Production method of granular biological fish fertilizer

A production method and fish fertilizer technology, which are applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of poor disease resistance, fast nutrient demand, and high breeding density of freshwater fish, so as to reduce the incidence rate and increase the total nutrients. content, increase the effect of photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

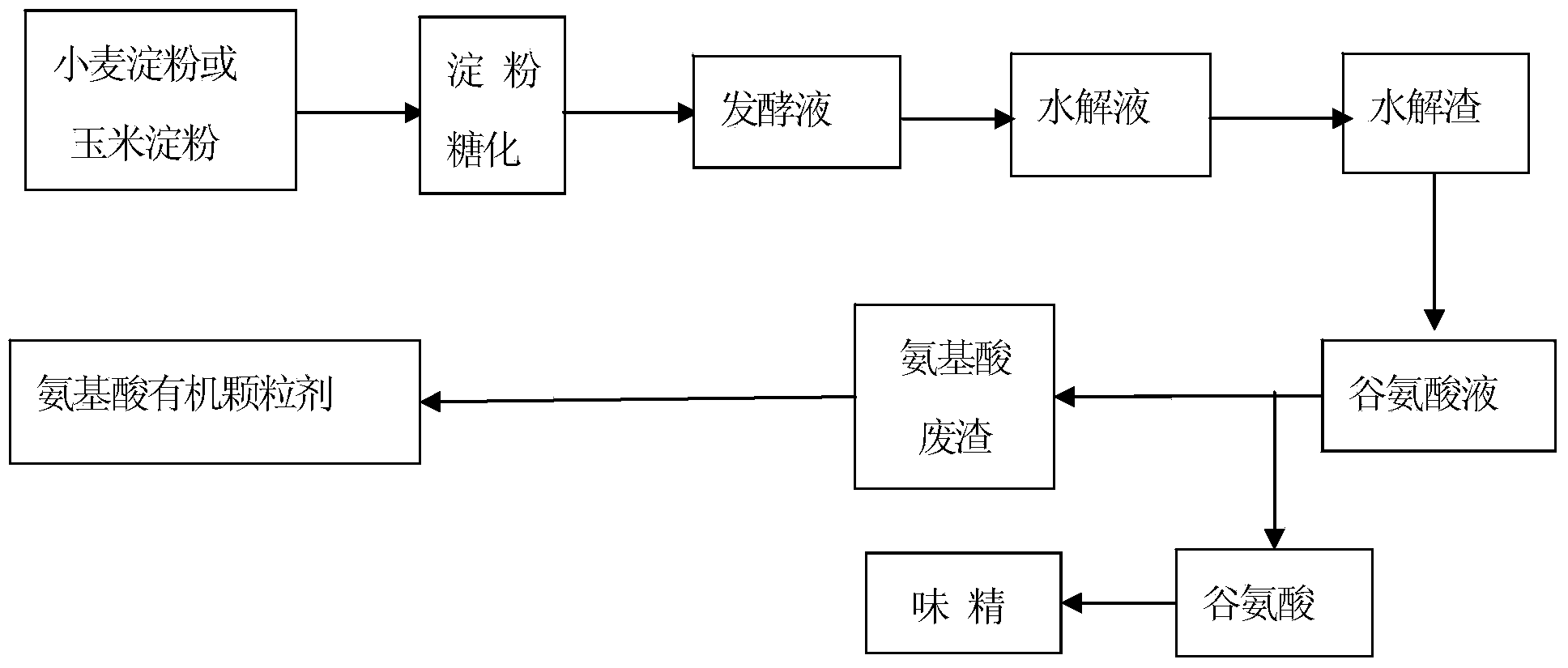

Method used

Image

Examples

Embodiment 1

[0041] 1. Sampling: Amino acid residues were collected from Lianhua Monosodium Glutamate Factory in Henan Province.

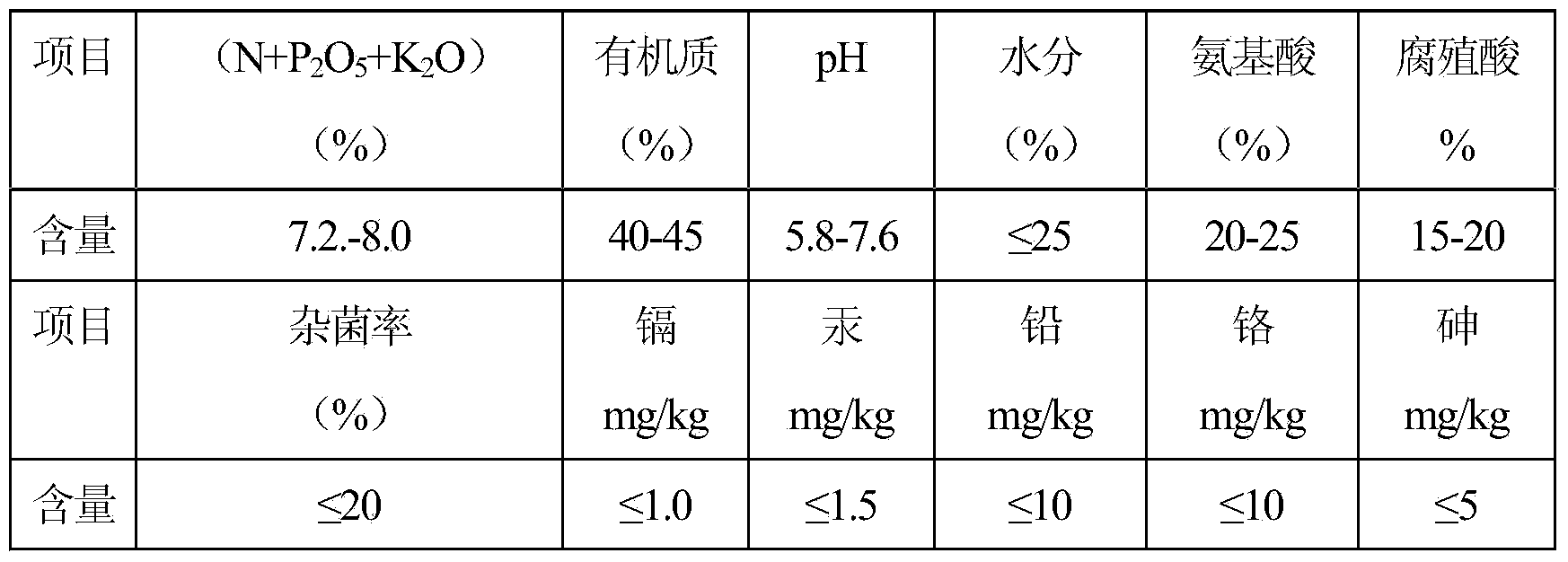

[0042] 2. Treatment of amino acid waste residue: crush large pieces of waste residue into powder or small particles, add 5% potassium hydroxide to the waste residue, mix and crush, stack the crushed mixture for 8-12 hours, and then pass it over Allow the reaction temperature to drop to room temperature to bring the pH to 5.5-7.5. The basic properties of waste residue after treatment are shown in Table 2:

[0043] Basic properties of amino acid waste residue after treatment in table 2

[0044]

[0045] 3. Granulation: The treated amino acid waste residue is subjected to drum granulation.

[0046] 4. Preparation of liquid bacterial agent: the red nonsulfur bacteria (Purple nonsulfur bacteria) and the biocontrol Bacillus subtilis (Bacillus subtilis) HL259 are fermented and produced separately by fermentation equipment, and the two single bacterial liquids are...

Embodiment 2

[0050] Except following process, other is the same as embodiment 1, makes the compound microbial fertilizer of biocontrol property produced with amino acid waste residue.

[0051] Add 6% potassium hydroxide during amino acid waste residue treatment.

[0052] Red nonsulfur bacteria (Purple nonsulfur bacteria) and biocontrol Bacillus subtilis (Bacillus subtilis) HL259 are produced by separate fermentation using fermentation equipment. The two single bacterial solutions are mixed at a ratio of 3:2 to make the mixed liquid compound microbial bacteria The total number of effective viable bacteria of the agent reaches 40.5×10 8 pcs / g.

[0053] The composite microbial bacterial agent is evenly sprayed on the surface of the organic granule in a proportion of 0.8% by weight.

Embodiment 3

[0055] Add 7% potassium hydroxide during amino acid waste residue treatment.

[0056] Red nonsulfur bacteria (Purple nonsulfur bacteria) and biocontrol Bacillus subtilis (Bacillus subtilis) HL259 are produced by separate fermentation using fermentation equipment. The two single bacterial solutions are mixed at a ratio of 2:3 to make the mixed liquid compound microbial bacteria The total number of effective viable bacteria of the agent reaches 50.5×10 8 pcs / g.

[0057] The composite microbial bacterial agent is evenly sprayed on the surface of the organic granule in a proportion of 0.7% by weight.

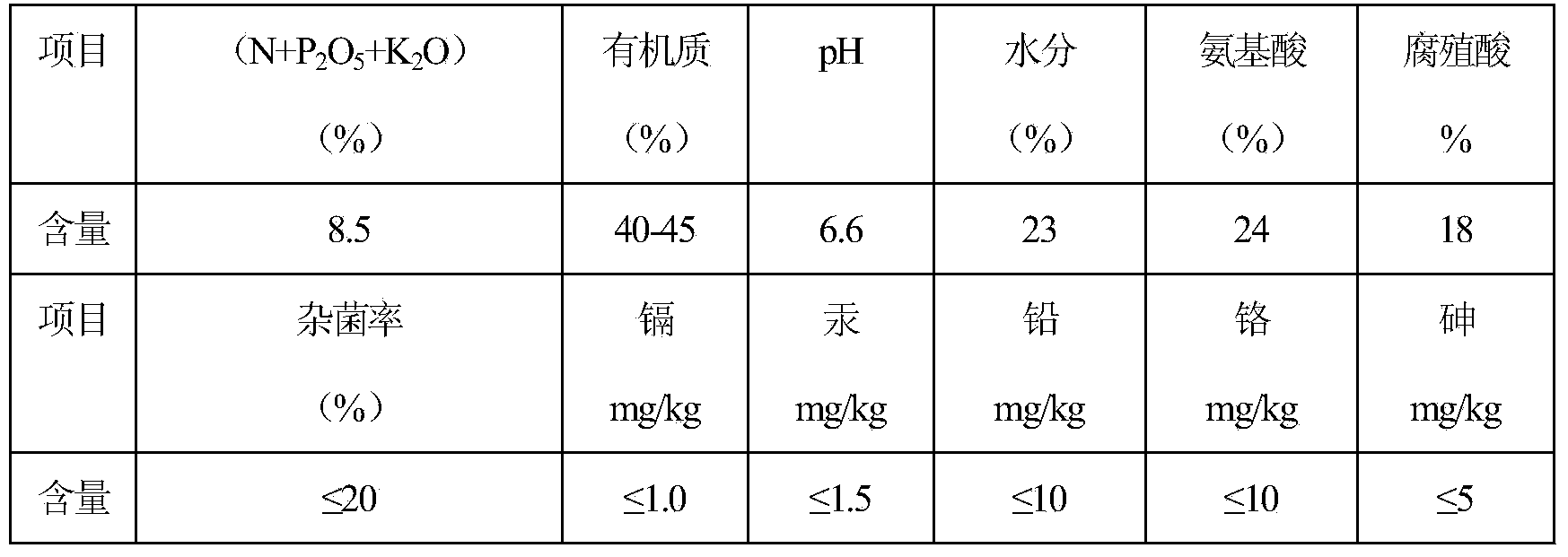

[0058] Product Quality Inspection

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com