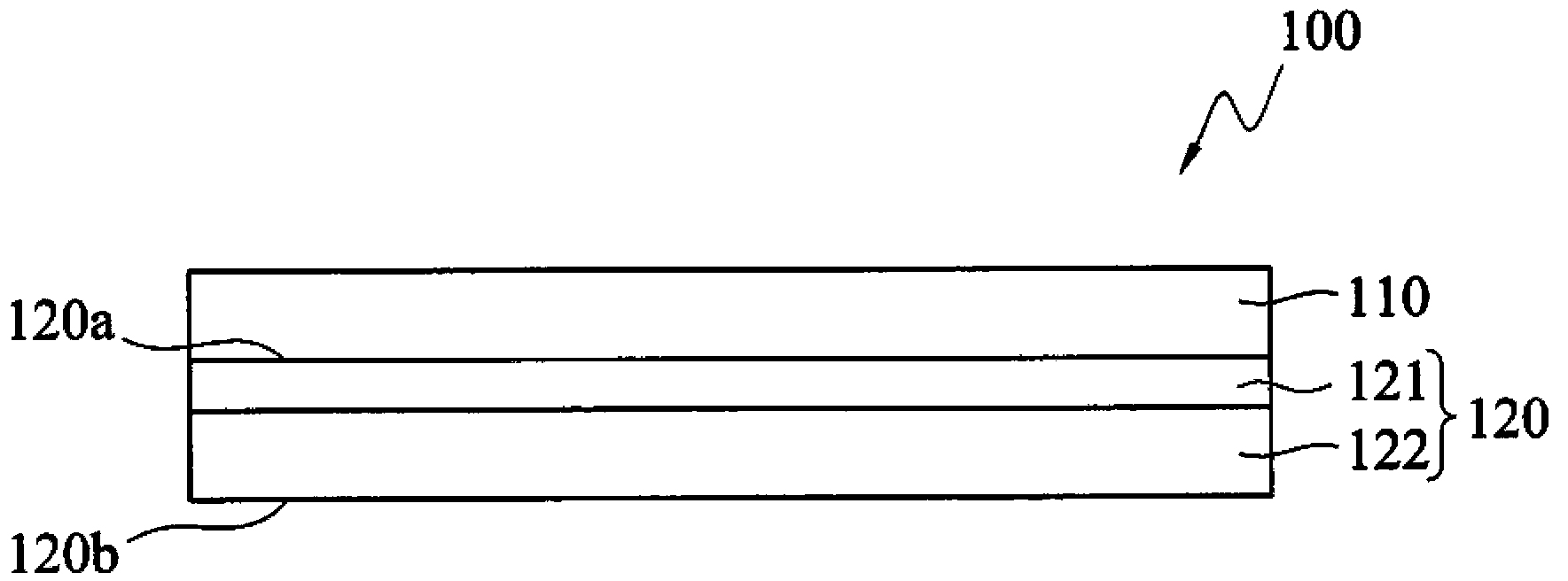

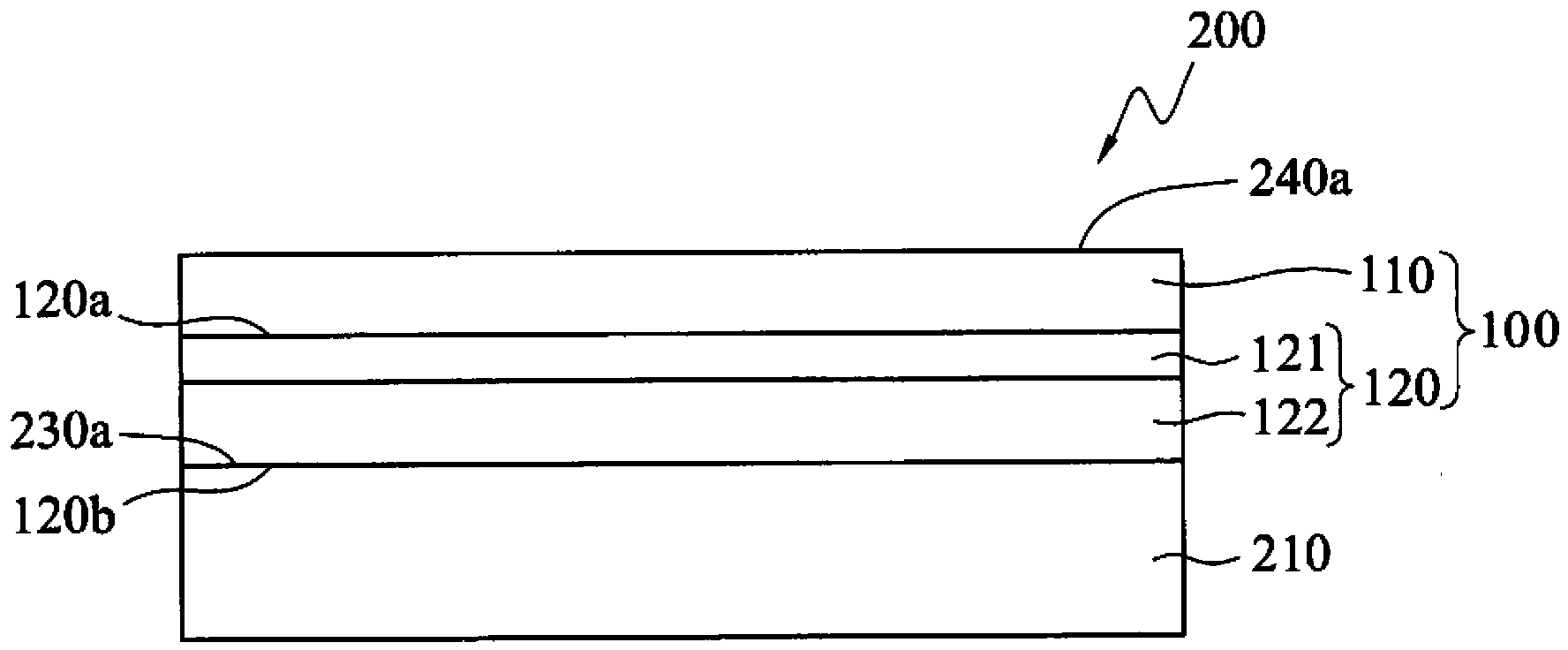

Electromagnetic wave shielding structure and flexible printed circuit board with same

A shielding structure and electromagnetic wave technology, applied in printed circuit parts, magnetic/electric field shielding, electrical components, etc., can solve problems such as poor adhesion, and achieve excellent insulation, high thermal stability, and good flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

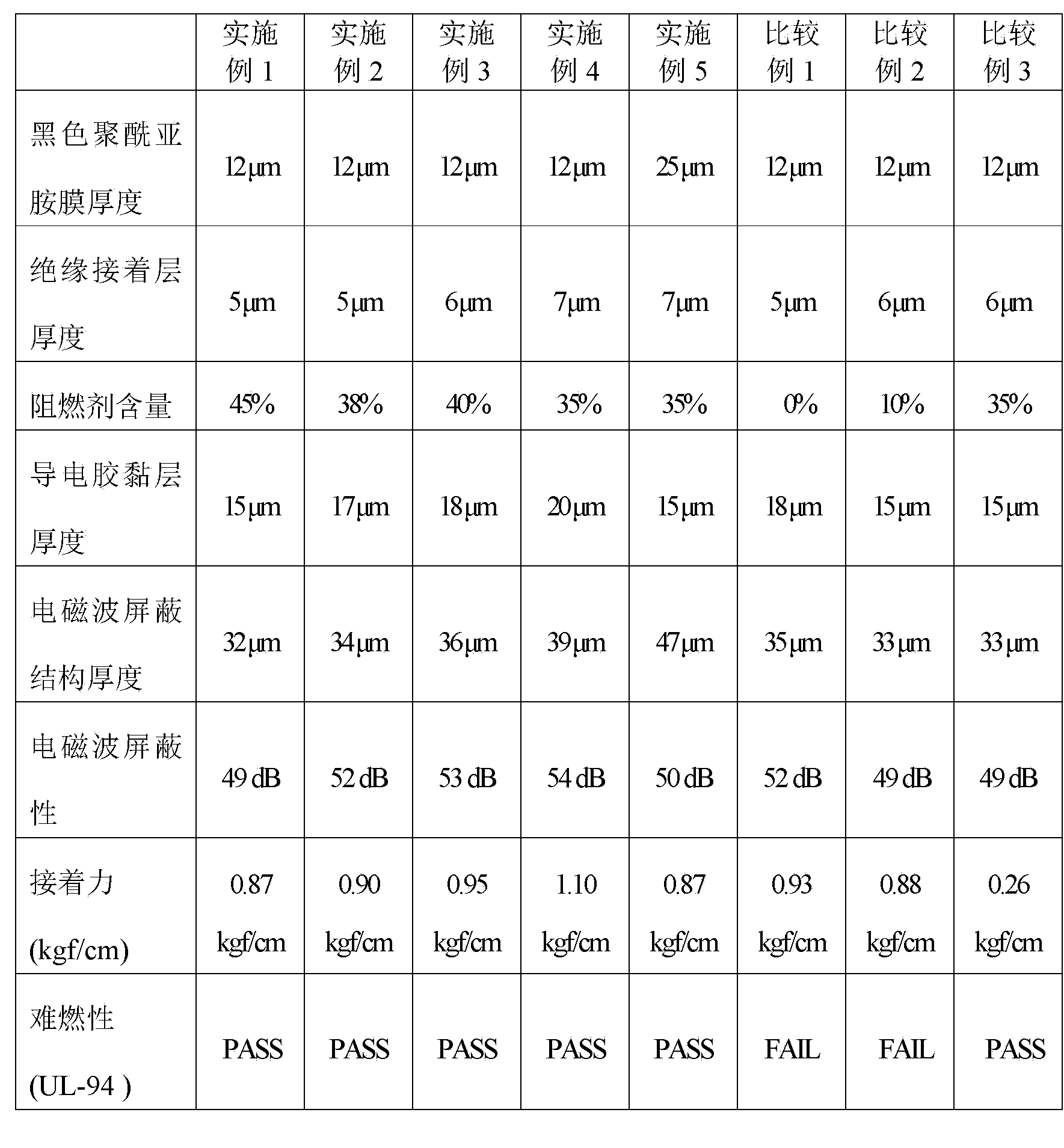

[0035]Example 1: Add propylene glycol methyl ether and methyl ethyl ketone to 30 mass parts of thermosetting epoxy resin mixture, 14.5 mass parts of diethylaluminum phosphate powder (Klein Company) and 10 mass parts of aluminum hydroxide powder as a flame retardant Mix solvent (PGME / MEK= 1 / 2) to dilute, disperse and evenly mix the above additives to form an insulating adhesive with a total solid concentration of 30 weight ratio. Lay on black polyimide film (Damaic) and dry to form an insulating adhesive layer.

[0036] In addition, 30 parts by mass of thermosetting epoxy resin mixture, 70 parts by mass of silver-coated copper conductive powder and a mixed solvent containing propylene glycol methyl ether and methyl ethyl ketone (PGME / MEK= 1 / 2) were uniformly mixed and diluted to a total solid concentration The conductive adhesive is 50% by weight, and it is coated on the release surface of the release layer made of polyethylene phthalate (PET), and dried to form a conductive ad...

Embodiment 2~5

[0038] Examples 2 to 5: The same steps were performed as in Example 1, except that the flame retardant content shown in Table 1 and the thickness of each layer shown in Table 1 were used in the insulating adhesive layer. The prepared electromagnetic wave shielding structure was laminated with the flexible printed circuit board, and the electromagnetic wave shielding property, the adhesion between the flexible and hard printed circuit board and the flame retardancy test results were recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com