Preparation method for magnetic nanoparticles with surface aldehyde group functionalization

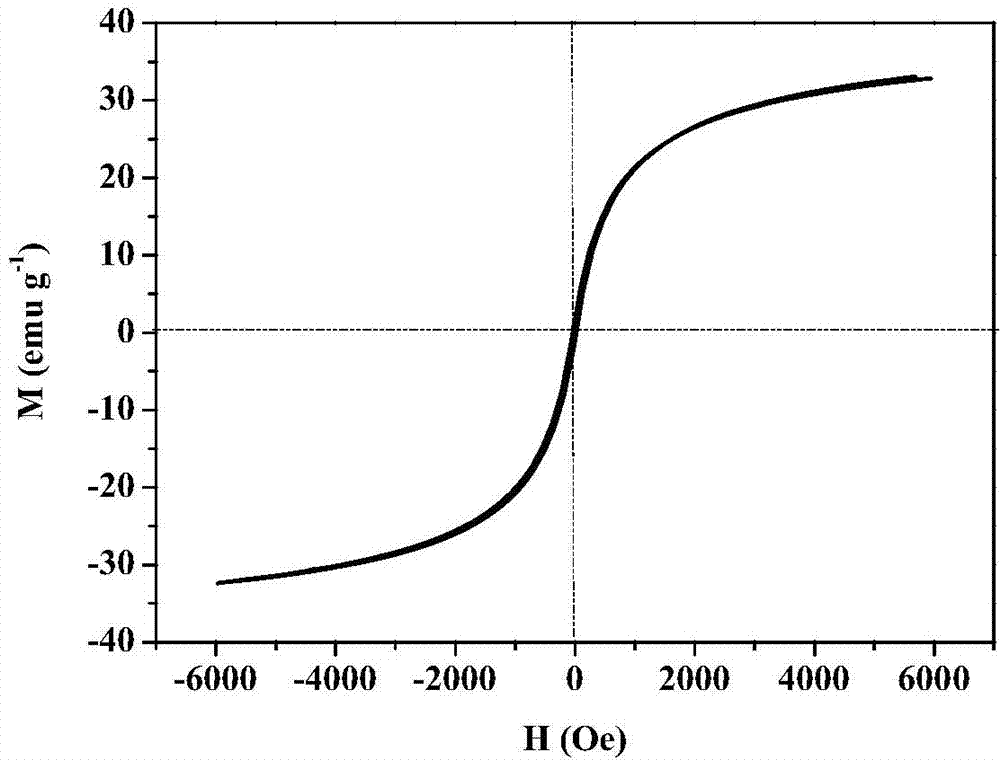

A magnetic nanoparticle and functionalized technology, applied in the field of nanomaterials, can solve the problems of easy destruction of magnetic nanoparticle structure, low chemical stability, easy oxidation, etc., and achieve rapid separation and enrichment, simple preparation method, specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of surface aldehyde functionalized magnetic nanoparticles, comprising the following steps:

[0027] 1) FeCl 3 ·6H 2 O and anhydrous sodium acetate are dissolved in ethylene glycol to obtain a uniform and transparent mixed solution;

[0028] 2) Add the surface modifier glutaraldehyde into the prepared mixed solution, stir and sonicate to obtain a homogeneous mixed solution;

[0029] 3) The mixed liquid prepared in step 2) is subjected to solvothermal reaction in an autoclave, the reaction temperature is 150-220°C, the reaction time is 6-38 hours, the reaction pressure is 1-6Mpa, and naturally cooled to room temperature after the reaction;

[0030] 4) In the presence of an external magnetic field, the solid compounds in the reaction product were separated, washed with deionized water and absolute ethanol, and vacuum-dried to obtain magnetic nanoparticles modified by surface aldehyde groups.

Embodiment 1

[0032] A preparation method of surface aldehyde functionalized magnetic nanoparticles, comprising the following steps:

[0033] (a) Weigh FeCl respectively 3 ·6H 2 O0.5g and 1.8g of anhydrous sodium acetate are placed in a 50mL beaker, add 15mL of ethylene glycol, and stir to obtain a uniform and transparent mixed solution.

[0034] (b) Measure 1.71 mL of glutaraldehyde, a surface modifier having a characteristic functional group aldehyde group, and add it to the solution obtained in step (a), stir and sonicate to obtain a homogeneous mixed solution.

[0035] (c) Transfer the solution obtained in step (b) to a sealed 30mL stainless steel autoclave with tetrafluoroethylene lining for solvothermal reaction. The reaction temperature is 200°C, the reaction time is 12h, and the reaction pressure is 1-6Mpa. End naturally cooled to room temperature.

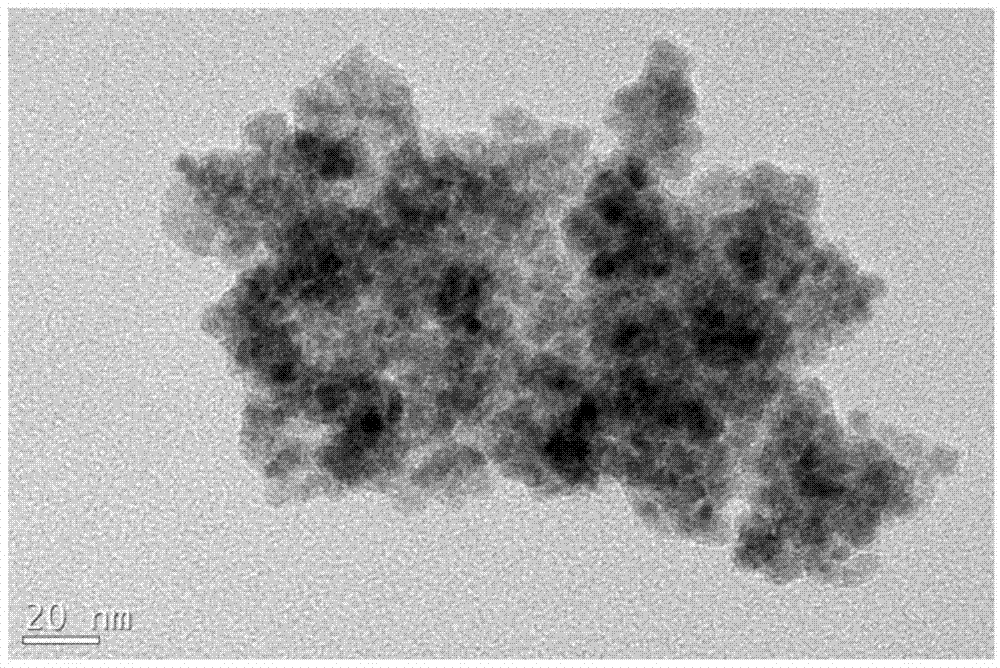

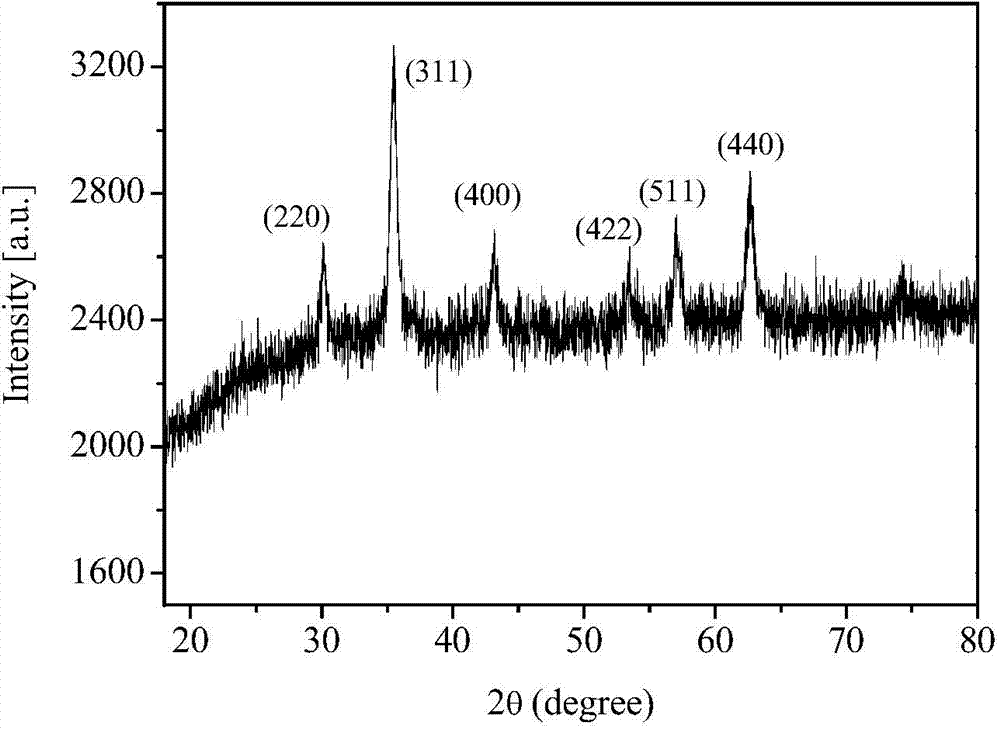

[0036] (d) After the solution is cooled to room temperature, in the presence of an external magnetic field, separate the solid comp...

Embodiment 2

[0038] A preparation method of surface aldehyde functionalized magnetic nanoparticles is as follows:

[0039] (a) Weigh FeCl respectively 3 ·6H 2 O0.5g and 1.8g of anhydrous sodium acetate were placed in a 50mL beaker, and 30mL of ethylene glycol was added, and stirred to obtain a uniform and transparent mixed solution.

[0040] (b) Measure 3.43 mL of glutaraldehyde, a surface modifier with characteristic functional group aldehyde groups, and add it to the solution obtained in step (a), stir and sonicate to obtain a uniform turbid solution.

[0041] (c) Transfer the solution obtained in step (b) to a sealed 30mL stainless steel autoclave with tetrafluoroethylene lining for solvothermal reaction. The reaction temperature is 220°C, the reaction time is 6h, and the reaction pressure is 1-6Mpa. End naturally cooled to room temperature.

[0042] (d) After the solution is cooled to room temperature, in the presence of an external magnetic field, separate the solid compound in (c)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com