Coal sulfur-fixation flame accelerator and preparation method thereof

A technology of combustion accelerator and combustion accelerator group, which is applied in the field of coal sulfur-fixing combustion accelerator and its preparation, which can solve the problems of high cost and poor sulfur-fixing effect, achieve high use efficiency, reduce environmental pressure, and increase economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Preparation example of coal sulfur fixation combustion accelerator

[0041] 1. Prepare materials according to the following components and proportions: 20 parts of alumina, 15 parts of iron oxide, 10 parts of magnesium oxide, 5 parts of silicon oxide, 8 parts of aluminum humate, 8 parts of magnesium humate, 20 parts of coal powder, 3 parts of sodium hydroxide, 1 part of potassium oxide, and 1 part of calcium hydroxide.

[0042] 2. Preparation method:

[0043] (1) Mix the above components and stir evenly;

[0044] (2) Grinding the mixture obtained in step (1) into a fine powder of 160 mesh;

[0045] (3) Divide the fine powder obtained in step (2) into separate packages.

Embodiment 2~4

[0046] Embodiment 2~4 preparation example of coal sulfur fixation combustion accelerator

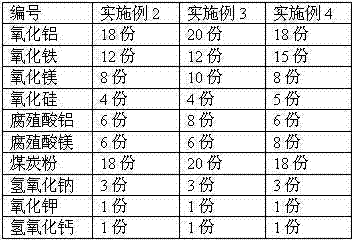

[0047] 1. Prepare materials according to the components and proportions in Table 1:

[0048] Table 1 Embodiment 2~4 components and proportioning

[0049]

[0050] 2. Preparation method: except that the number of meshes is different and shown in Table 2, the others are the same as in Example 1.

[0051] Table 2 Example 2~4 fine powder mesh number

[0052]

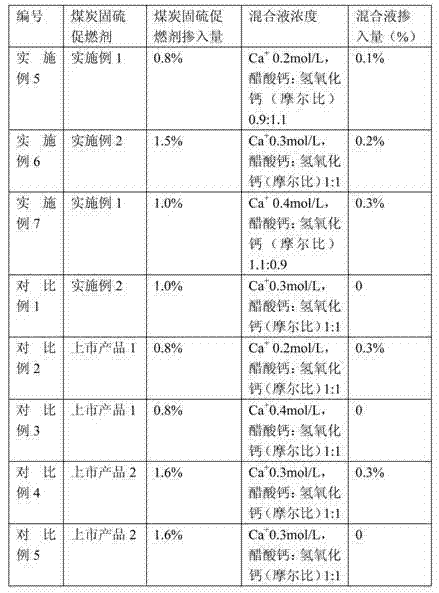

[0053] Embodiment 5~7 and comparative example 1~5

[0054] Sulfur-fixing treatment: adopt the coal-sulphur-fixing combustion accelerator prepared in Example 1, Example 2, listed product 1 or listed product 2 to carry out sulfur-fixed treatment on coal, the method is as follows:

[0055] Mix the above-mentioned coal sulfur-fixing combustion accelerator evenly into the coal before burning coal into the furnace, then add a mixture of calcium acetate and calcium hydroxide, and burn it. The mixed solution concentration of calcium ...

Embodiment 8

[0059] Example 8 Combustion promotion and sulfur fixation effect test

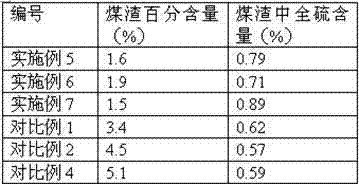

[0060]Taking the listed product 1 and the listed product 2 circulating in the market as a comparison, the percentage content of the coal slag after coal combustion in Examples 5 to 7 in the coal before combustion and the total sulfur content in the coal slag were measured.

[0061] The determination method is as follows:

[0062] 1. Collect the coal slag after combustion of Examples 5-7, Comparative Example 1, Comparative Example 2 and Comparative Example 4, and calculate the weight percentage of coal slag in the coal before combustion.

[0063] 2. Take the above-mentioned ash samples, and measure the total sulfur content in them according to the method stipulated in the national standard GB / T214 (the weight percentage of all forms of sulfur in the cinder).

[0064] The measurement results are shown in Table 4.

[0065] Table 4 Determination results of percentage content of cinder and total sulfur conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com