Sugar products and fabrication method thereof

A technology for products and saccharides, which is applied in the field of low-temperature, fast and high-yield sugar products and their preparation, can solve the problems of many by-products, high equipment grade requirements, and high dilute acid hydrolysis temperature, and achieves the effect of high sugar yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

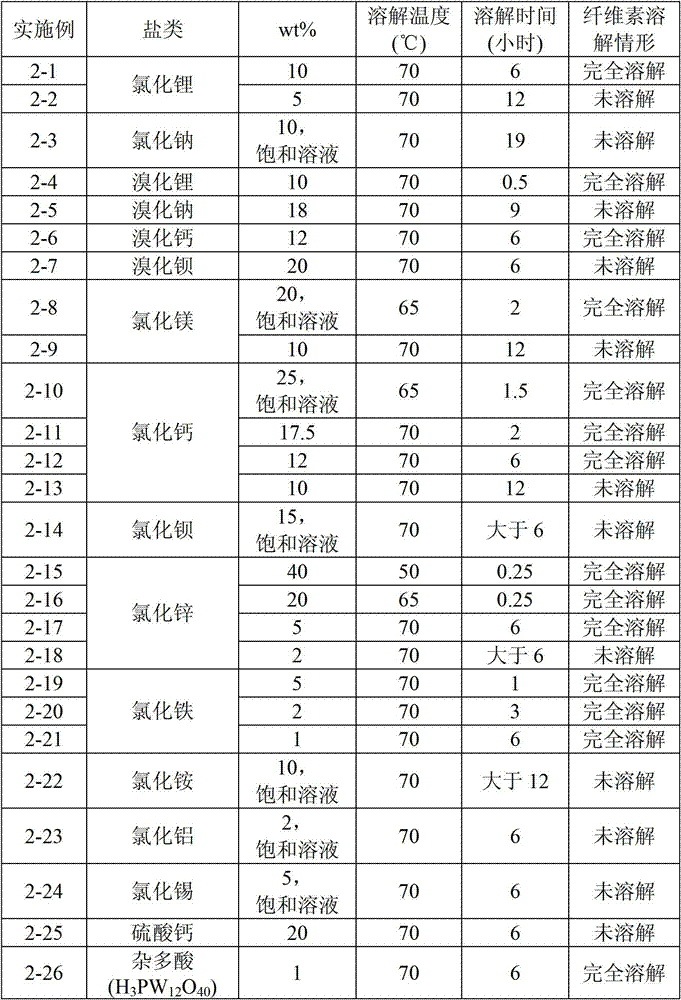

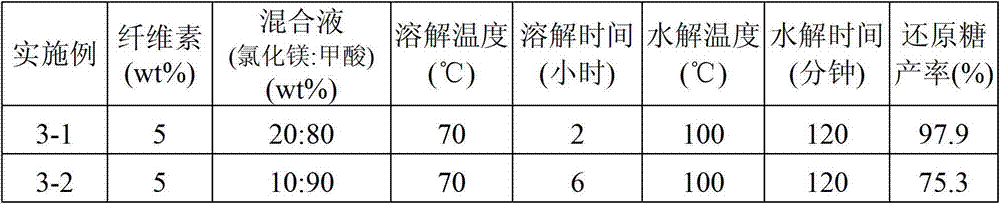

[0012] An embodiment of the present disclosure provides a method for preparing a sugar product, which includes the following steps. Firstly, formic acid is mixed with lithium, magnesium, calcium, zinc or iron chloride salts or bromide salts or heteropolyacids to form a mixed solution. Next, adding a cellulosic biomass into the mixture to carry out a dissolution reaction. Afterwards, water is added to the mixture to carry out a hydrolysis reaction to obtain a sugar product.

[0013] The weight percent of the above-mentioned formic acid in the mixed solution is generally between 60-97wt%.

[0014] The weight percentage of the lithium chloride salt or bromide salt in the mixed liquid is generally between 5-20 wt%, or 10-20 wt%.

[0015] The weight percentage of the magnesium chloride salt or bromide salt in the mixed liquid is generally between 10-30wt%, or 15-20wt%.

[0016] The weight percentage of the above-mentioned calcium chloride salt or bromide salt in the mixed liquid...

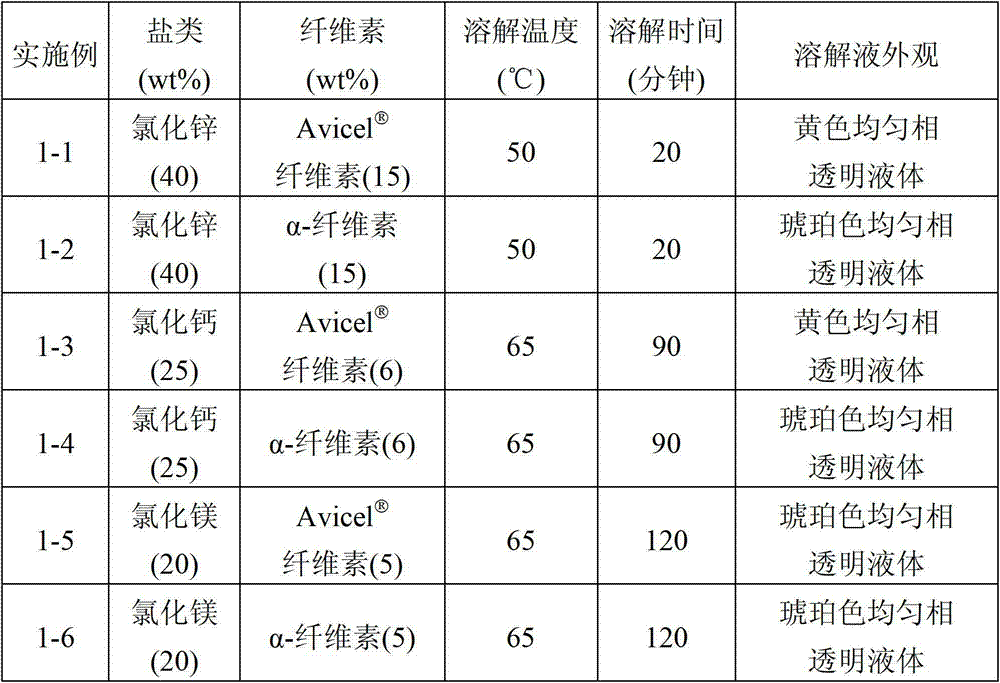

Embodiment 1-1

[0028] First, mix formic acid and zinc chloride (ZnCl2) and heat it to form a mixed solution (60wt% formic acid, 40wt% zinc chloride). Next, add Cellulose (Sigma company, Avicel-pH-105-27NI) to mixed solution ( Cellulose 15wt%), to carry out a dissolving reaction (temperature 50 ℃, time 20 minutes), form yellow homogeneous phase transparent liquid, as set forth in Table 1.

Embodiment 1-2

[0030] First, mix formic acid and zinc chloride (ZnCl 2 ) and heated to form a mixed solution (60wt% formic acid, 40wt% zinc chloride). Then, add α-cellulose (Sigma Company, C8002) to the mixed solution (α-cellulose 15wt%), to carry out a dissolution reaction (temperature 50 ° C, time 20 minutes), forming an amber homogeneous transparent liquid, as shown in the table 1 contained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com