Preparation method of PMMA (Polymethyl Methacrylate) nano vacant shells with different thicknesses

A nanometer and empty shell technology is applied in the field of preparation of PMMA nanometer empty shell materials to achieve the effects of low production cost, cheap raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

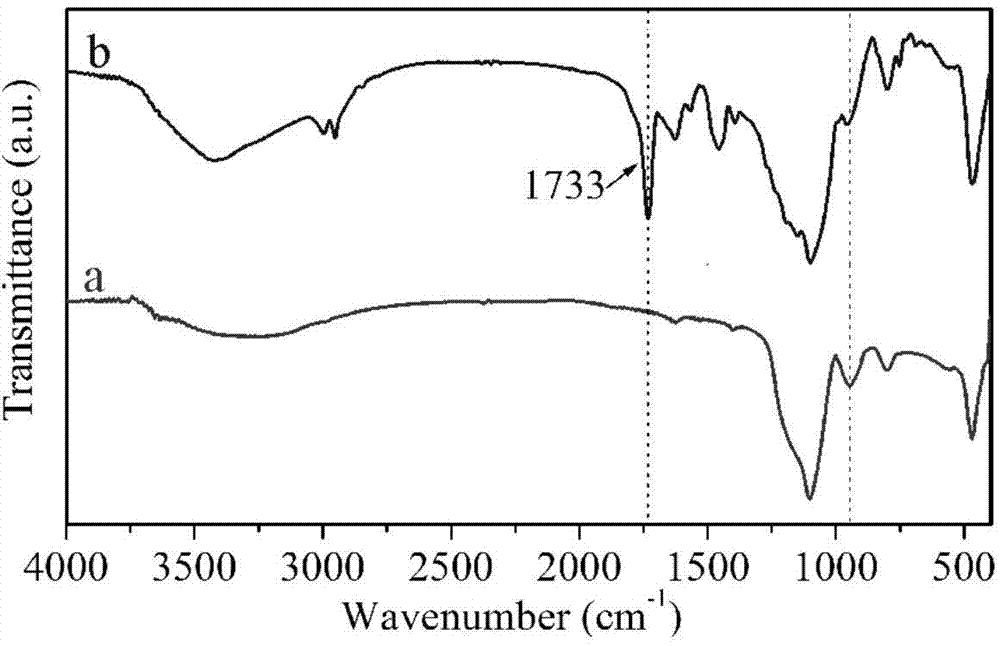

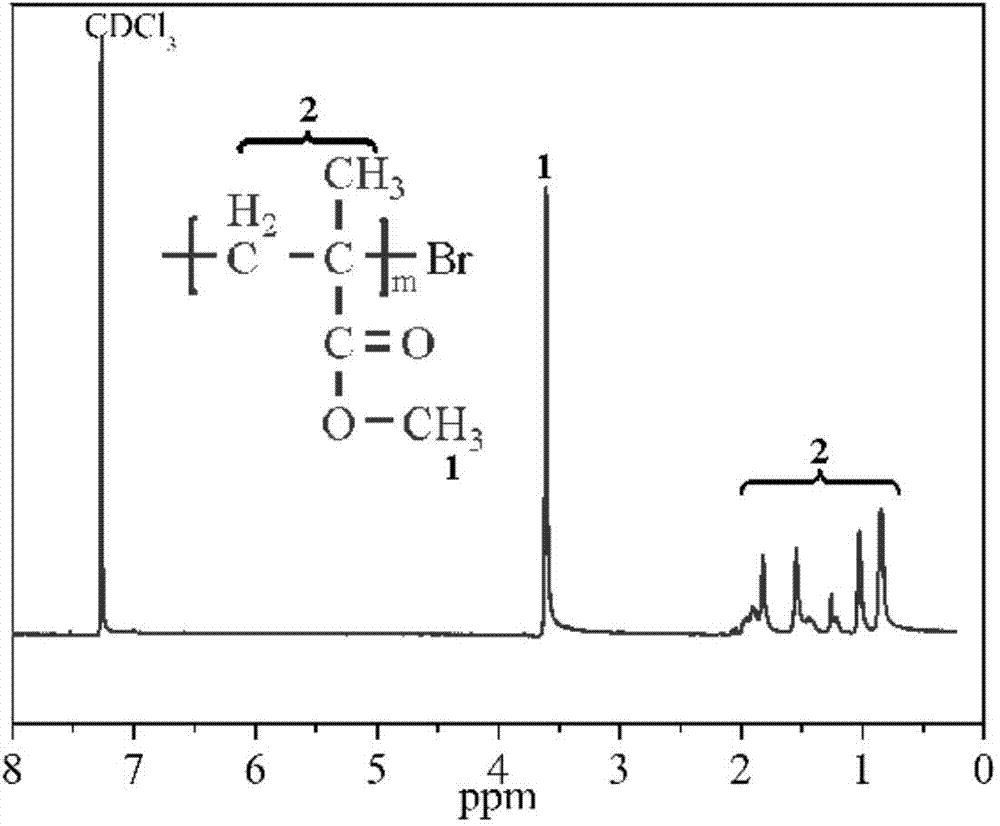

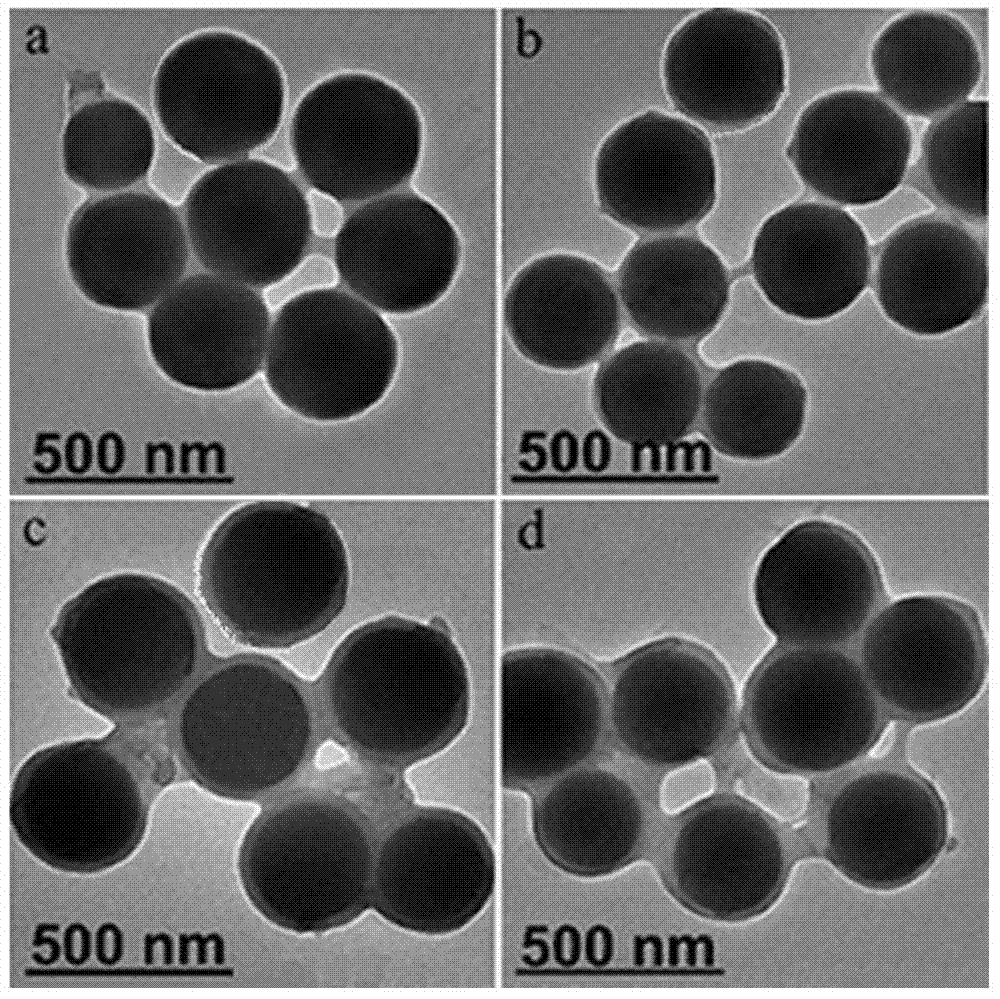

[0028] (1) Put a 100mL three-neck flask in an oil bath, add 8mL distilled water, 5mL ammonia water and 100mL absolute ethanol; add 5mL TEOS dropwise to the mixed solution under stirring, and stir at 40°C for 12h. After cooling, the obtained solution with white precipitate was centrifuged, and the obtained precipitate was repeatedly washed with distilled water, and dried at 40°C for 12 hours to obtain SiO with a suitable particle size. 2 nanospheres.

[0029] (2) Put a 100mL three-neck flask in an oil bath, add 1.0g SiO 2 , 20mL toluene, magnetically stirred and mixed evenly, 1.7g APTES was added dropwise into the flask, then the temperature was raised to 115°C and the reaction was stirred at this temperature for 18h. After cooling, the obtained solution with white precipitate was centrifuged, and the precipitate obtained after centrifugation was repeatedly washed with toluene by centrifugation. The obtained precipitate was vacuum-dried at 40°C for 12 h to obtain amino-modifi...

Embodiment 2

[0034] The difference from Example 1 is that in step (4), a 100mL three-neck flask was placed in an oil bath, and 6mL N,N-dimethylformamide (DMF), 0.25g SiO 2 -Br, 0.4g FeCl 3 ·6H 2 O, 0.74g PPh 3 After stirring evenly, pass N 2 , add 22.5mL MMA and 35μL ethyl 2-bromoisobutyrate (EBiB) to the mixed solution, after stirring evenly, slowly add the solution of 0.38g vitamin C (VC) dissolved in 3mL DMF to the above homogeneous solution, Then seal the three-neck bottle. The temperature was raised to 95°C for 12h. After cooling, the obtained solution with a light green precipitate was centrifuged, and the precipitate obtained after centrifugation was washed with DMF centrifugation. The obtained precipitate was dried under vacuum at 40 °C for 12 h to obtain SiO 2 - PMMA (ie SM2).

Embodiment 3

[0036] The difference from Example 1 is that in step (4), a 100mL three-neck flask was placed in an oil bath, and 6mL N,N-dimethylformamide (DMF), 0.25g SiO 2 -Br, 0.4g FeCl 3 ·6H 2 O, 0.74g PPh 3 After stirring evenly, pass N 2 , add 30mL MMA and 35μL ethyl 2-bromoisobutyrate (EBiB) to the mixed solution, after stirring evenly, slowly add the solution of 0.38g vitamin C (VC) dissolved in 3mL DMF to the above homogeneous solution, then Seal the three-neck bottle. The temperature was raised to 95°C for 12h. After cooling, the obtained solution with a light green precipitate was centrifuged, and the precipitate obtained after centrifugation was washed with DMF centrifugation.

[0037] The obtained precipitate was dried under vacuum at 40 °C for 12 h to obtain SiO 2 - PMMA (ie SM3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com