Method for producing cell-grade lithium carbonate from lithium concentrate

A lithium carbonate and lithium concentrate technology, applied in lithium carbonate;/acid carbonate and other directions, can solve the problems of high impurity content of lithium carbonate, long process flow and high energy consumption, and achieve low impurity content and metal The effect of high recovery rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

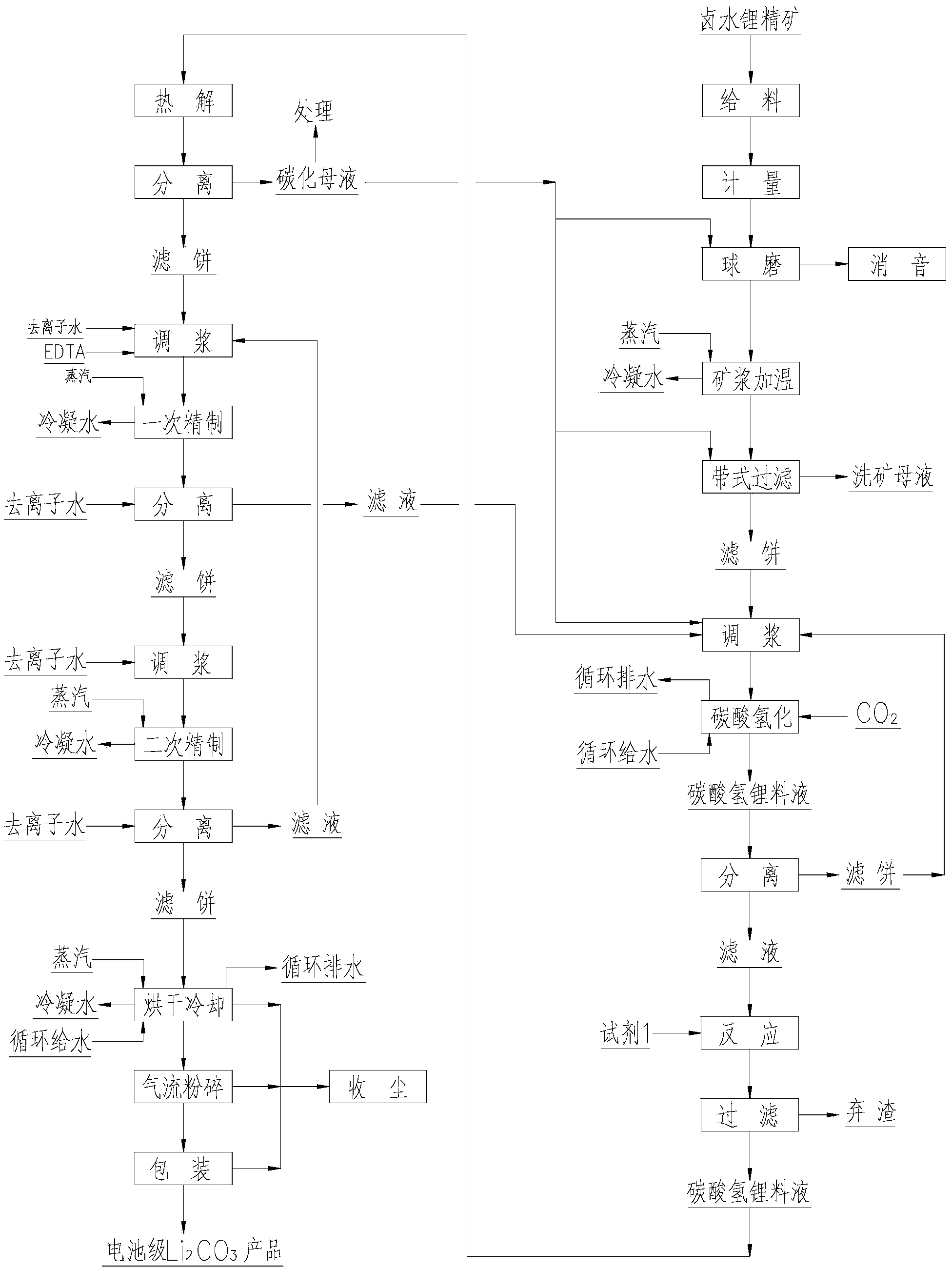

Method used

Image

Examples

Embodiment 1

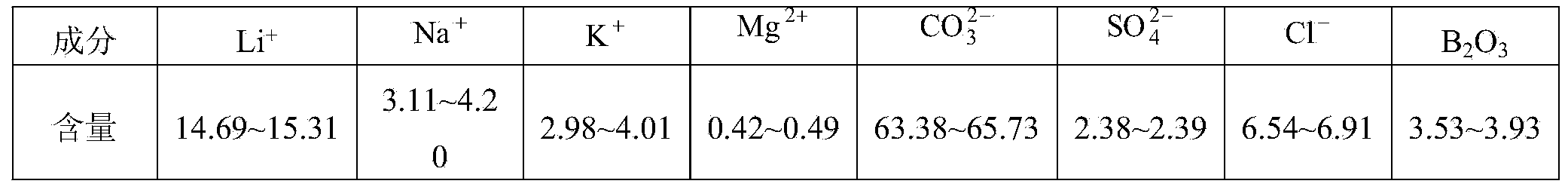

[0028] Concentrate carbonate-type brine and sulfate-type brine according to n(CO 3 2- +HCO 3 - ):n(Ca 2+ +Mg 2+ )=1.1:1 carries out bittern, the bittern after the solid-liquid separation adds sodium carbonate and separates out lithium carbonate, and the chemical composition of the bittern lithium concentrate that separation obtains is as table 2:

[0029] Table 2

[0030]

[0031] (1) Grinding: Add the brine lithium concentrate and industrial water at a ratio of 1:1 to the wet ball mill for ball milling. After ball milling, the particle size of the lithium concentrate is about 200 mesh, which is convenient for subsequent slag washing and bicarbonation.

[0032] (2) Pulp heating: The ball-milled pulp is steam-heated to 90°C in a jacketed reaction tank, stirred and kept for more than 30 minutes, and more than 99% of the soluble salt impurities in the lithium concentrate enter the solution. A vacuum belt filter with rinsing function is used to filter the pulp, and the wa...

Embodiment 2

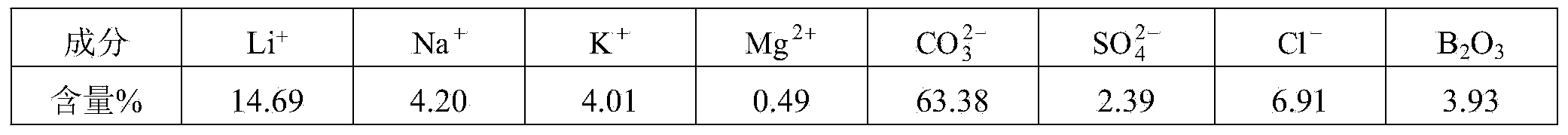

[0044] Carry out by the method for embodiment 1. Concentrate carbonate-type brine and sulfate-type brine according to n(CO 3 2- +HCO 3 - ):n(Ca 2+ +Mg 2+ )=1.2:1 carries out bittern,, the bittern after solid-liquid separation adds sodium carbonate and separates out the chemical composition of the bittern lithium concentrate that obtains as table 4:

[0045] Table 4

[0046]

[0047] (1) Grinding: Add the brine lithium concentrate and industrial water at a ratio of 1:2 to the wet ball mill for ball milling. After ball milling, the particle size of the lithium concentrate is about 300 mesh.

[0048] (2) Pulp heating: The ball-milled pulp is steam-heated to 98°C in a jacketed reaction tank, stirred and kept for more than 30 minutes, and more than 99% of the soluble salt impurities in the lithium concentrate enter the solution. A vacuum belt filter with rinsing function is used to filter the pulp, and the water content of the filtered lithium concentrate filter cake is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com