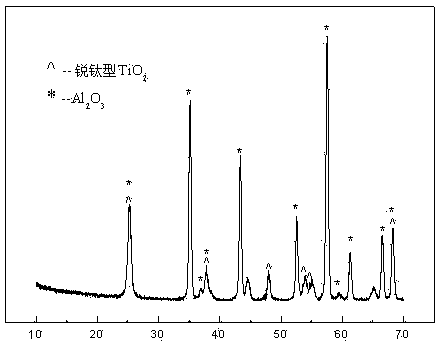

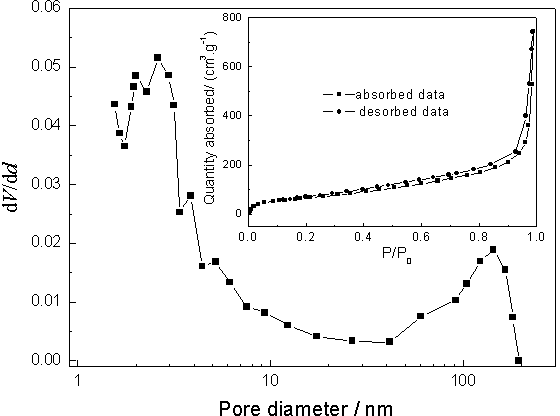

Nanocrystalline titanium dioxide film of two-specification pore structure and manufacturing method of nanocrystalline titanium dioxide film

A pore structure, titanium dioxide technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process, unfavorable industrialization, single pore size, etc. Simple process, low cost and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Mix anhydrous ethanol, tetrabutyl titanate and diethanolamine in a water bath at 30°C with continuous stirring and uniform mixing, and let stand for 30 minutes to form tetrabutyl titanate ethanol complex solution, tetrabutyl titanate and diethanolamine The molar ratio of is 1: 1.5;

[0025] (2) Mix deionized water and absolute ethanol uniformly at a volume ratio of 1:2 to form an aqueous ethanol solution, and then drop the aqueous ethanol solution into the titanic acid prepared in step (1) at a speed of 2mL / min under stirring conditions of 500rpm In the tetrabutyl alcohol complex solution, the pH value of the control solution is at 5.5, and the molar ratio of tetrabutyl titanate to water is 1: 25;

[0026] After the titration, add the non-ionic surfactant polyethylene glycol 2000, and continue to stir until the concentration is 0.3mol L -1 Titanium dioxide sol, the addition of polyethylene glycol 2000 is 1.6g / 100ml, and the temperature of the control system is 30°C...

Embodiment 2

[0030] (1) Mix anhydrous ethanol, tetrabutyl titanate and citric acid in a water bath at 35°C with continuous stirring and uniform mixing, and let stand for 30 minutes to form tetrabutyl titanate ethanol complex solution, tetrabutyl titanate and citric acid The molar ratio is 1: 2;

[0031] (2) Evenly mix deionized water and absolute ethanol at a volume ratio of 1:2 to form an aqueous ethanol solution, and then drop the aqueous ethanol solution into the titanic acid prepared in step (1) at a speed of 3mL / min under stirring at 600rpm In the tetrabutyl alcohol complex solution, the pH value of the control solution is at 6.0, and the molar ratio of tetrabutyl titanate to water is 1:30;

[0032] After the titration, add the non-ionic surfactant polyethylene glycol 2000, and continue to stir until the concentration is 0.45mol L -1 Titanium dioxide sol, the amount of polyethylene glycol 2000 added is 2.0g / 100ml, and the temperature of the system is controlled at 30°C during the who...

Embodiment 3

[0037] (1) Mix anhydrous ethanol, tetrabutyl titanate and acetylacetone under the condition of 40°C water bath with continuous stirring and uniformity, and let stand for 30 minutes to form tetrabutyl titanate ethanol complex solution, tetrabutyl titanate and acetylacetone The mol ratio is 1: 5;

[0038] (2) Mix deionized water and absolute ethanol uniformly at a volume ratio of 1:4 to form an aqueous ethanol solution, and then drop the aqueous ethanol solution into the titanic acid prepared in step (1) at a speed of 4mL / min under stirring at 700rpm In the tetrabutyl alcohol complex solution, the pH value of the control solution is 6.5, and the molar ratio of tetrabutyl titanate to water is 1: 35;

[0039] After the titration, add the non-ionic surfactant polyethylene glycol 2000, and continue to stir until the concentration is 0.5mol L -1 Titanium dioxide sol, the addition of polyethylene glycol 2000 is 2.5g / 100ml, and the temperature of the control system is 40°C during the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com