Pretreatment method of coking wastewater

A coking wastewater and pretreatment technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of failure to meet national discharge standards, carcinogenic and sudden organic pollutants, and effluent COD. Stability and other issues, to achieve the effect of improving COD removal rate, convenient biological treatment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The natural ferromanganese tailings are crushed into powder, sieved, and the 200-300 mesh powder is dried for use. The manganese content in the ferromanganese tailings is about 18% and the iron content is about 16%.

[0024] Under laboratory conditions, the analytically pure phenol is dissolved in water to prepare an aqueous solution of phenol with a solubility of 50 mg / L to simulate coking wastewater.

[0025] Step 1: Take 100ml of simulated coking wastewater, add 0.1g of hydrogen peroxide, and mix to obtain reaction solution 1.

[0026] Step 2: Add 0.25 g of 200-300 mesh ferromanganese tailings powder to reaction solution 1, and shake for 1.5 hours under the shaking condition of 120r / min in a shaker to obtain reaction solution 2.

[0027] Step 3: Adjust the pH value of the second reaction solution to 6-9, add 0.5 mg of polyacrylamide (PAM) for coagulation, precipitation, take the supernatant, and detect the phenol content in the supernatant by spectrophotometry.

[0028] The te...

Embodiment 2

[0030] The natural ferromanganese tailings are crushed into powder, sieved, and the powder of 200-300 mesh is dried for use. The manganese content in the ferromanganese tailings is about 18%, and the iron content is about 16%.

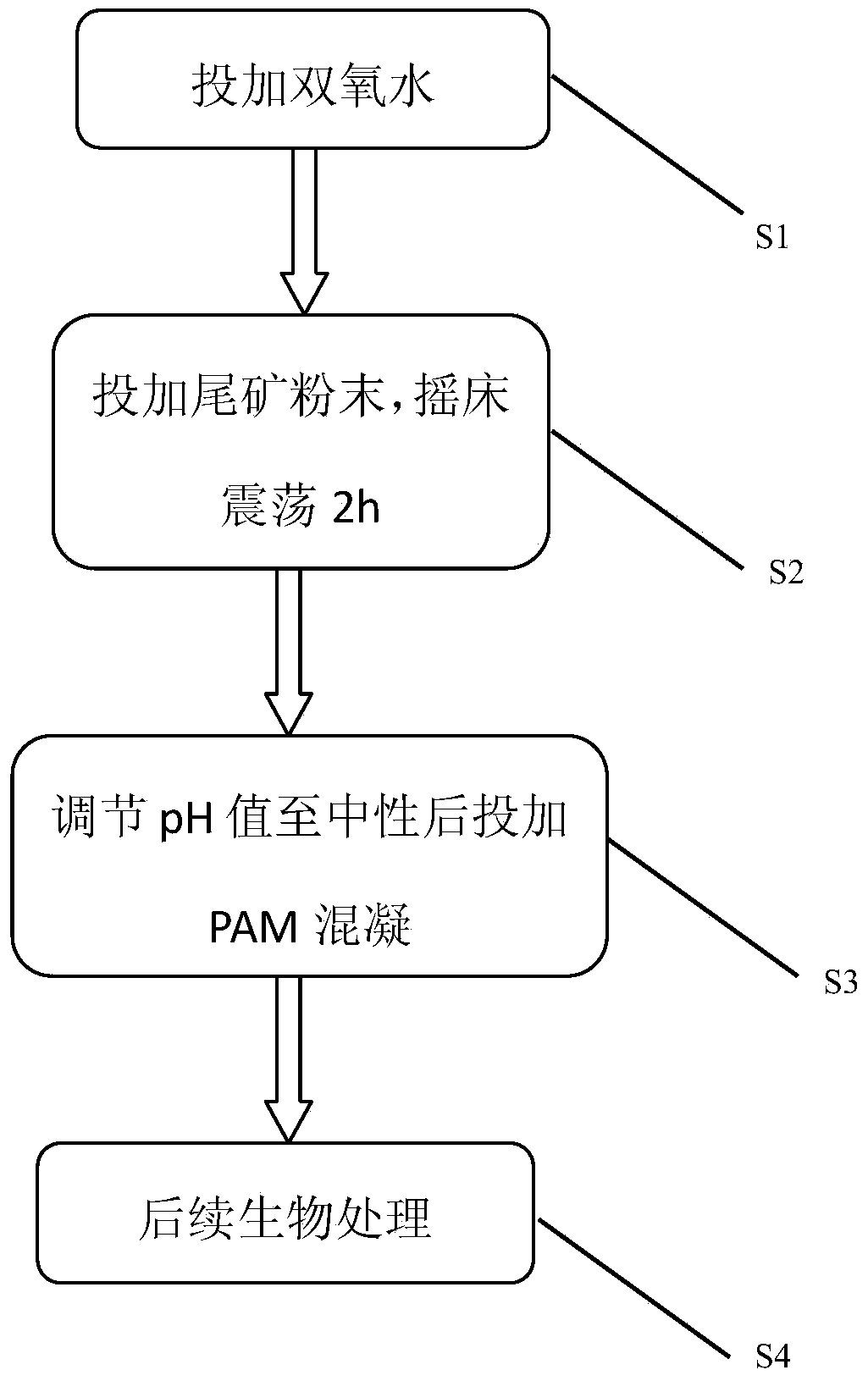

[0031] figure 1 It is the flow chart in the second embodiment of the method for pretreatment of coking wastewater involved in the present invention.

[0032] Such as figure 1 As shown, under laboratory conditions, the raw water of coking wastewater from a coking plant in Jiangnan was selected for pretreatment.

[0033] Step 1: Take 100 mL of raw coking wastewater, add 0.16 g of hydrogen peroxide, and mix well to obtain reaction solution one (S1).

[0034] Step 2: Add 0.4g of 200-300 mesh ferromanganese tailings powder to reaction solution 1, and shake for 2h under the shaking condition of 150r / min to obtain reaction solution 2 (S2)

[0035] Step 3: Adjust the pH to 6-9, add 1 mg of polyacrylamide (PAM) for coagulation, precipitation, and take the supernatant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com