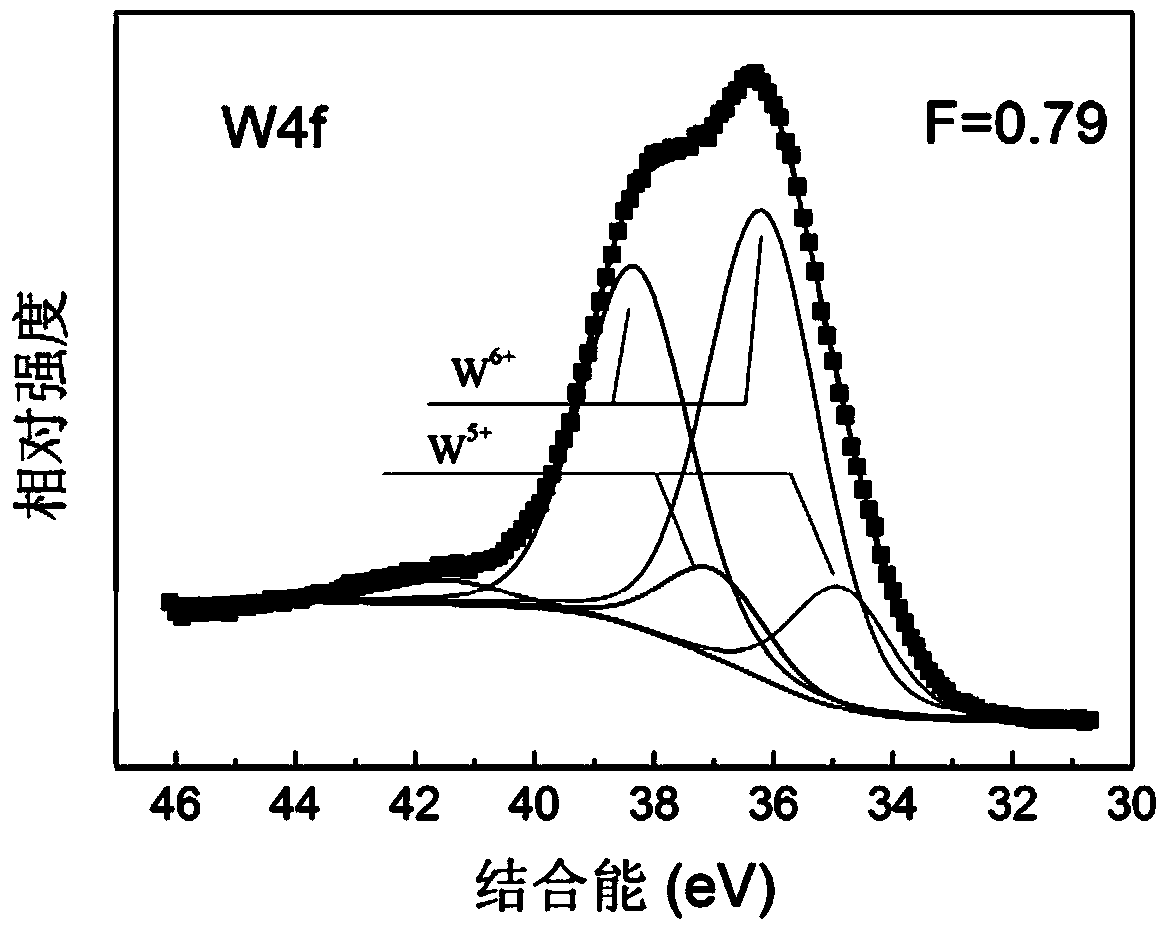

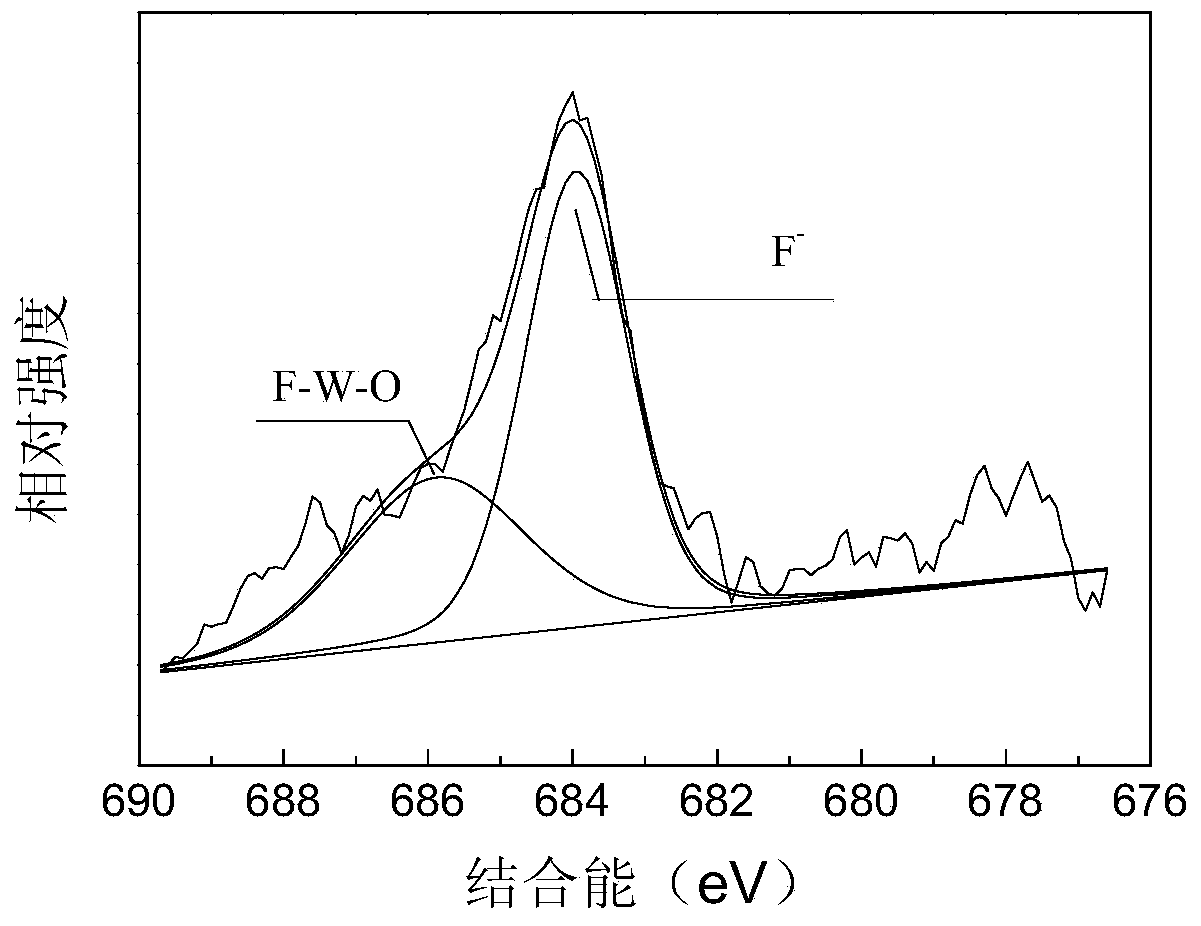

CsxWOyFz powder and preparation method thereof

A WO3-F, powder technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of inability to large-scale production, harsh reaction conditions, etc., to reduce unsafe factors, mild reaction conditions, preparation The effect of method science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The Cs x WO y f z The preparation method of the powder is hydrothermal synthesis, which specifically includes the following steps:

[0038] (1) Mix tungstic acid solution and fluorine source solution according to F / W molar ratio of 0.11~1, and keep stirring for 0.5~2h, add organic acid to form WO 3 -F composite sol, prolonging the stirring time is conducive to the full incorporation of fluoride ions;

[0039] The preparation of the tungstic acid solution comprises the following steps: washing the hydrochloric acid-activated cation exchange resin with water to neutrality, then slowly passing the sodium tungstate through the cation exchange resin, and finally obtaining a light yellow tungstic acid solution. The concentration of the tungstic acid solution is 0.25-0.75 mol / L, preferably the concentration of the tungstic acid solution is 0.5 mol / L.

[0040] The fluorine source in the present invention is hydrofluoric acid or sodium fluoride. Hydrofluoric acid and sodium...

Embodiment 1

[0060] Take the insulation material with Cs:W:F (molar ratio)=0.33:1:0.11 prepared in a 200ml autoclave as an example

[0061] 6.60g sodium tungstate Na 2 WO 4Add it to 40ml deionized water to prepare a 0.5mol / L transparent sodium tungstate solution. Then pass 40ml of sodium tungstate solution through the activated cation exchange resin to obtain light yellow tungstic acid liquid A1 with a pH of 1-1.5. Take 1ml of analytical pure hydrofluoric acid solution and add it to 102ml of deionized water to prepare 0.22mol / L hydrofluoric acid solution B1. Add 10ml of the B1 solution into the A1 solution, and keep stirring for 30-60 minutes to obtain the mixed solution A2. Take 25.4g of citric acid and add directly into the A2 solution, keep stirring until the solution is clear, then add deionized water until the volume of the solution is 100ml, and obtain the solution A3. Take 1.076g of cesium carbonate and add it into 10ml of deionized water to obtain solution C1. The C1 solution ...

Embodiment 2

[0063] Take the insulation material with Cs:W:F (molar ratio)=0.33:1:0.28 prepared in a 200ml autoclave as an example

[0064] 6.60g sodium tungstate Na 2 WO 4 Add it to 40ml deionized water to prepare a 0.5mol / L transparent sodium tungstate solution. Then pass 40ml of sodium tungstate solution through the activated cation exchange resin to obtain light yellow tungstic acid liquid A1 with a pH of 1-1.5. Take 1ml of analytical pure hydrofluoric acid solution and add it to 102ml of deionized water to prepare 0.22mol / L hydrofluoric acid solution B1. Add 25.5ml of the B1 solution into the A1 solution, and keep stirring for 30-60 minutes to obtain the mixed solution A2. Take 25.4g of citric acid and add directly into the A2 solution, keep stirring until the solution is clear, then add deionized water until the volume of the solution is 100ml, and obtain the solution A3. Take 1.076g of cesium carbonate and add it into 10ml of deionized water to obtain solution C1. The C1 soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com