Highlight acrylic ester emulsion for pigments and preparation method therefor

A technology of acrylate and emulsion, which is applied in the field of emulsion for pigments, can solve the problem that the acrylate emulsion of bright light effect has not been developed and researched, and achieve the effect of improving scrub resistance and enhancing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of emulsion:

[0034] Methyl methacrylate, butyl acrylate, and acrylic acid were pre-mixed, and the mixed solution was poured into a 50ml constant pressure dropping funnel, stirred and mixed for later use at a speed of 300 rpm, and named as monomer a liquid.

[0035] Ammonium persulfate, diacetone acrylamide, water, stir until dissolved (diacetone acrylamide is difficult to completely dissolve), pour it into a 50ml constant pressure dropping funnel, and name the initiator dropping solution b.

[0036] Water, Fatty Alcohol Polyoxyethylene Ether Sulfosuccinate Disodium Disodium Emulsifier, Fatty Alcohol (14) Polyoxyethylene Ether (10) Emulsifier, Sorbitan Oleate Polyoxyethylene Ether Sulfosuccinate Di Sodium, heated to a temperature of about 50°C in an electric furnace, stirred to become transparent, and the speed is 300 rpm, named emulsifier aqueous phase liquid c liquid.

[0037] Take 1 / 3 of the total amount of the mixed monomer liquid a, 1 / 3 of the total a...

Embodiment 5

[0045] The glossiness of embodiment 5 gained emulsion is the highest, and its performance index is as follows:

[0046]

[0047] It can be seen from the above table that the emulsion has high solid content, good stability, and high gloss, reaching the performance index of similar products in the market. At the same time, the test shows that the emulsion has excellent storage stability, and no delamination occurs when it is stored at room temperature for six months. Gloss measurement is based on GB / T97541988 Paint and varnish Determination of the sum of specular gloss of paint films without metallic pigments.

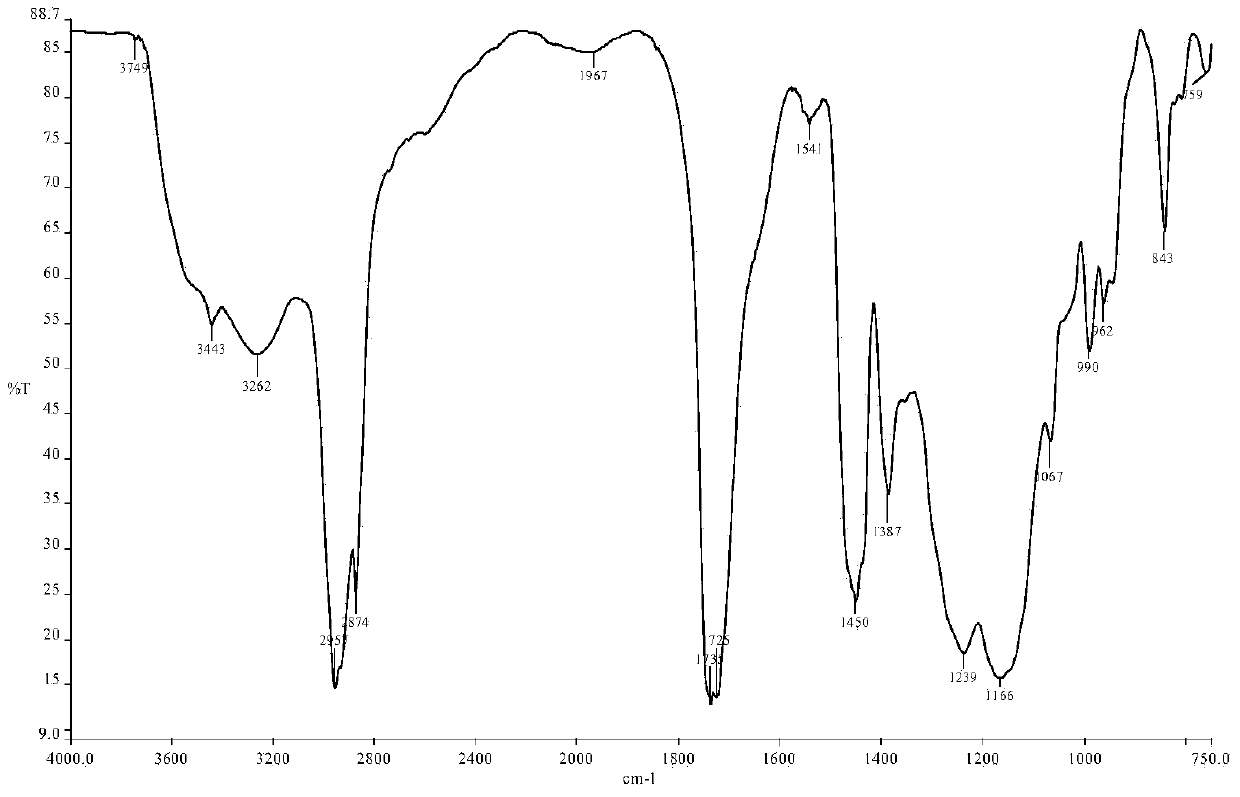

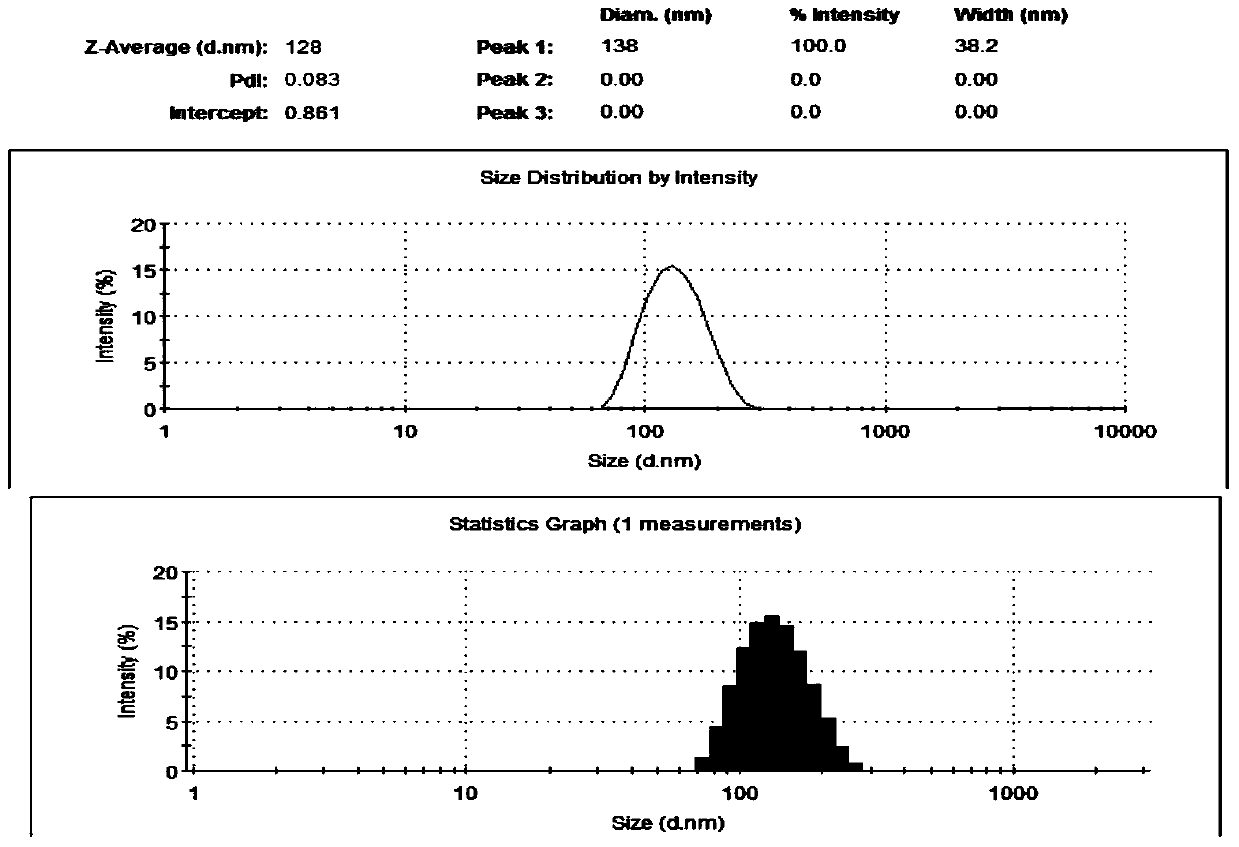

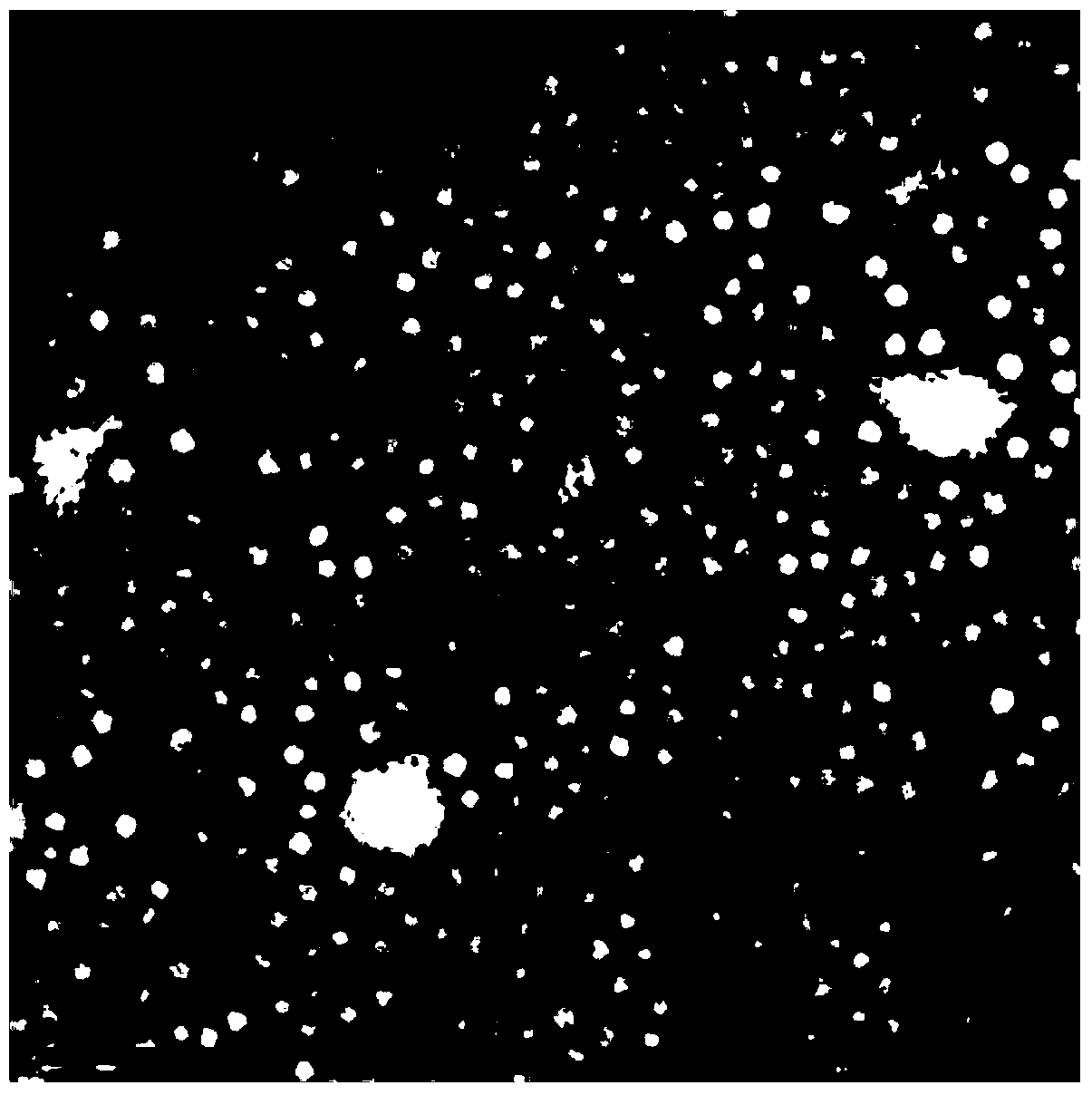

[0048] Infrared characterization of emulsion polymer structure in embodiment 5:

[0049] figure 1 Medium 2957, 2874cm -1 is CH in the copolymer 2 , CH stretching vibration absorption peak, 1735cm -1 The stretching vibration absorption peak at C=O indicates that the polymerization reaction is proceeding normally, each monomer participates in the polymerization, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com