A catalyst regeneration method for reducing carbon dioxide emissions

A carbon dioxide and catalyst technology, which is applied in the regeneration field of carbon-containing catalysts, can solve problems such as high coke and dry gas yields, and achieve the effects of reducing coke and dry gas yields, reducing investment, and reducing the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

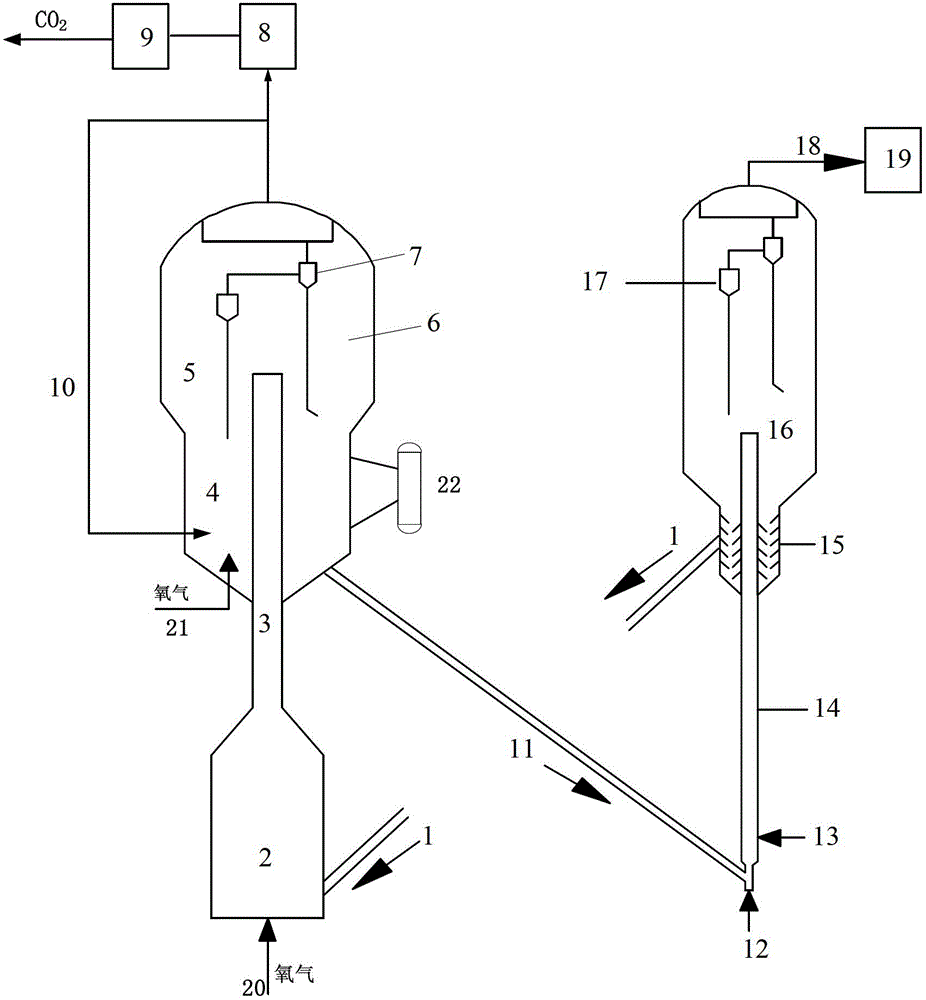

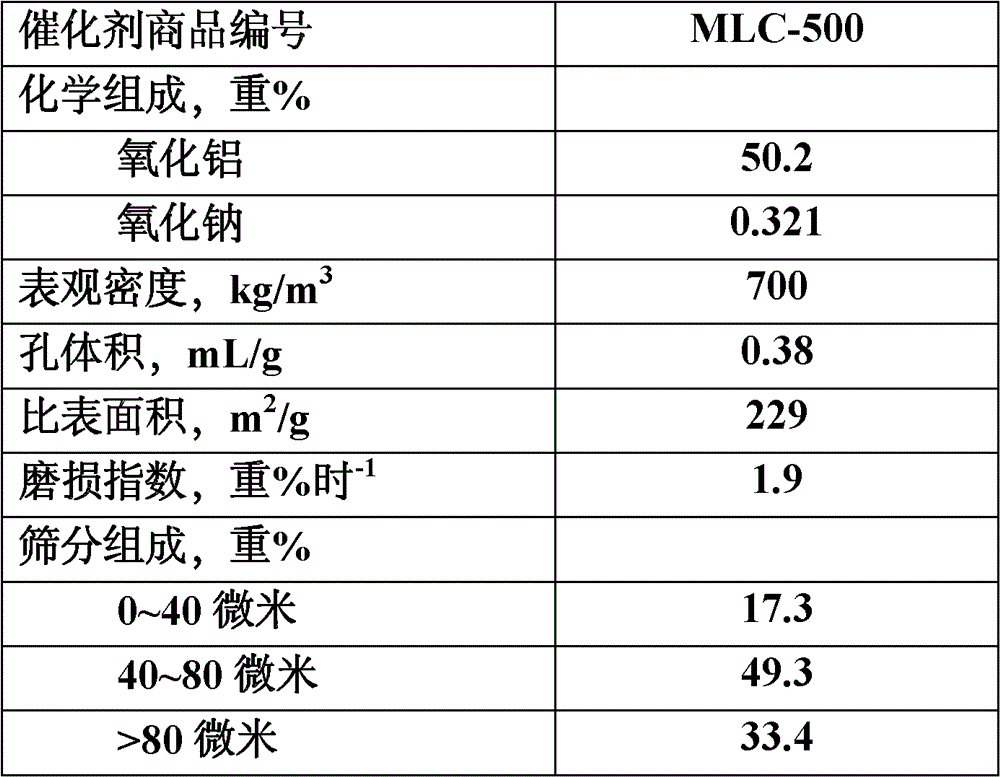

[0034] The embodiment is carried out on a catalytic cracking demonstration unit, as shown in the accompanying drawing. The demonstration plant does not have a flue gas energy recovery system and a carbon dioxide separation system. Wherein the internal diameter of the charred tank is 20 cm, and the internal diameter of the dense phase bed is 50 cm. The catalyst is regenerated according to the regeneration method proposed by the present invention, and pure oxygen gas is fed into the coke pot and the dense-phase bed respectively, and at the same time, the flue gas from the cyclone separation system of the regenerator is returned to the bottom of the dense-phase bed. The temperature of the scorching pot is 650°C, and the temperature of the dense bed of the regenerator is 640°C. The residence time of the catalyst in the burnt pot was 60 seconds, and the average residence time in the dense bed was 2 minutes. The superficial linear velocity of gas in the charred tank is 1.4m / s, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com