Photosensitive resin combination and method of preparing quantum dot pattern from photosensitive resin combination

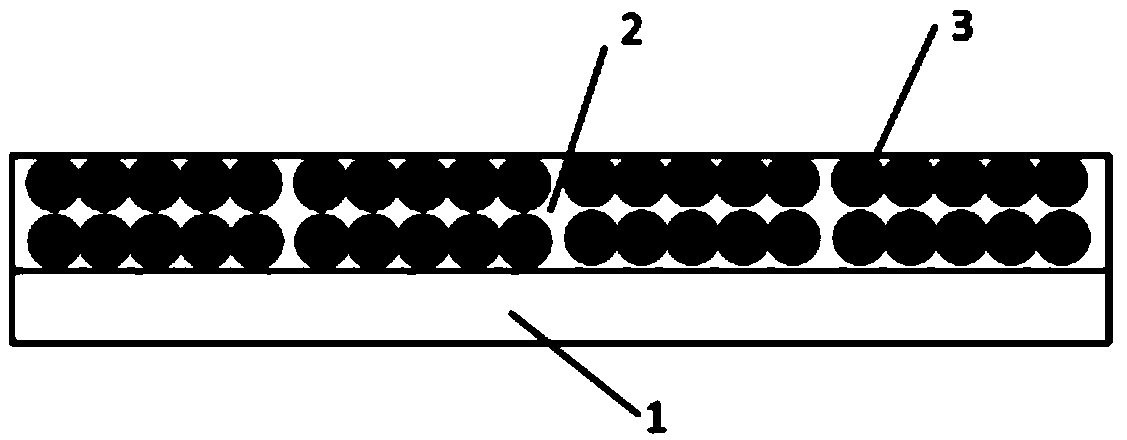

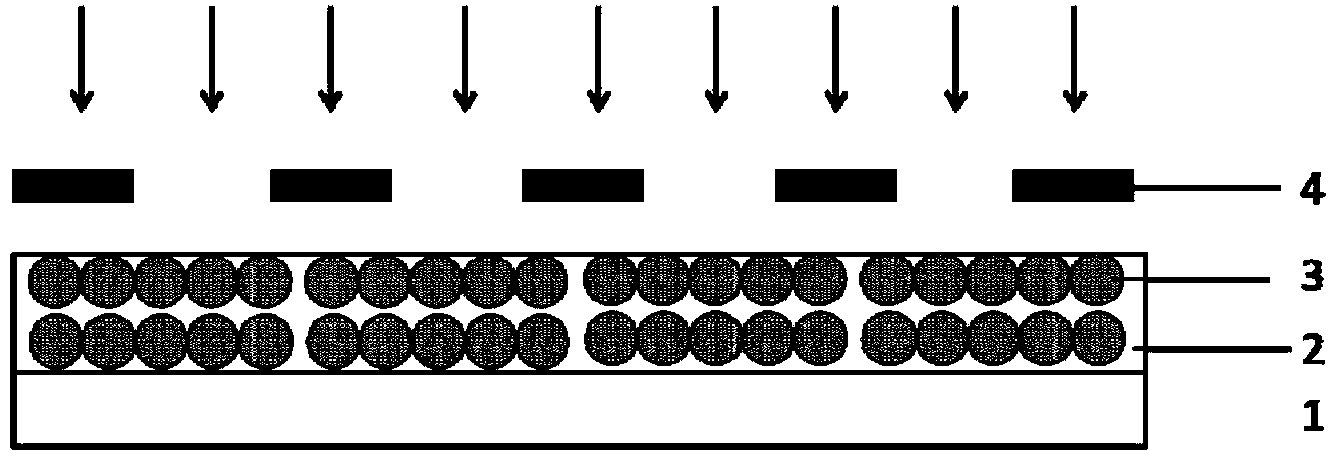

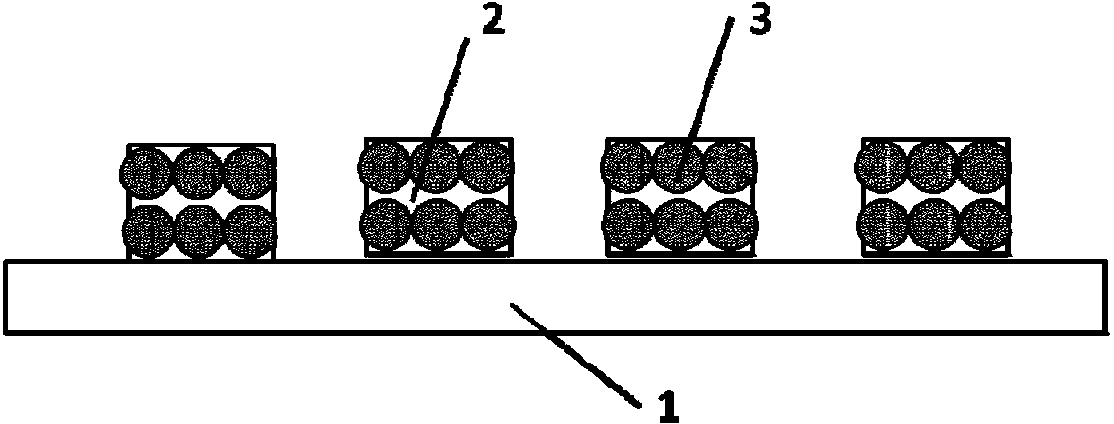

A technology of photosensitive resin and composition, which is applied in the direction of photomechanical equipment, photosensitive material processing, and photosensitive materials used in photomechanical equipment. Problems such as falling off, to achieve the effect of improving application potential, combining stability, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 20% by weight of alkali-soluble resin SB400, 10% by weight of photosensitive resin or monomer containing ethylenically unsaturated double bonds (trade name: SR494), 15% by weight of quantum dots, 2% by weight Photoinitiator (trade name: CIBA369), 0.1% by weight of silane coupling agent (trade name: KH550), 0.1% by weight of dispersant (trade name: DisperBYK160), as an auxiliary agent, 52.8% by weight The solvent propylene glycol methyl ether acetate is mixed uniformly to obtain a photosensitive resin composition.

Embodiment 2

[0045] 45% by weight of alkali-soluble resin SB400, 0.5% by weight of photosensitive resin or monomer containing ethylenically unsaturated double bonds (trade name: SR494), 4% by weight of quantum dots, 0.1% by weight Photoinitiator (trade name: CIBA369), 7% by weight of silane coupling agent (trade name: KH560), 1% by weight of dispersant (trade name: DisperBYK2000), as an auxiliary agent, 42.4% by weight The solvent propylene glycol methyl ether acetate is mixed uniformly to obtain a photosensitive resin composition.

Embodiment 3

[0047] 5% by weight of alkali-soluble resin SB401, 18% by weight of photosensitive resin or monomer containing ethylenically unsaturated double bonds (trade name: SR295), 3% by weight of quantum dots, 3% by weight Light initiator (trade name: CIBA369), 6% by weight of silane coupling agent (trade name: KH570), 0.6% by weight of leveling agent (trade name: EB350), 64.4% by weight of solvent propylene glycol The methyl ether acetate is uniformly mixed to obtain a photosensitive resin composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com