Mesoporous carbon/RuO2 composite material for supercapacitor and preparation method thereof

A technology of supercapacitors and composite materials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., to achieve the effects of simple preparation methods, easy implementation, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Synthesis of precursor phenolic resin: Melt phenol at 40°C, add 20wt% NaOH solution and 37wt% formaldehyde solution in turn, heat, stir at 80°C for 1 hour to obtain a brownish-yellow solution, cool to room temperature, and use HCl solution Adjust the pH to 7. Moisture was removed under vacuum to obtain anhydrous phenolic resin, which was formulated into 20wt% phenolic resin ethanol solution.

[0034]2. Assembly of ordered intermediate polymer: Dissolve Pluronic amphiphilic block copolymer (F127) in ethanol solution, then add the phenolic resin ethanol solution prepared in step 1, and stir to obtain a uniform solution , wherein the molar ratio of amphiphilic block copolymer, phenol, formaldehyde, and ethanol is 0.005:1:2:30. The above solution was transferred to a petri dish, and ethanol was volatilized at room temperature for 8 hours to form a transparent film, and then the petri dish was dried in an oven at 100°C for 24 hours to obtain an ordered intermediate polym...

Embodiment 2

[0041] A method for preparing a composite mesoporous carbon-based electrode material for supercapacitors, specifically comprising the following steps:

[0042] 1. Synthesis of precursor phenolic resin: Melt phenol at 50°C, add NaOH solution and 37 wt% formaldehyde solution in sequence, heat, stir at 70°C for 1.5h to obtain a brown-yellow solution, cool to room temperature, and use HCl solution Adjust the pH to 7. Moisture was removed under vacuum to obtain anhydrous phenolic resin, which was formulated into 20wt% phenolic resin ethanol solution.

[0043] 2. Assembly of ordered intermediate polymers: Dissolve Pluronic amphiphilic block copolymers (F123 and F68) in ethanol solution, then add the phenolic resin ethanol solution prepared in step 1, and stir A homogeneous solution was obtained, wherein the molar ratio of the amphiphilic block copolymer, phenol, formaldehyde, and ethanol was 0.015:1:2:50. The above solution was transferred to a petri dish, and ethanol was volatili...

Embodiment 3

[0050] A method for preparing a composite mesoporous carbon-based electrode material for supercapacitors, specifically comprising the following steps:

[0051] 1. Synthesis of precursor phenolic resin: Melt phenol at 60°C, add NaOH solution and 37wt% formaldehyde solution in turn, heat, stir at 80°C for 1 hour to obtain a brownish-yellow solution, cool to room temperature, and use HCl solution to adjust the pH Adjust to 7. Moisture was removed under vacuum to obtain anhydrous phenolic resin, which was formulated into 20wt% phenolic resin ethanol solution.

[0052] 2. Assembly of ordered intermediate polymer: Dissolve Pluronic amphiphilic block copolymer (F68) in ethanol solution, then add the phenolic resin ethanol solution prepared in step 1, and stir to obtain a uniform solution , wherein the molar ratio of copolymer, phenol, formaldehyde, and ethanol is 0.03:1:2:70. The above solution was transferred to a petri dish, and ethanol was volatilized at room temperature for 12 ...

PUM

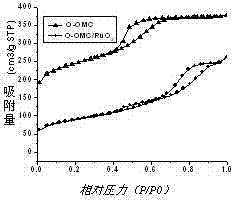

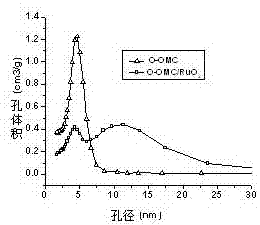

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com