Preparation method of L-alpha-choline glycerophosphate

A technology of choline alfoscerate and phosphoryl choline, which is applied in the field of chemical synthesis of L-alpha-choline alfoscerate, which can solve the problems of unfavorable labor protection and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

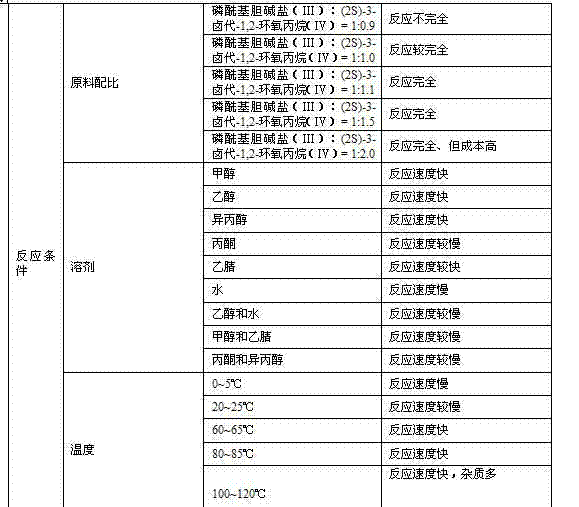

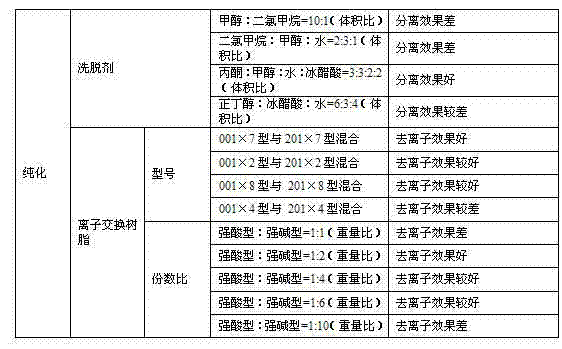

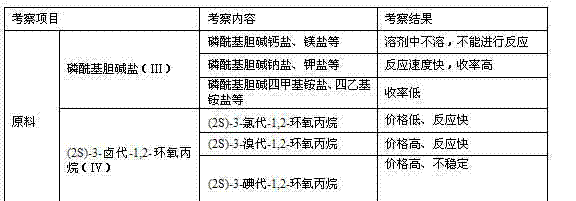

Method used

Image

Examples

reference example 1

[0044] Preparation of Phosphorylcholine Sodium Salt

[0045] In the reaction bottle, add phosphorylcholine calcium salt (II) 15.00g (0.046mol) and water 75ml, stir until dissolved, add dropwise the sodium carbonate solution prepared by anhydrous sodium carbonate 9.65g and water 30ml, drop After completion, stir at room temperature for 2 hours, filter, and evaporate to dryness under reduced pressure to obtain 11.00 g of phosphorylcholine sodium salt, with a yield of 91.70% and an HPLC purity of 96.50%.

reference example 2

[0047] Preparation of Phosphorylcholine Potassium Salt

[0048]The operation was the same as in Reference Example 1, and anhydrous potassium carbonate was used instead of anhydrous sodium carbonate to obtain 12.60 g of phosphorylcholine potassium salt with a yield of 93.69% and an HPLC purity of 92.81%.

reference example 3

[0050] Preparation of Phosphorylcholine Tetramethylammonium Salt

[0051] In the reaction flask, add 15.00g (0.046mol) of phosphorylcholine calcium salt (II) and 75ml of water, stir until dissolved, add 4.05g of oxalic acid, heat up to 40°C for 4h, filter, and evaporate the filtrate to dryness under reduced pressure to obtain Dissolve the oil in 60ml of methanol, add 8.10g of tetramethylammonium hydroxide pentahydrate, react for 3h, and evaporate to dryness under reduced pressure to obtain 11.25g of phosphorylcholine tetramethylammonium salt, with a yield of 84.68% and a purity of 90.85% by HPLC.

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com