PVC (polyvinyl chloride) plastic building template

A construction formwork and polyvinyl chloride technology, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of increasing labor costs, affecting the construction period, poor heat resistance, light resistance, etc., and can improve the surface finish , Improve flatness, prevent cell collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

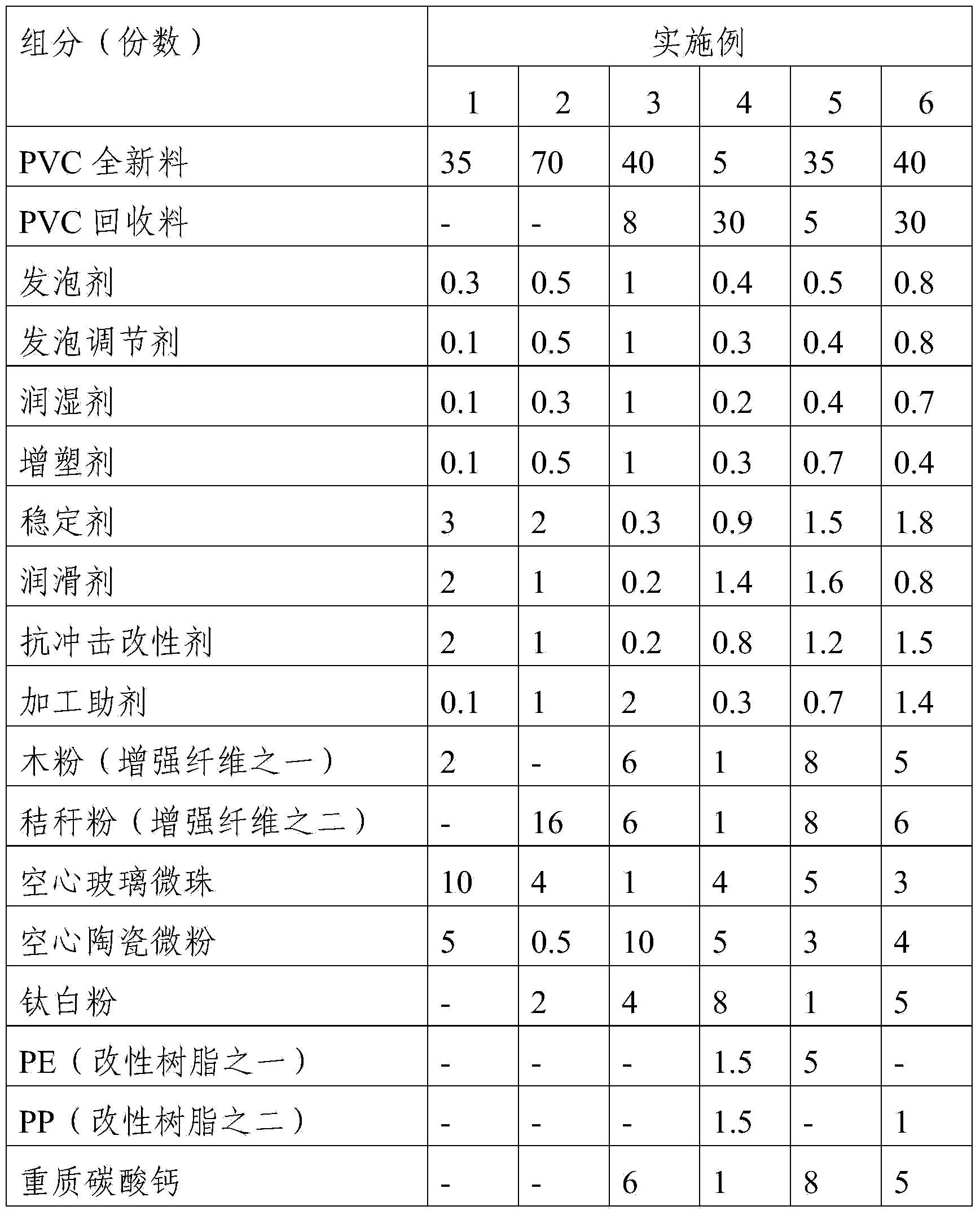

[0044] The present invention is a polyvinyl chloride plastic building formwork, and its raw material composition and mass parts in Examples 1-6 are shown in Table 1.

[0045] Table 1:

[0046]

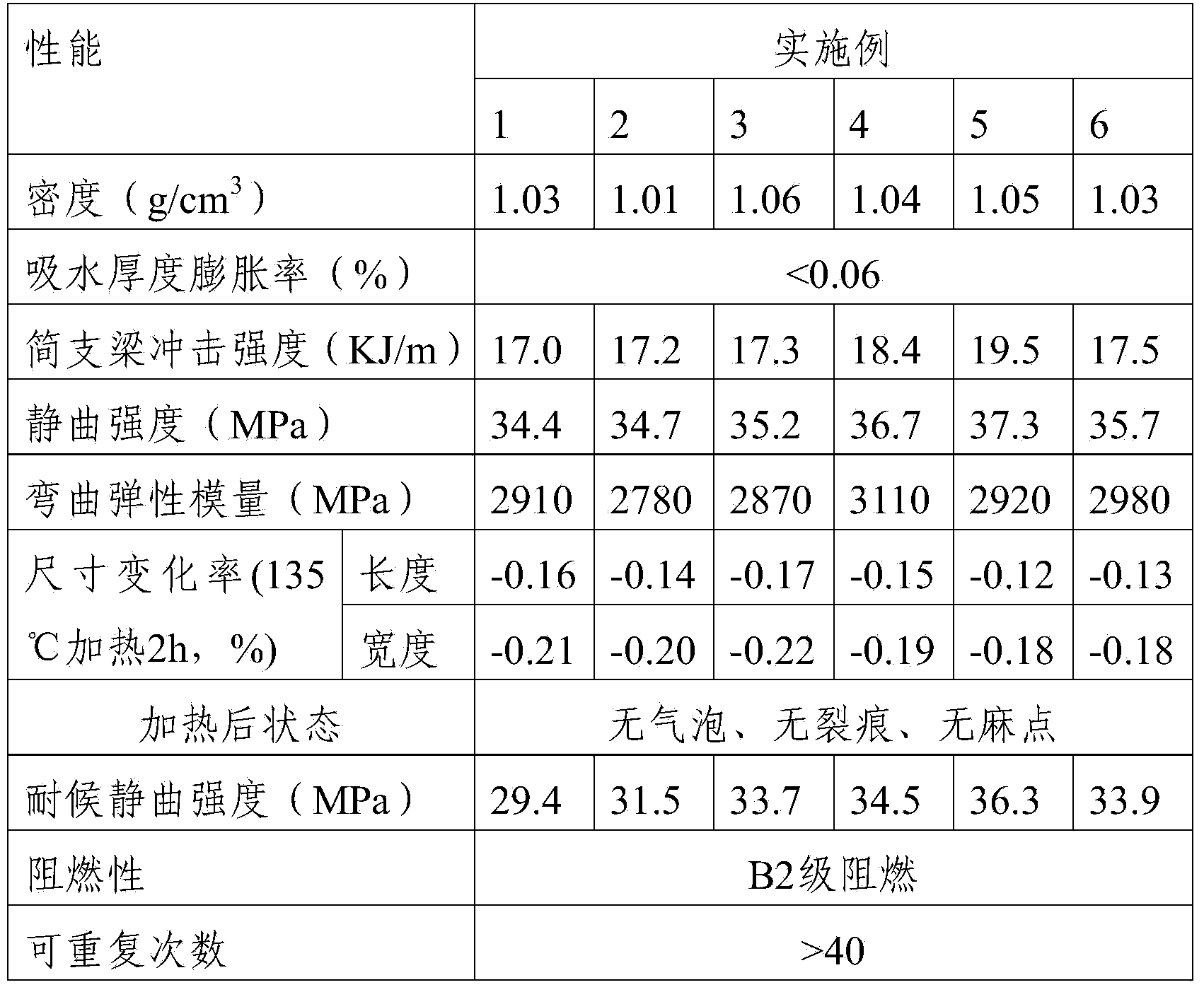

[0047] Among embodiments 1-6, owing to adopting hollow glass microsphere and hollow ceramic micropowder to mix and use to fill PVC and make building formwork, pouring object surface is smooth and attractive in appearance, have surpassed the technical requirement of existing fair-faced concrete formwork, have eliminated concrete surface two Compared with the corresponding PVC building formwork filled with hollow glass micropowder without hollow ceramic micropowder filling, it can shorten the construction period by more than 30%.

Embodiment 2

[0048] In Example 2, anatase titanium dioxide was added to increase the whiteness of the building formwork, while improving the aging resistance and heat absorption of the building formwork; in Examples 3 to 6, PVC was made of recycled PVC and new PVC materials It is mixed as the main raw material, and rutile titanium dioxide is added to the raw material formula at the same time, and the resulting building formwork still has good whiteness. Compared with anatase titanium dioxide, rutile titanium dioxide can improve the ultraviolet light absorption and shielding performance of building templates, and improve the aging resistance of building templates.

Embodiment 4

[0049] The recycled PVC material in Example 4 and Example 6 is hard PVC recycled material, and the recycled PVC material in Example 5 is soft PVC recycled material. When using soft PVC reclaimed materials, the amount added should not exceed 20% of the total weight of PVC, otherwise it will affect the hardness of the finished product. If hard PVC reclaimed materials are used, the added amount can even reach about 85% of the total weight of PVC. , thus more effectively reducing the manufacturing cost of PVC building formwork.

[0050] In Examples 4 to 6, PP and / or PE plastic particles were also added as modified resins to overcome the disadvantage of poor PVC processing fluidity and reduce its brittle-ductile transition temperature to below -10°C, so that the building formwork can withstand Use in low temperature conditions in winter. The impact strength of the simply supported beam of the corresponding product reaches above 17.5KJ / m.

[0051] In Examples 3 to 6, the heavy cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com