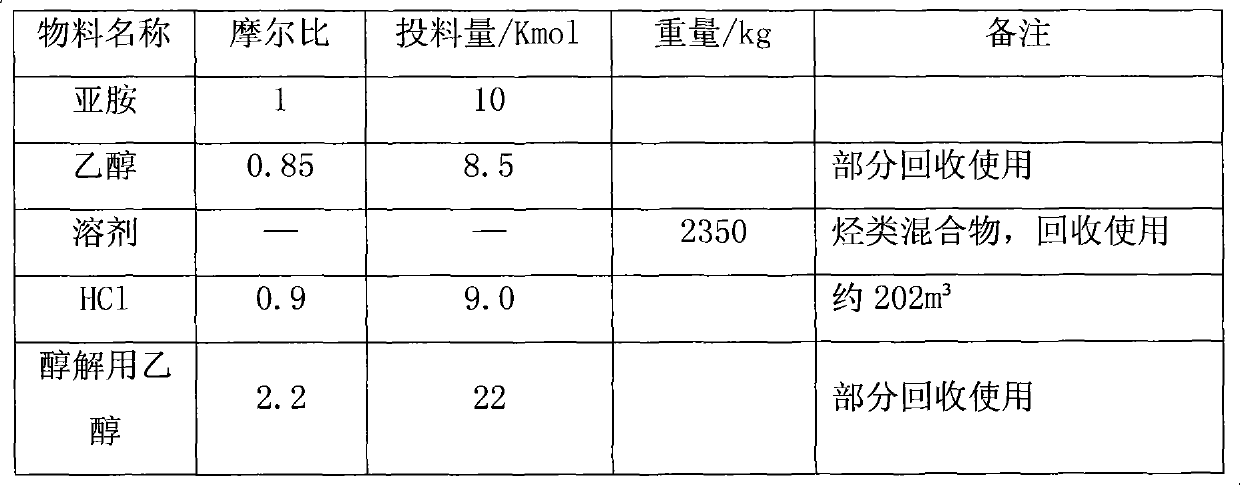

Embodiment 1

[0021] A kind of synthetic method of triethyl orthoformate, it comprises the steps:

[0022] First add 60% solvent to the neutralization crystallization kettle, cool down to about 0°C, add ethanol, continue to cool down to minus 5°C, add dehydrating agent, the amount of dehydrating agent added is 1% of the solvent mass, and then pass HCl gas , continue to cool down to minus 7°C, add imine, and then slowly add another 40% solvent, after 1 hour, the neutralization and crystallization is completed, discharge the material into the alcoholysis kettle, heat up to about 20°C, add ethanol for alcoholysis, and keep warm After reacting for 10 hours, carry out centrifugation to obtain the mixed solution, and then distill to obtain the finished triethyl orthoformate, and the solid obtained by centrifugation is ammonium chloride, which is then sold as a by-product.

[0023] The above-mentioned dehydrating agent is composed of glycerol, activated clay and 4A molecular sieve, and the mass ra...

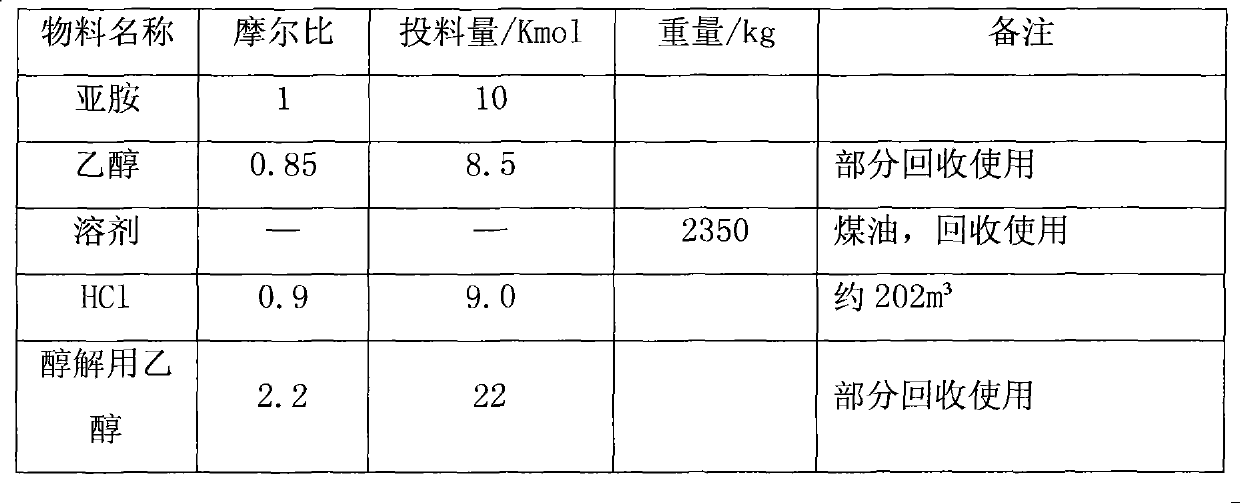

Embodiment 2

[0028] A kind of synthetic method of triethyl orthoformate, it comprises the steps:

[0029] First add 60% solvent to the neutralization crystallization kettle, cool down to about 0°C, add ethanol, continue to cool down to minus 5°C, add dehydrating agent, the amount of dehydrating agent added is 2% of the solvent mass, and then pass HCl gas , continue to cool down to minus 7°C, add imine, and then slowly add another 40% solvent, after 1 hour, the neutralization and crystallization is completed, discharge the material into the alcoholysis kettle, heat up to about 20°C, add ethanol for alcoholysis, and keep warm After reacting for 10 hours, carry out centrifugation to obtain the mixed solution, and then distill to obtain the finished triethyl orthoformate, and the solid obtained by centrifugation is ammonium chloride, which is then sold as a by-product.

[0030] The above-mentioned dehydrating agent is composed of glycerol, activated clay and 4A molecular sieve, and the mass ra...

Embodiment 3

[0036] The dehydration effect comparison of dehydrating agent of the present invention:

[0037] Groups: divided into four groups, wherein, control group 1: without adding any dehydrating agent; control group 2: glycerol; control group 3: glycerol+4A molecular sieve (mass ratio is 5: 1); the present invention: Glycerol + activated clay + 4A molecular sieve (mass ratio is 5:1:1). The added amount of the above-mentioned dehydrating agent is 2% of the solvent mass. Moisture and triethyl orthoformate product yield in the mixed solution after detecting alcoholysis, specifically refer to table 3:

[0038] table 3

[0039] group

[0040] Conclusion: the dehydrating agent of the present invention is obviously better than the glycerol dehydrating agent and the molecular sieve dehydrating agent in the prior art, and the dosage is small, so that the moisture is greatly reduced and the yield of triethyl orthoformate is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com