Separation and purification method of pachymic acid monomer

A technology for separation and purification of tacosic acid, applied in chemical recovery, organic chemistry, steroids, etc., can solve the problems of inability to industrialize production, high preparation cost, complicated process, etc., and achieve cost saving of reagents, easy operation and high product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

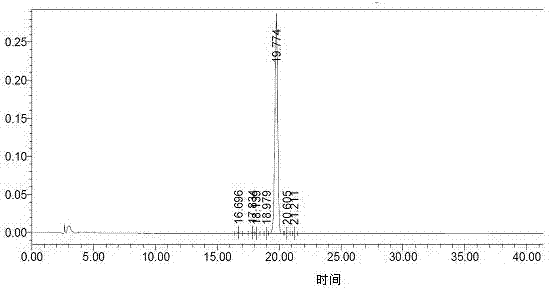

Image

Examples

Embodiment 1

[0035] A. Extraction

[0036] Grind 250 g of Poria cocos into coarse powder, add 2.0 L of ethanol solution with a mass percentage concentration of 95%, reflux extraction 3 times, each time for 1.5 hours, filter the extract, combine the filtrate, concentrate under reduced pressure to recover ethanol, and obtain a concentrated extract The relative density is 1.32 (50°C), and the volume is 160ml;

[0037] B. Extraction

[0038] Add 1.6L of water to the concentrated extract obtained in step A to disperse, extract 3 times with petroleum ether, remove the petroleum ether extract, extract the aqueous phase 5 times with ethyl acetate, combine the ethyl acetate extract, reclaim the filtrate to dryness, and obtain Off-white pachymic acid crude product 1.4g;

[0039] C. crystallization

[0040] Completely dissolve the off-white solid obtained in step B with 140ml of acetone, filter it with a nano-organic membrane, add 280ml of distilled water to the filtrate, refrigerate and crystalli...

Embodiment 2

[0042] A. Extraction

[0043] Grind 250 g of Poria cocos into coarse powder, add 2.5 L of ethanol solution with a mass percentage concentration of 95%, reflux extraction 4 times, each time for 2 hours, filter the extract, combine the filtrate, concentrate under reduced pressure to recover ethanol, and obtain a concentrated extract The relative density is 1.35 (50°C), and the volume is 120ml;

[0044] B. Extraction

[0045] Add 1.2 L of water to the concentrated extract obtained in step A to disperse, extract 3 times with petroleum ether, remove the petroleum ether extract, extract the aqueous phase with ethyl acetate 6 times, combine the ethyl acetate extract, and recover the filtrate to dryness to obtain Off-white pachymic acid crude product 1.55g;

[0046] C. crystallization

[0047] Completely dissolve the off-white solid obtained in step B with 310ml of acetone, filter it with a nano-organic membrane, add 930ml of distilled water to the filtrate for refrigeration and cr...

Embodiment 3

[0049] A. Extraction

[0050] Grind 250 g of Poria cocos into coarse powder, add 2.5 L of ethanol solution with a mass percentage concentration of 95%, reflux extraction 3 times, each time for 2 hours, filter the extract, combine the filtrate, concentrate under reduced pressure to recover ethanol, and obtain a concentrated extract The relative density is 1.30 (50°C), and the volume is 130ml;

[0051] B. Extraction

[0052]Add 1.3 L of water to the concentrated extract obtained in step A to disperse, extract 4 times with petroleum ether, remove the petroleum ether extract, extract the aqueous phase with ethyl acetate 4 times, combine the ethyl acetate extract, reclaim the filtrate to dryness, and obtain Off-white pachymic acid crude product 1.3g;

[0053] C. crystallization

[0054] Completely dissolve the off-white solid obtained in step B with 390ml of acetone, filter it with a nano-organic membrane after dissolution, add 1460ml of distilled water to the filtrate for refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com